Experimental method for measuring critical speed influencing factors for steam turbine rotor

A steam turbine rotor and critical speed technology, which is applied in measuring devices, linear/angular velocity measurement, velocity/acceleration/impact measurement, etc., can solve problems such as equipment damage, unit shutdown, rubbing, etc., and achieve far-reaching theoretical significance and engineering practical value , Reduce the effect of abnormal vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The patent of the present invention will be described in detail below with reference to the embodiments shown in the accompanying drawings.

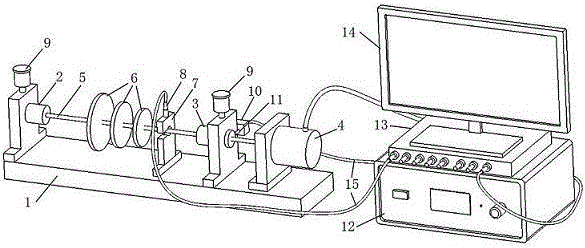

[0016] The symbols in the figure are: 1. Chassis 2. First sliding bearing 3. Second sliding bearing 4. Drag motor 5. Steam turbine rotor simulation main shaft 6. Steam turbine rotor simulation wheel 7. Displacement sensor bracket 8. Displacement sensor 9. Oil Pot 10. Speed sensor bracket 11. Speed sensor 12. Speed governor 13. Vibration data analyzer 14. Computer and test software 15. Connecting wires

[0017] Its structure and composition are: chassis, first sliding bearing, second sliding bearing, drag motor, steam turbine rotor simulation main shaft, steam turbine rotor simulation wheel, displacement sensor bracket, displacement sensor, oil pot, speed sensor bracket, speed sensor, Speed governor, vibration data analyzer, computer and test software, connecting wire. Install the first sliding bearing (2), the second slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com