Modular coal automatic sample preparation analysis system and method

An automatic sample preparation and analysis system technology, applied to the analysis of materials, instruments, etc., can solve the problems of great harm to human health, poor working environment, and high noise, and achieve the effect of no manual operation error, convenient operation, and guaranteed analysis data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

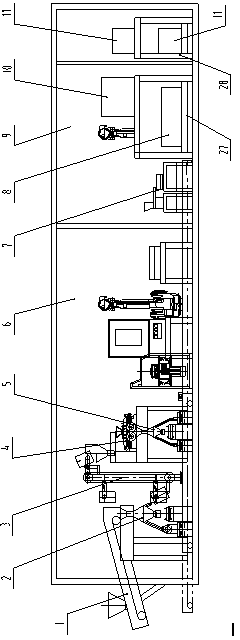

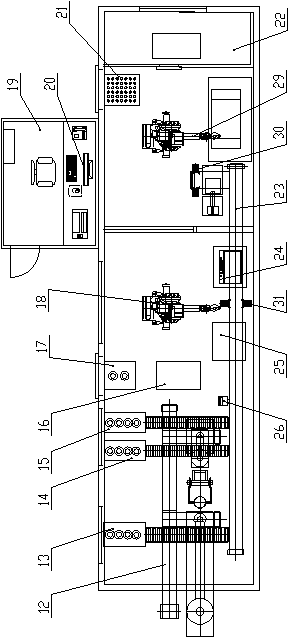

[0011] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0012]As shown in Fig. 1 and Fig. 2, the modular coal automatic sample preparation and analysis system of the present invention is mainly composed of three parts: a sample preparation unit, an analysis unit and a control unit; The primary feeder 1, the first-stage shrinkage device 2 connected with the primary feeder 1, the first-stage shrinkage device 2 adopts a rotary tube type shrinkage device, which includes a rotary material distribution pipe and a discharge bottom cone, and the discharge There are 3 outlets on the bottom cone which are successively connected with the feeding port of I automatic filling conveying unit 13, discarded sample collection system 12 and bucket elevator 3. It is connected with an automatic feeding crusher 4, and a secondary shrinkage device 5 is arranged below the automatic feeding crusher 4. The shrinking device adopts a rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com