Environmental-friendly chrome-free phosphating electrogalvanized sealed steel sheet and manufacturing method thereof

A manufacturing method, electro-galvanizing technology, applied in the direction of chemical instruments and methods, superimposed layer plating, coating, etc., can solve the problems of corrosion resistance and paintability without specific instructions, achieve excellent paintability, avoid Effect of health damage, excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Test sample

[0041] Products sold in the market: plate thickness 0.6mm, double-sided electro-galvanized steel plate, and the amount of galvanizing on each side is 20g / m 2 .

[0042] 2. Cleaning of electro-galvanized steel sheets

[0043] Clean the surface of the electro-galvanized steel sheet with an aqueous solution (concentration: 20g / L) of a medium-alkaline degreasing agent (registered trademark: FC-364S, product of Japan Parker Seisei Co., Ltd.), the treatment temperature is 60°C, and the treatment time is 20 seconds , the treatment method is spraying, and then washing with tap water to remove the residual alkaline components on the surface.

[0044] 3. Phosphating treatment

[0045] (1) The electrogalvanized steel sheet that the surface has been cleaned is first dipped for 20 seconds in the surface adjustment treatment solution (PL-Z, the product of Japan Parker Seisei Co., Ltd.) diluted to 0.6g / L with water, wherein the surface adjustment treatment solution...

Embodiment 2

[0051] 1. The test sample is the same as in Example 1.

[0052] 2. The cleaning of the electrogalvanized steel sheet is the same as in Example 1.

[0053] 3. In the phosphating treatment, the concentration of the surface adjustment treatment liquid is 2.0 g / L, and the steel plate is sprayed in the phosphating treatment agent for 20 seconds.

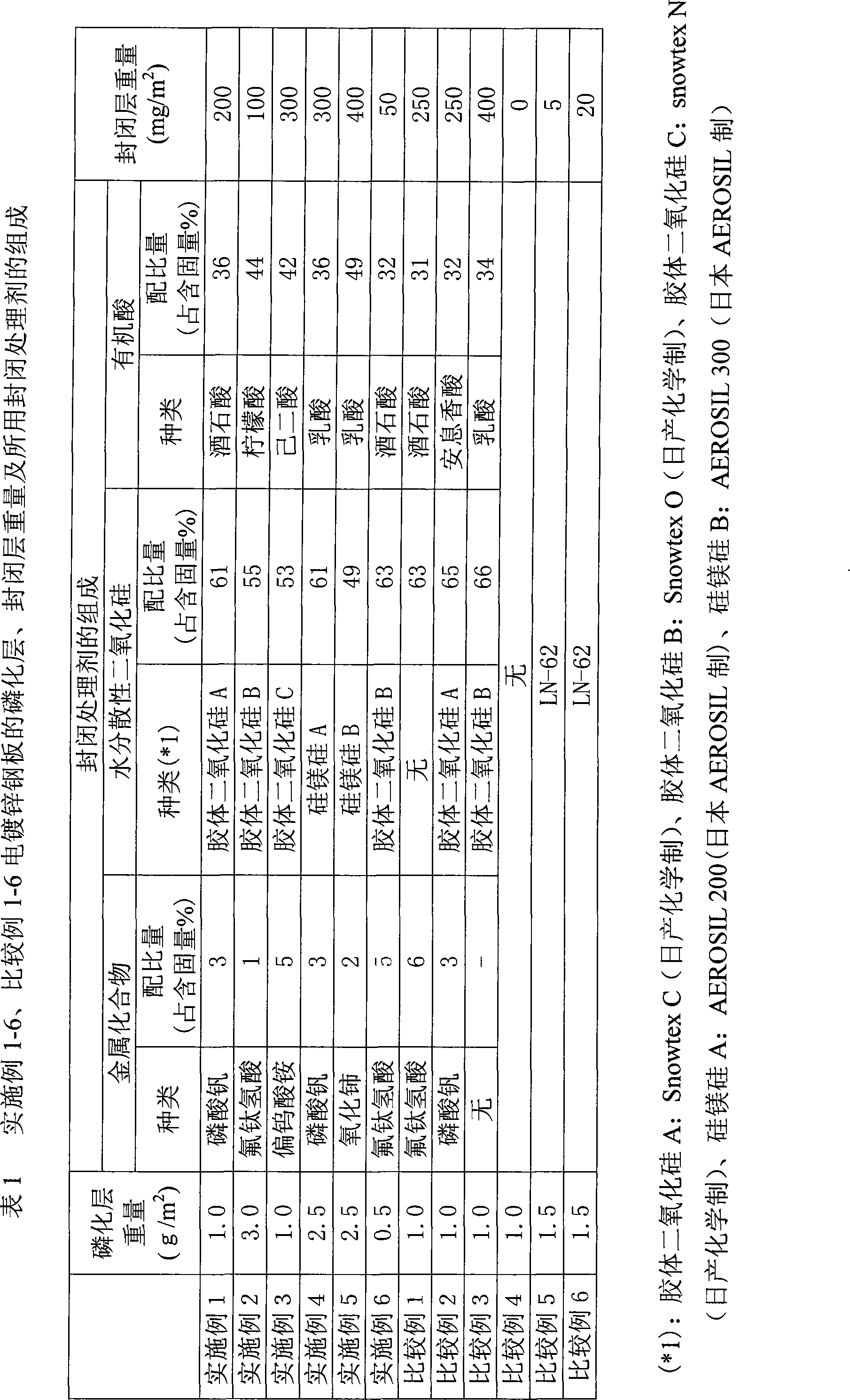

[0054] 4. See Table 1 for the composition of the sealing treatment agent and the weight of the sealing layer, and see Table 1 for other implementation methods.

Embodiment 3

[0056] 1. The test sample is the same as in Example 1.

[0057] 2. The cleaning of the electrogalvanized steel sheet is the same as in Example 1.

[0058] 3. In the phosphating treatment, the concentration of the surface adjustment treatment liquid is 0.8g / L. The steel plate is sprayed in the phosphating treatment agent for 10 seconds. The weight of the phosphating layer is shown in Table 1.

[0059] 4. See Table 1 for the composition of the sealing treatment agent and the weight of the sealing layer, and see Table 1 for other implementation methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com