Dynamic vibration absorber for industrial pipeline

A technology for dynamic vibration absorbers and industrial pipelines, applied in pipeline supports, non-rotational vibration suppression, pipes/pipe joints/fittings, etc., can solve the problems of vibration absorption effect, narrow vibration absorption frequency of vibration absorbers, and impact on pipelines, etc., to improve vibration The effect of widening the vibration absorption frequency and suppressing the pipeline vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

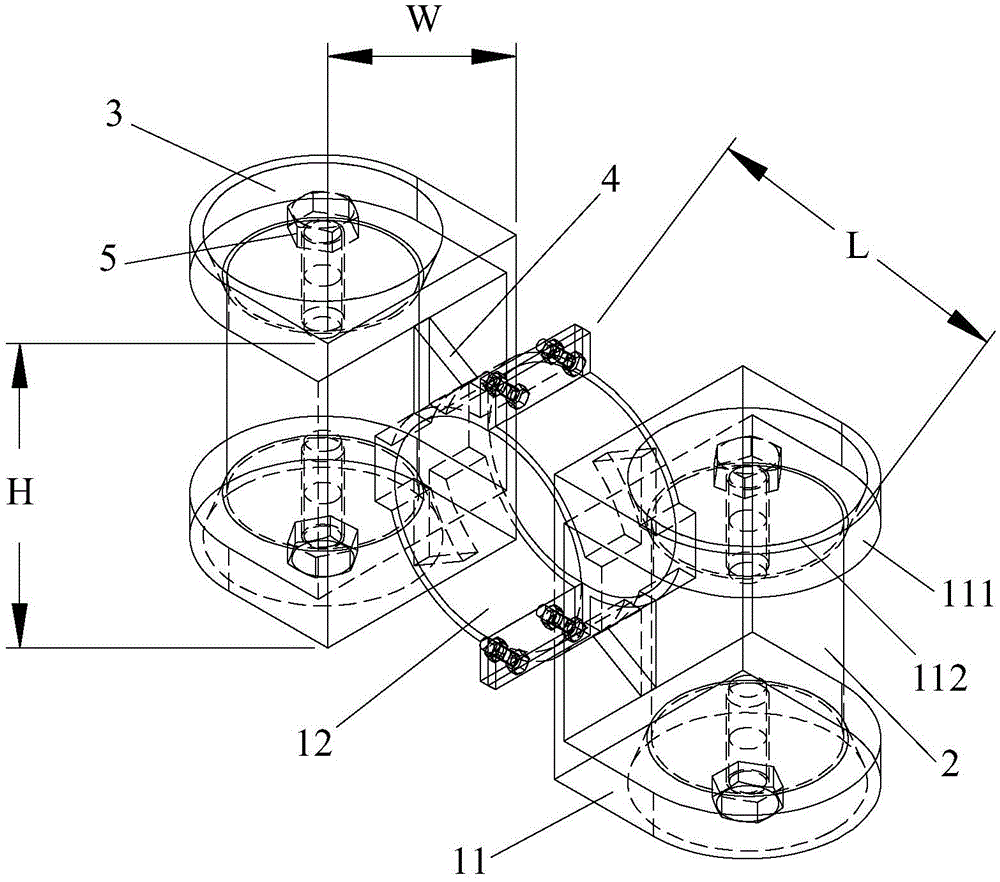

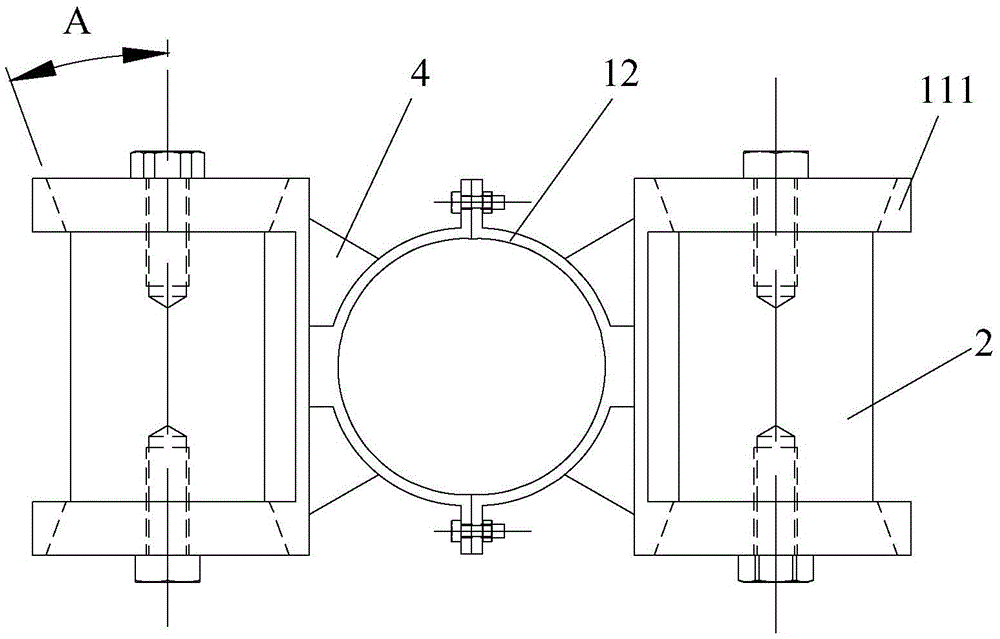

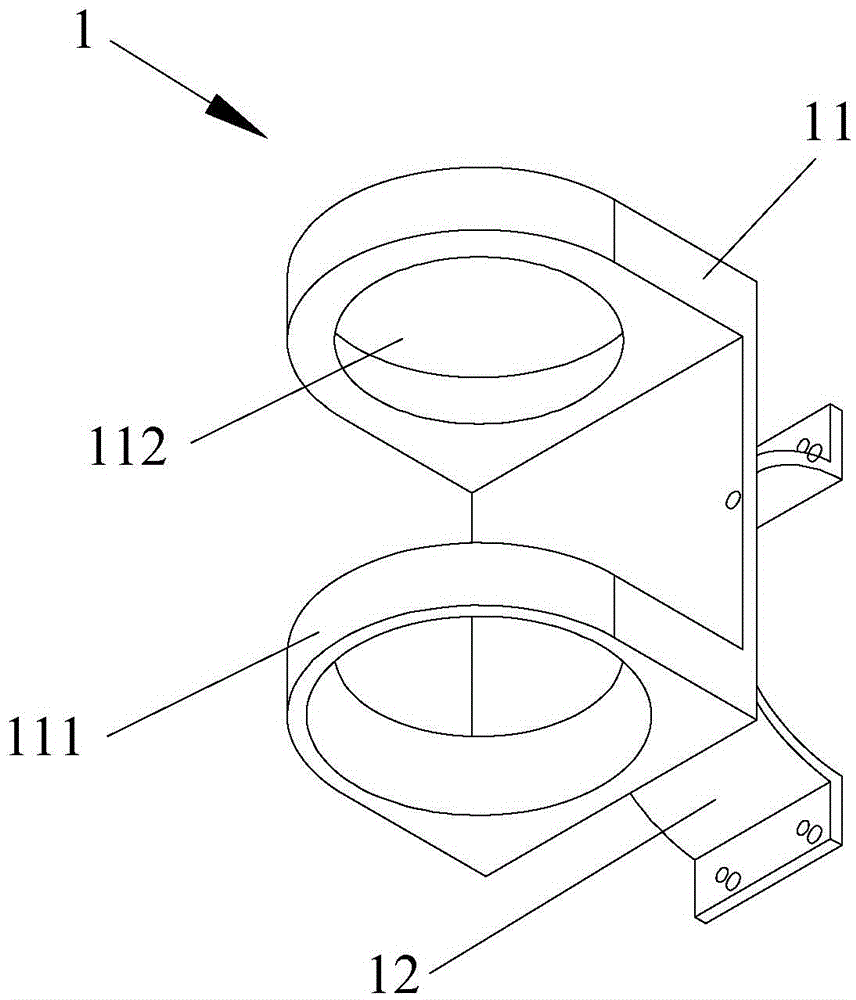

[0042] Such as figure 1 As shown, the industrial pipeline dynamic vibration absorber proposed by the present invention includes: two brackets 1, which can be symmetrically engaged on the outer wall of the pipeline (the pipeline is not shown in the figure), and can be docked and fixed between the two brackets 1; two mass blocks 2 , the two mass blocks 2 are detachably installed on the two brackets 1 respectively. In a specific embodiment, the size of the bracket 1 can be: the length L is 160mm, the height H is 148mm, and the width W is 93mm. The material for making the bracket 1 can be selected from steel, such as No. 45 steel; the mass block 2 can be By replacing according to actual needs, the mass block 2 with suitable weight and size can be selected. Through the finite element simulation analysis of the industrial pipeline dynamic vibration absorber of the present invention, it can be seen that the actual maximum vibration position of the pipeline is at the top part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com