Clutch and compressor comprising same

A clutch and compressor technology, applied in clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problems of noise, vibration, attenuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, a clutch according to the present invention and a compressor including the clutch according to the present invention will be described in detail with reference to the accompanying drawings.

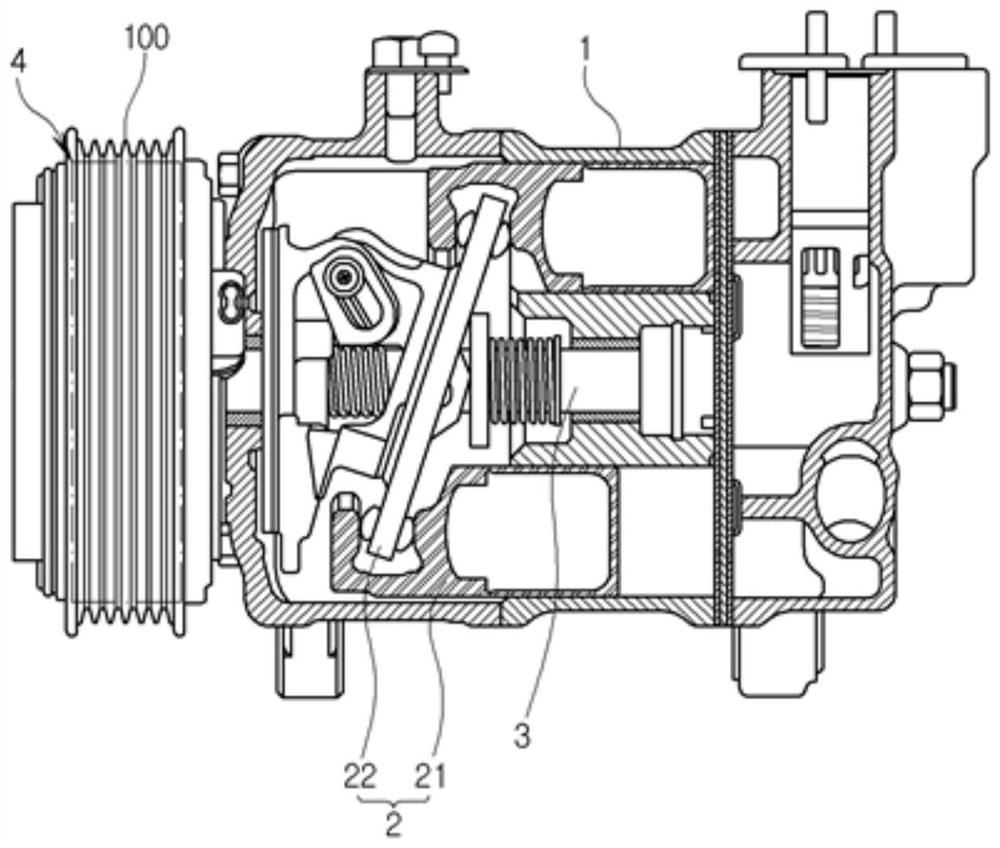

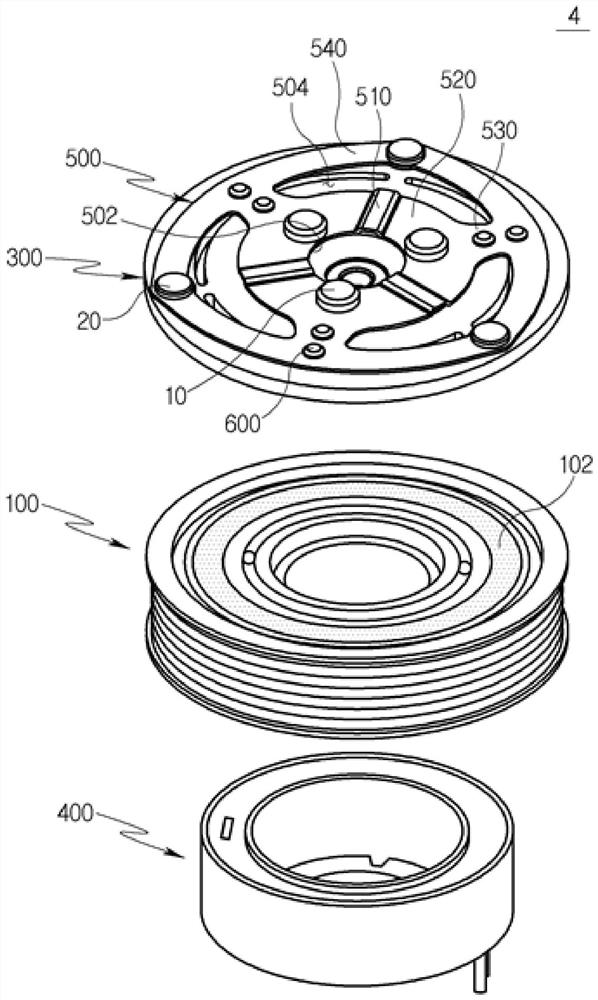

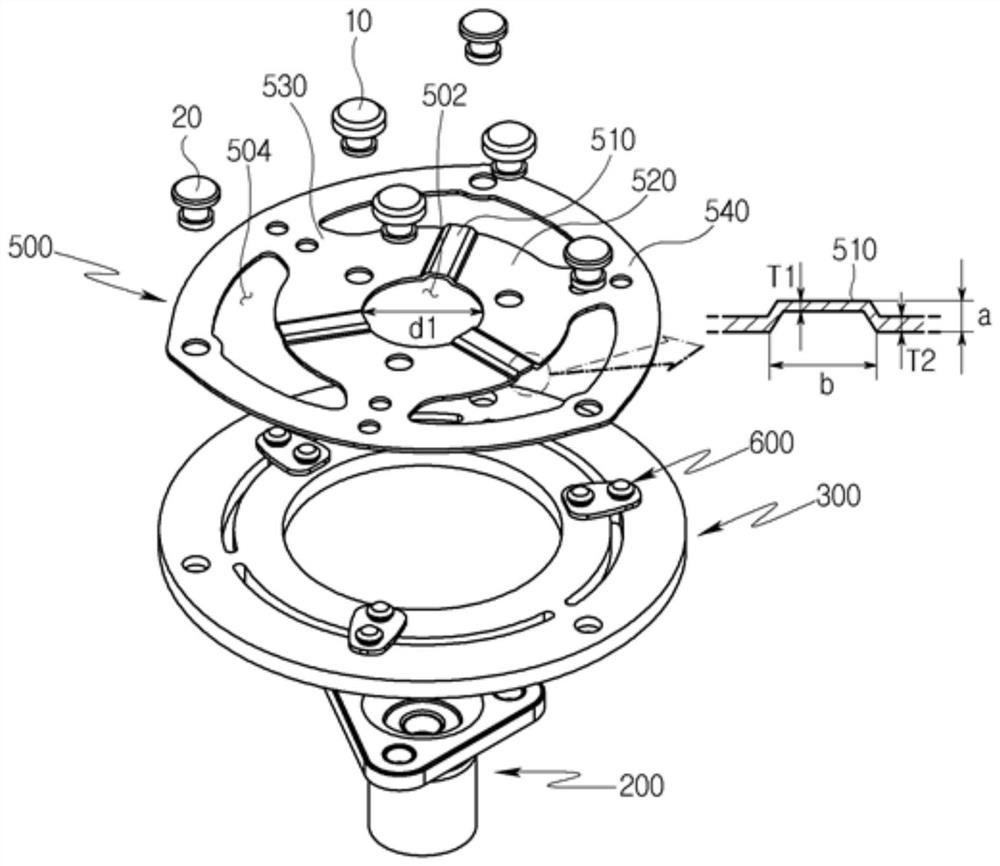

[0056] figure 1 is a sectional view showing a compressor including a clutch, figure 2 is an exploded perspective view showing the clutch according to the first embodiment of the present invention, and image 3 is showing figure 2 An exploded perspective view of the disc hub assembly.

[0057] A clutch according to a first embodiment of the present invention will be described with reference to the drawings.

[0058] Refer to the attached Figure 1 to Figure 3 , the clutch according to the first embodiment of the present invention minimizes the generation of vibration by increasing the rigidity to prevent the vibration transmitted in the shaft direction of the clutch due to the vibration caused by the compressor provided in the vehicle during operation. The result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com