Spindle unit of bearing detecting device

A bearing testing and spindle technology, applied in mechanical bearing testing, bearings, shafts and bearings, etc., can solve problems such as decreased accuracy, rear bearing wear, easy oil leakage, etc., to reduce testing costs, prolong life, and expand the scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation of the present invention will be described below in conjunction with the accompanying drawings.

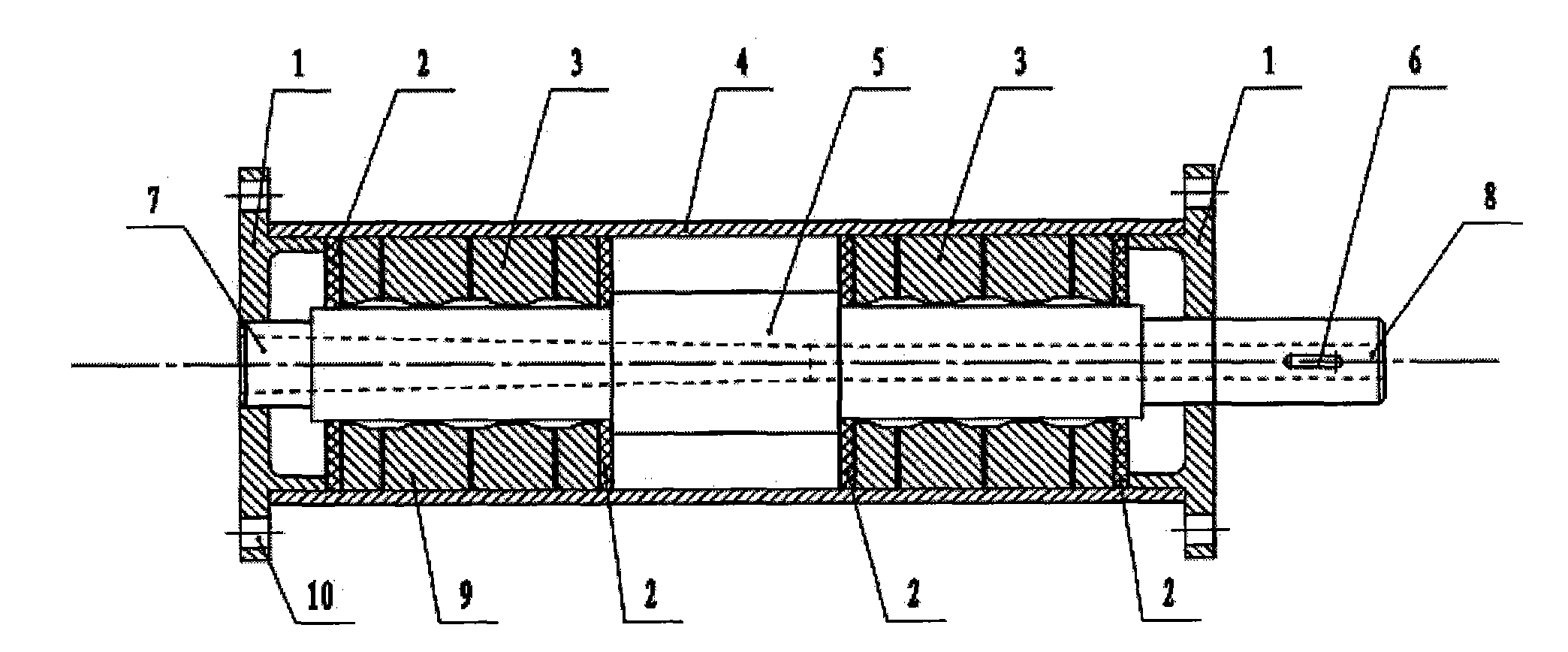

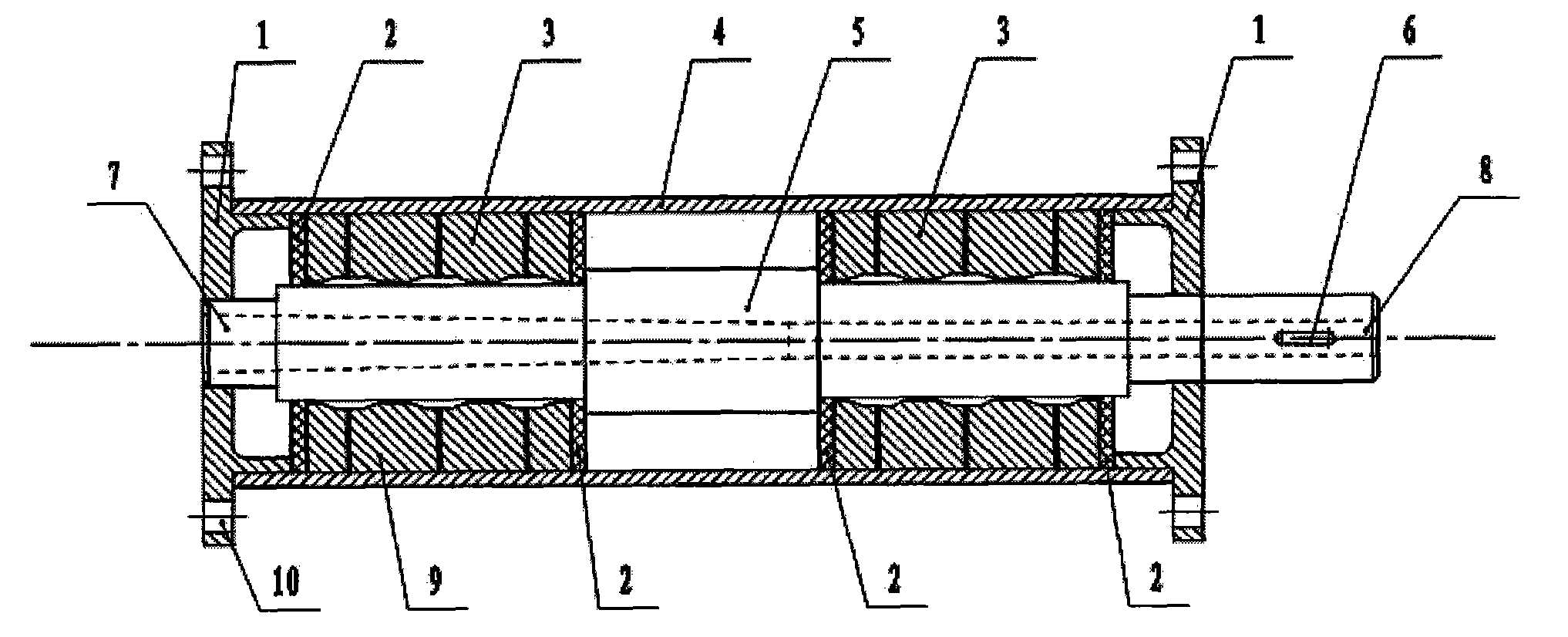

[0009] As shown in Figure 1, the main shaft unit of the bearing detection device includes a main shaft 5, two bearings 3 supporting the main shaft, and four sealing rings respectively located on both sides of the two bearings, one of which is equipped with two bearings and four sealing rings A sleeve 4 and two end caps 1 located at both ends of the sleeve. The two bearings 3 are two hydrostatic bearings; the center of one end of the main shaft 5 has a Morse taper hole 7 for installing a special mandrel for testing; the center of the rest of the main shaft has a central hole 8 for a special mandrel for unloading testing ; The other end of the main shaft protrudes from the end cover 1 and has a keyway 6 connected to the driving device; the end 1 is fixedly connected to the end of the sleeve 4 through the screw hole 10 on which the screw passes.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com