Motor rotor and magnetic suspension motor

A motor rotor and shaft technology, applied in the field of motor rotor and magnetic levitation motor, can solve the problems of large sheath temperature rise, poor suspension accuracy, rotor eccentricity, etc., and achieve the effects of reducing temperature rise, improving accuracy, and reducing the degree of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

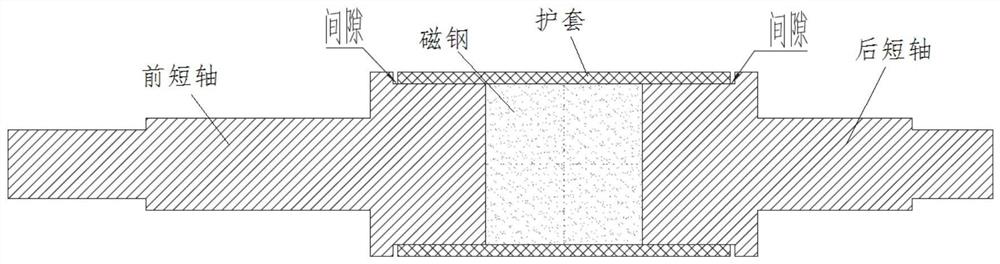

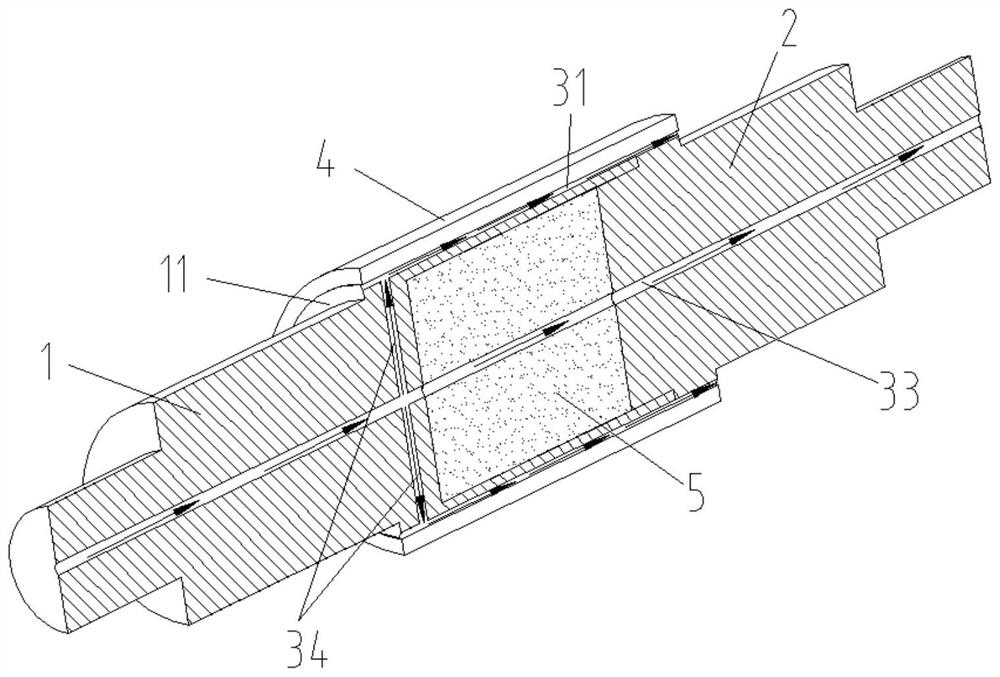

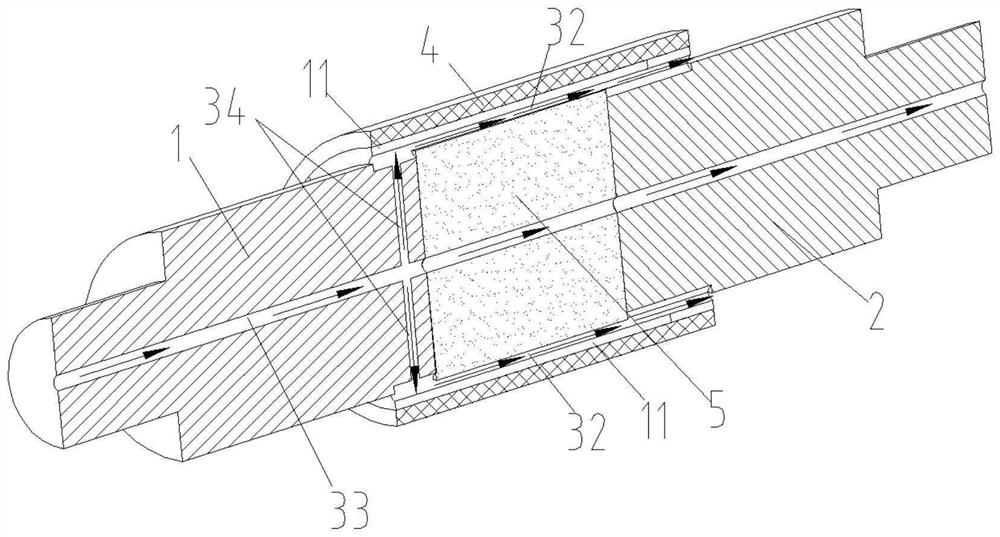

[0036] see in conjunction Figure 2 to Figure 12 As shown, according to an embodiment of the present invention, a motor rotor is provided, including a rotating shaft, the rotating shaft has a hollow cylinder section, the outer peripheral side of the hollow cylinder section is fitted with a sheath 4 in an interference fit, and the hollow cylinder section A magnetic steel 5 is interference-connected on the inner side of the cylinder wall of the hollow cylinder section, and a first cooling pipe 31 is provided between the sheath 4 and the cylinder wall of the hollow cylinder section. In this technical solution, the cooling medium (such as cooling oil) is guided to the jacket 4 by arranging the first cooling pipeline 31 between the jacket 4 and the hollow open-closed cylinder wall. The cooling of the sheath 4 effectively reduces the temperature rise of the sheath 4, thereby reducing the deformation of the sheath 4, rotor eccentricity, and vibration, and when it is applied to a magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com