Gas dynamic pressure bearing and manufacturing method thereof, and mechanical equipment

A technology of gas dynamic pressure bearing and manufacturing method, applied in the field of bearings, can solve the problems of reduced design flexibility, increased design difficulty, reduced bearing design flexibility, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

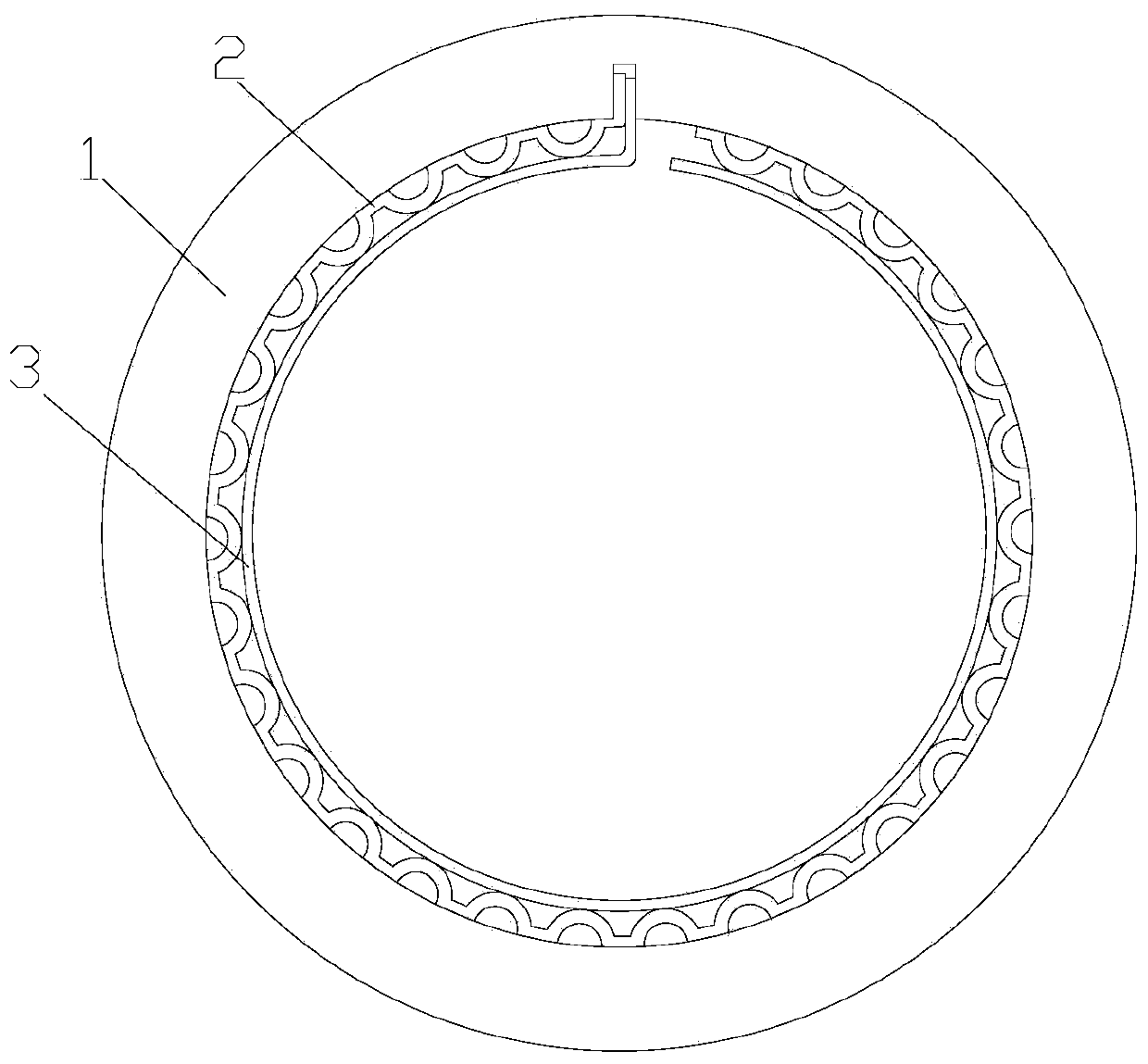

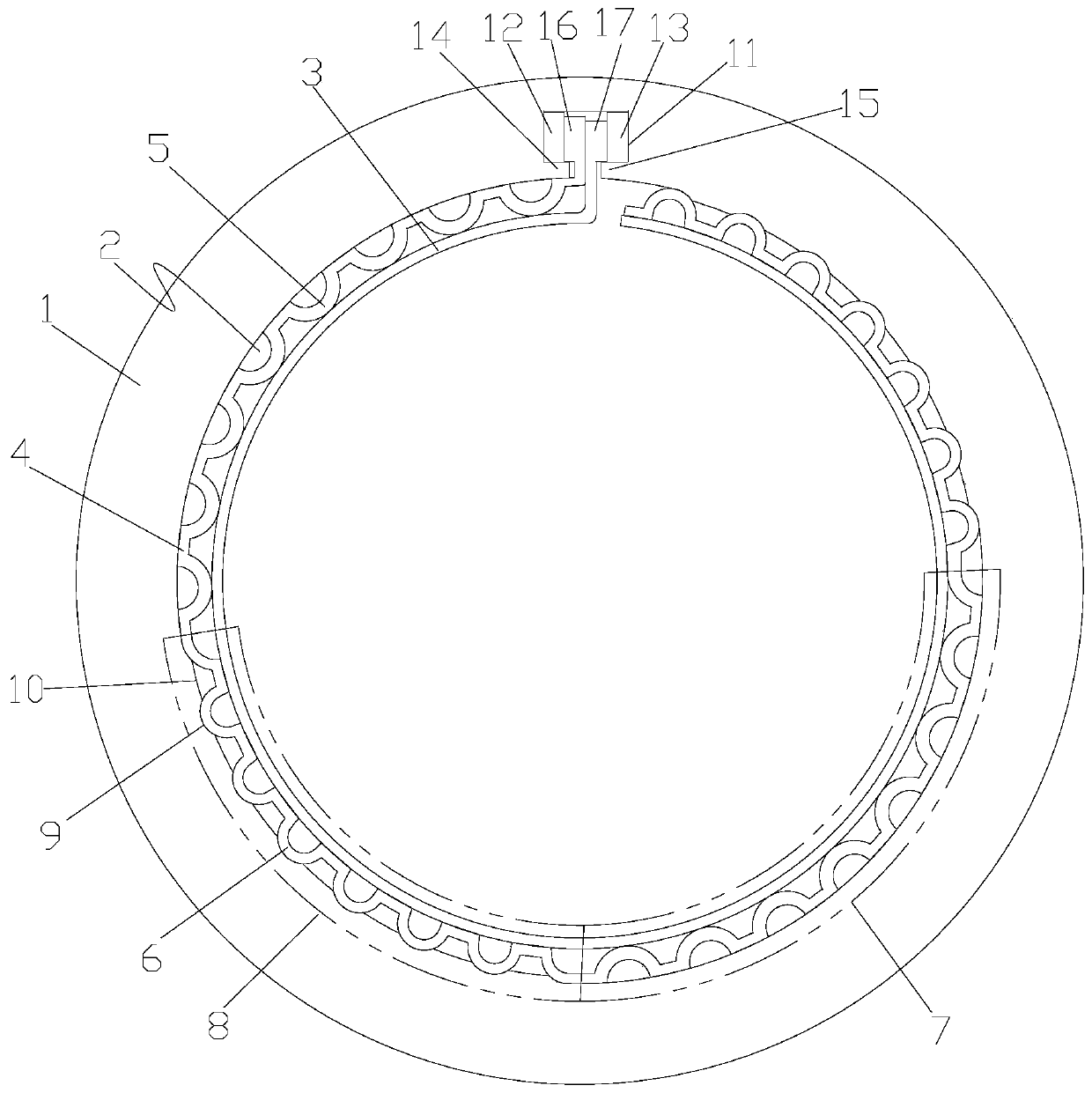

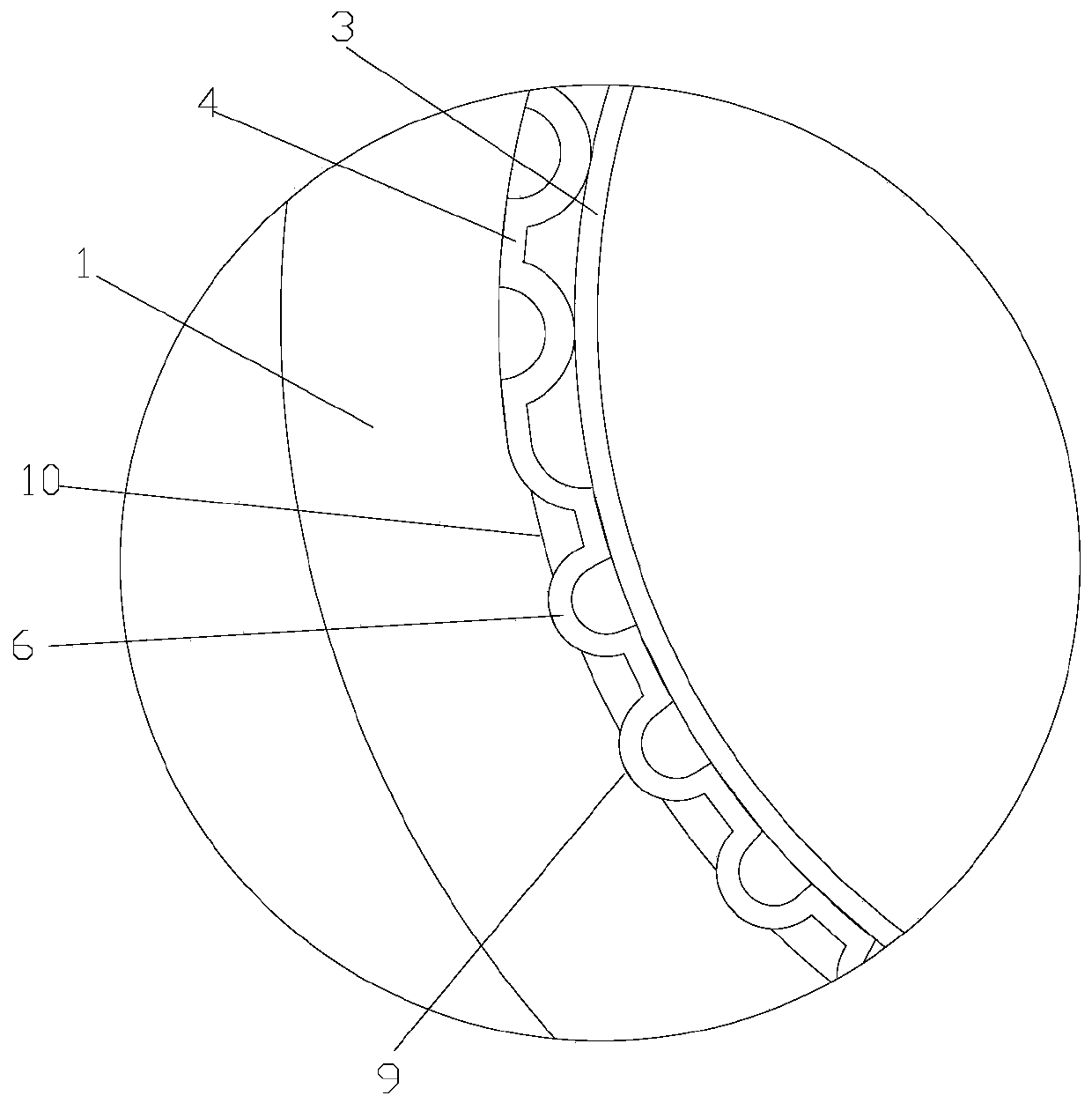

[0064] see in conjunction Figure 2 to Figure 6 As shown, according to the embodiment of the application, the gas dynamic pressure bearing includes a bearing seat 1, an arch foil 2 and a top foil 3, the arch foil 2 is located between the bearing seat 1 and the top foil 3, and the arch foil 2 includes a connecting section 4 and an arch foil Shaped segment, connecting segment 4 and arched segment are arranged in sequence along the circumference of the arch foil 2, the connecting segment 4 is connected between the roots of the arched segment, and the arched segment includes a first arched segment 5 and a second arched segment 6 , the first arched segment 5 protrudes toward the outer peripheral wall of the top foil 3 , and the second arched segment 6 protrudes toward the inner peripheral wall of the bearing seat 1 .

[0065] In the design stage of the aerodynamic bearing, a variety of bearings with different support stiffness and damping can be designed by using arch foils of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com