A high voltage pulse output device

A technology for output devices and high-voltage pulses, which is applied in the direction of output power conversion devices and electrical components, can solve the problems of short insulation distance along the surface of the coaxial output structure and limited coaxial stability, etc., to achieve long-term stability and reduce Average dielectric constant, effect of reducing installation requirements and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings. Obviously, the described embodiments are not a limitation of the present invention.

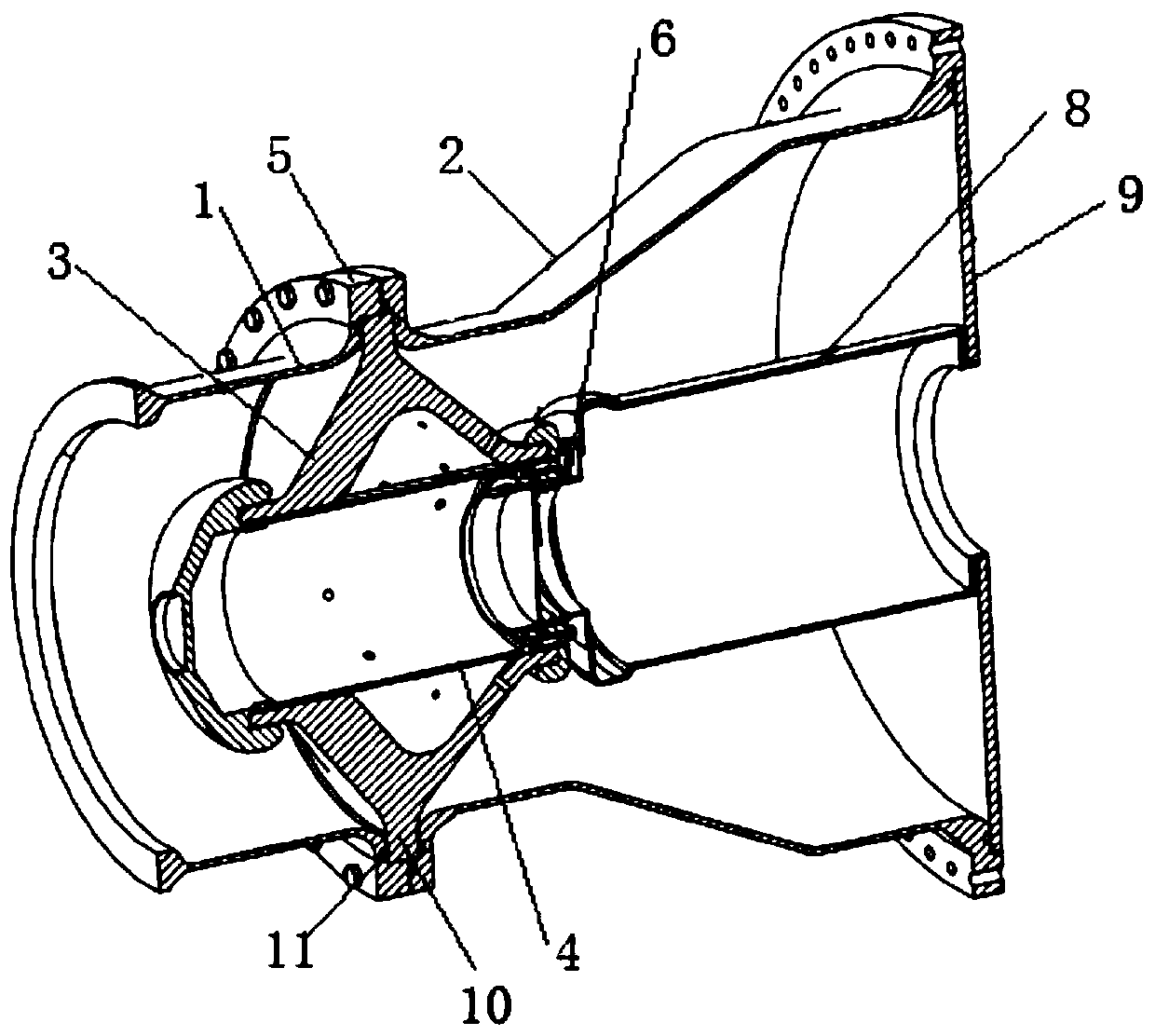

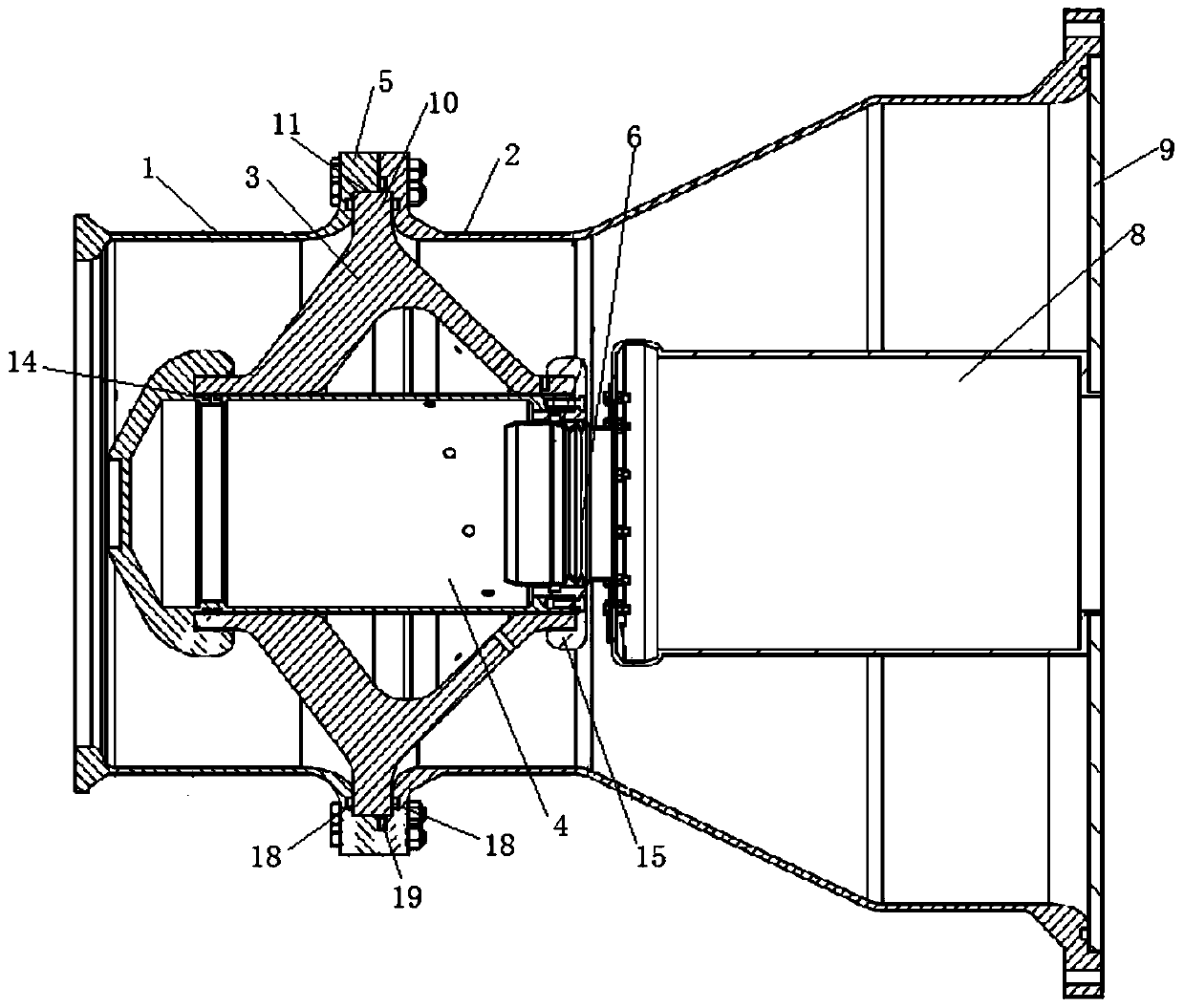

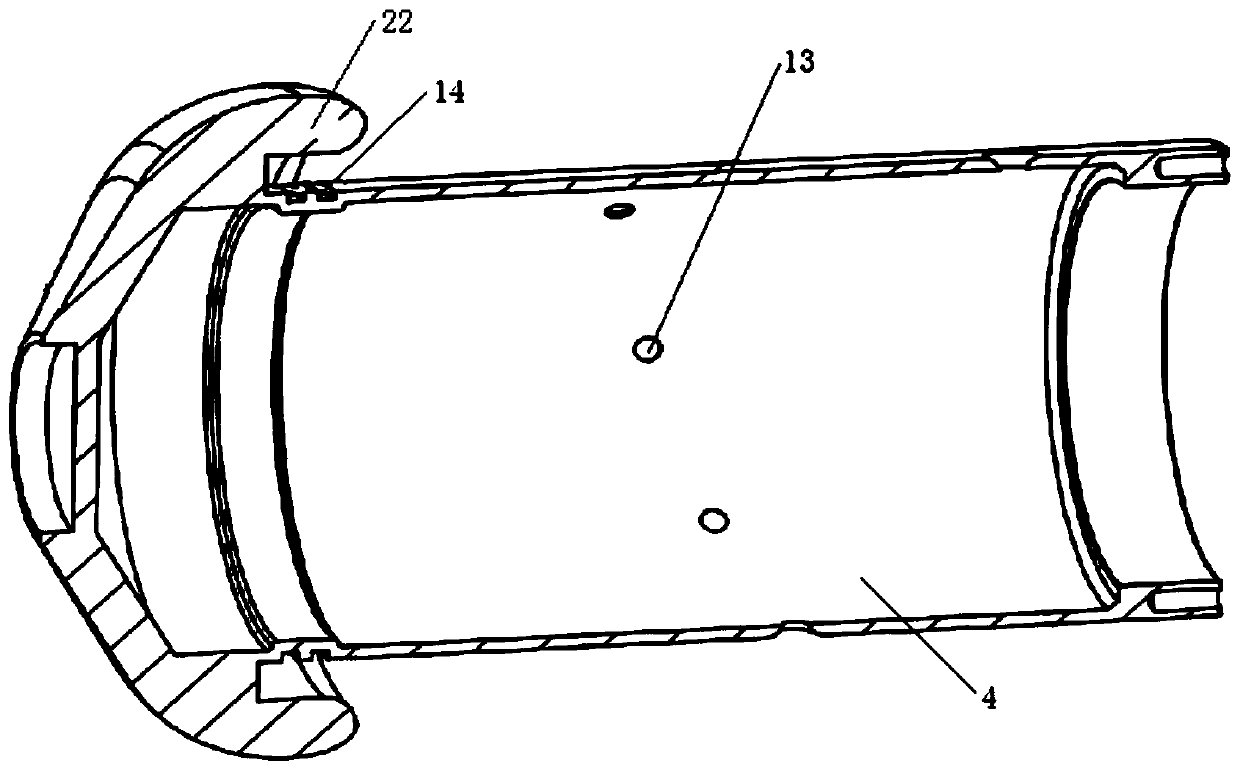

[0036] Such as figure 1 with figure 2 , A high-voltage pulse output device, comprising an outer cylindrical tube coaxially sleeved from the outside to the inside, an insulating support tube 3 and an inner cylindrical tube 4.

[0037] The outer cylinder includes a first outer cylinder 1 and a second outer cylinder 2 that are connected back and forth by a first flange 5, where the first outer cylinder 1 and the second outer cylinder 2 can be connected by an external flange It is also possible to directly process the first outer cylindrical tube 1 and the second outer cylindrical tube 2 into tube tubes with flanges at the joints, and then fix the connection by multiple sets of screws. The front end of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com