Pumps and Washing Equipment

A technology of washing chamber and drive shaft, applied in mechanical equipment, pumps, pump components, etc., can solve the problems of abnormal motor vibration, large adjustment amount, influence of motor work, etc., to reduce noise and abnormal vibration, reduce rotational inertia, Precisely controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

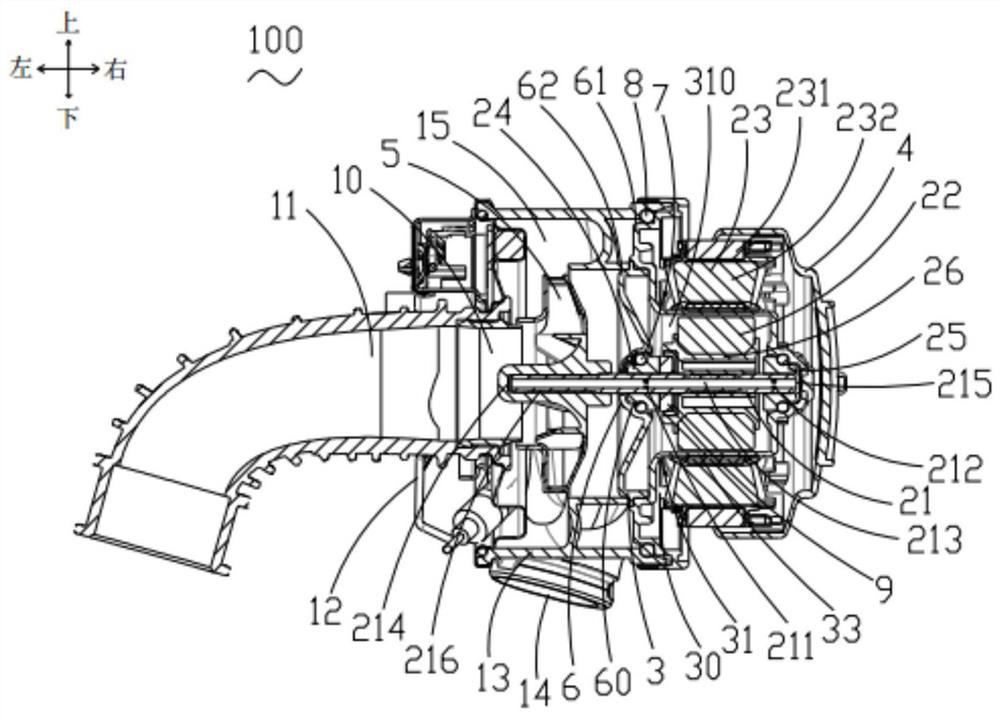

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

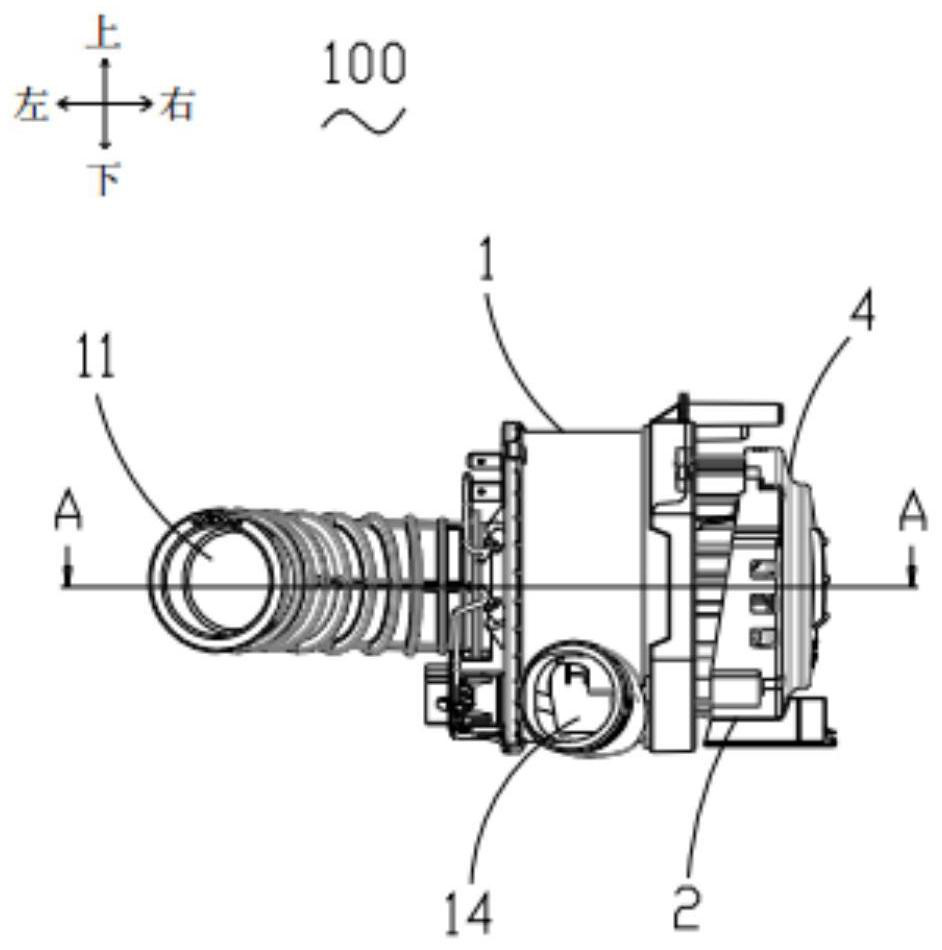

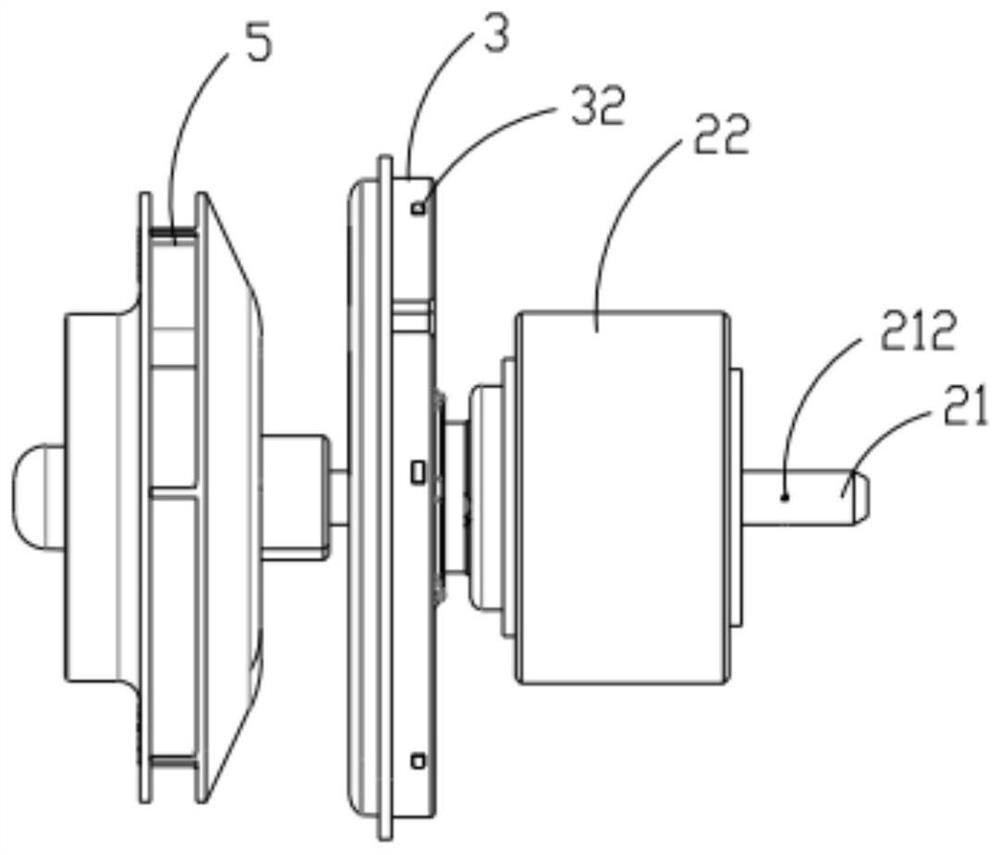

[0030] see Figure 1 to Figure 12 As shown, the present invention discloses a washing equipment, the washing equipment is provided with a pump 100, the pump 100 includes a driving device 2, a water separator 3 installed on the left end of the driving device 2, a water separator installed on the driving device 2 The casing 4 at the right end of the device 2, the impeller 5 installed on the left side of the water separator 3, and the pump casing 1 covering the outside of the impeller 5, the pump casing 1 is provided with a housing for the impeller 5 the second chamber 10 .

[0031] The driving device 2 is a DC brushless motor capable of reversing forward and reverse, and the DC brushless motor 2 includes a control circuit (not shown) for controllin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com