A kind of shock absorber for automobile transmission shaft

A technology of transmission shaft and shock absorber, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problem of separation of inner ring and rubber layer, unreliable bonding between inner ring and rubber, affecting vibration reduction effect and other issues, to achieve the effect of saving manufacturing processes, avoiding health damage, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

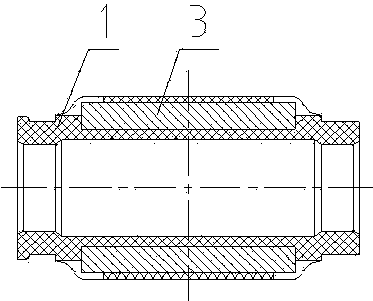

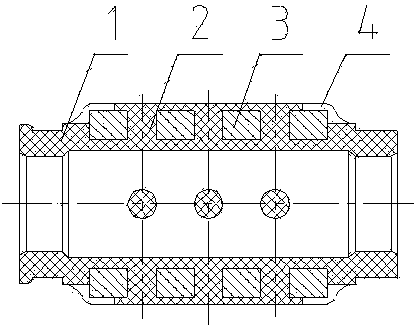

[0022] figure 2 , image 3 Among them, Embodiment 1 of the present invention includes a vibration damping body 1 and an inner ring 3 inside the vibration damping body 1 . The inner ring 3 is provided with a radial cavity 2 for filling rubber. The radial cavity 2 on the inner ring 3 of the present invention can ensure that the radial cavity 2 of the inner ring 3 is also filled with rubber after vulcanization, so that the rubber and the inner ring are combined into a firm whole. 4 is the positioning step.

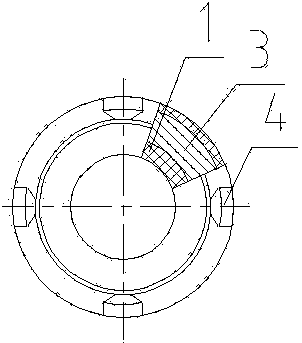

[0023] Figure 4 Among them, a positioning step 4 is provided outside the damping body 1 .

[0024] Figure 5 Among them, 3 is the inner ring, and 2 is the radial cavity.

[0025] Figure 6 Among them, Embodiment 2 of the present invention includes the damping body 1 and the inner ring 3 inside the damping body 1 . The inner ring 3 is provided with a radial cavity 2 and an axial cavity 5 for filling rubber. The axial cavity 5 may or may not communicate with the radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com