power tool

A power tool and working head technology, applied in the field of hand-held power tools, can solve the problems of large operating force and difficulty of the wrench

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

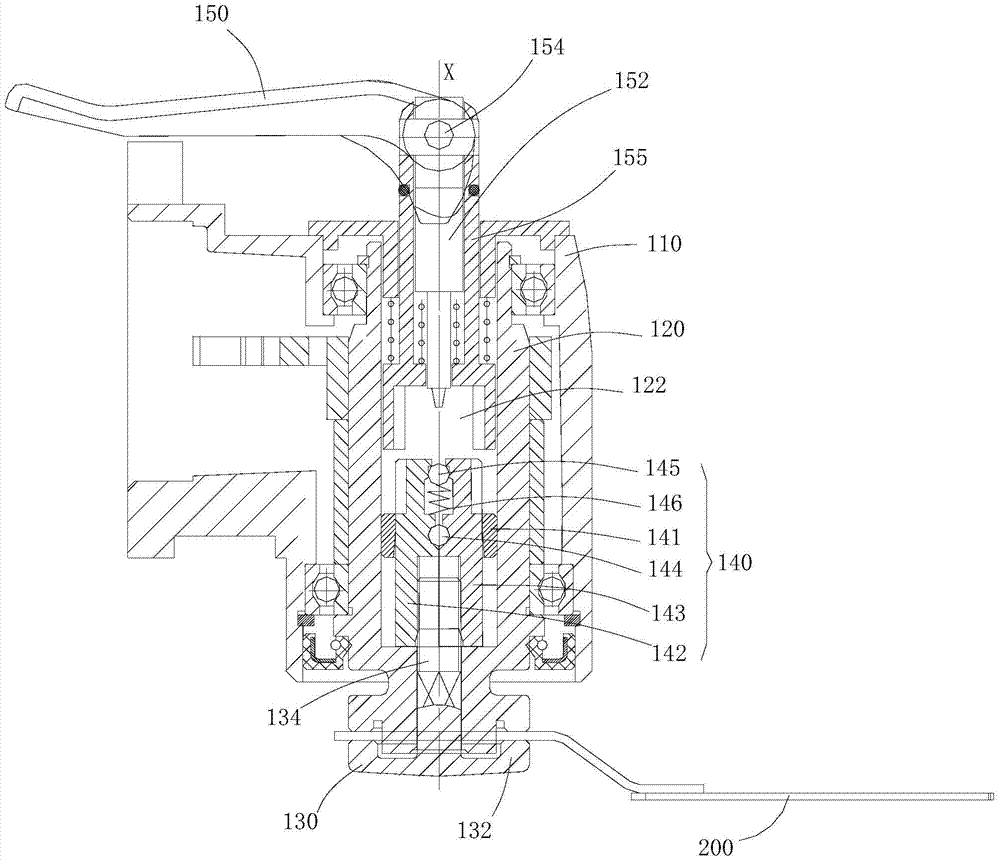

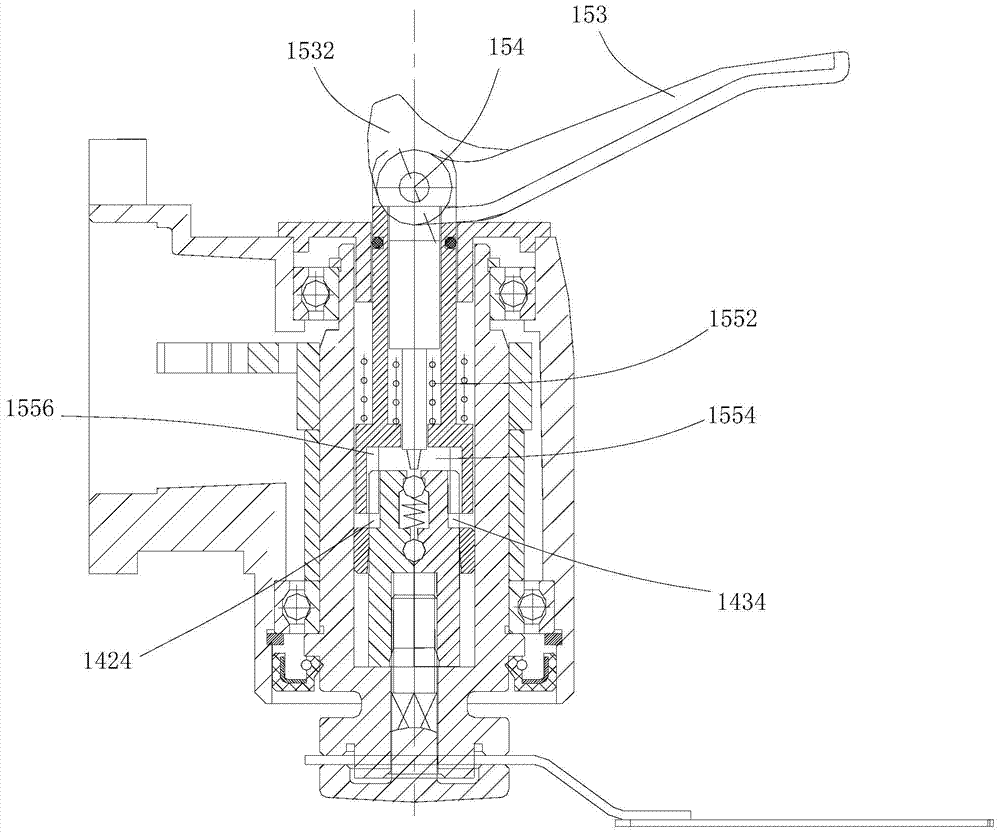

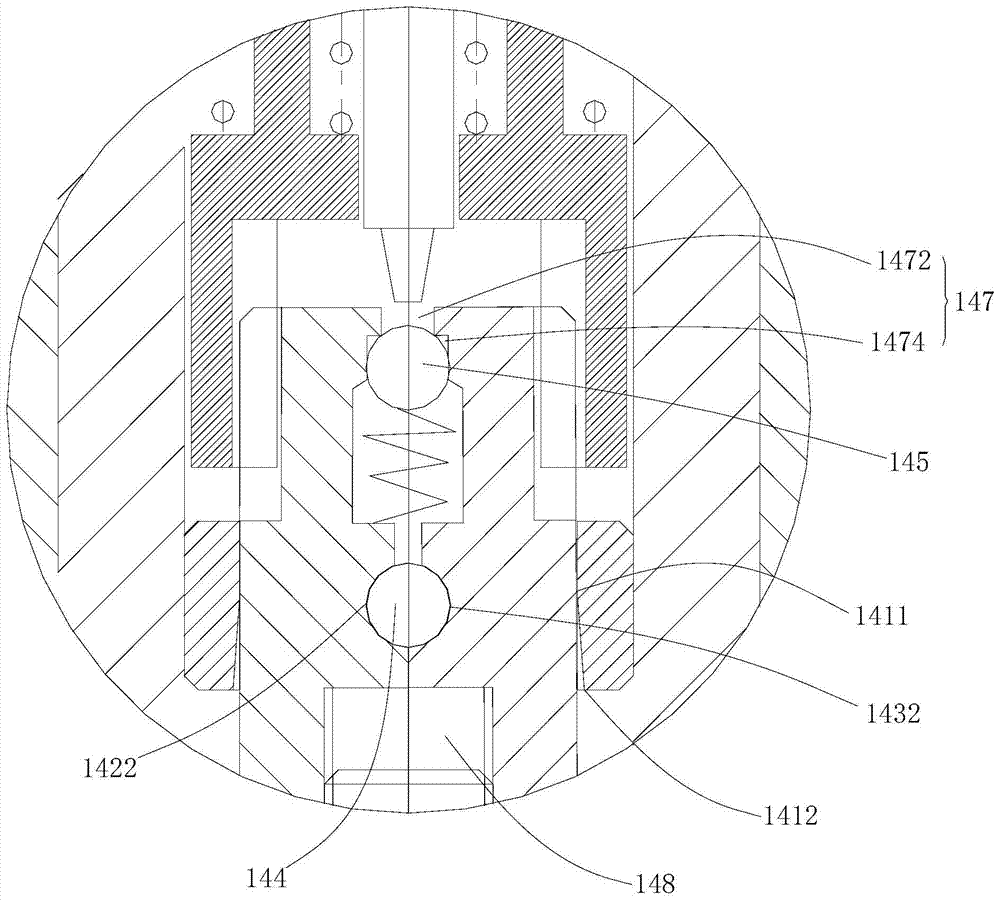

[0051] Please refer to Figure 1 to Figure 9, the power tool of Embodiment 1, which is described here by taking a multifunctional machine as an example, includes a housing 110, an output shaft 120 disposed in the housing 110 and one end extending out of the housing 110, a fixing member 130, and an output shaft 120 disposed on the output shaft 120. The locking assembly 140 and the driving mechanism 150 in the. The output shaft 120 is used to drive the working head 200 to work, wherein the output shaft 120 can swing around its own axis X, which is well known to those skilled in the art and is not the focus of this embodiment, so it will not be described again. The fixing part 130 is used to press the working head 200 onto the free end of the output shaft 120 . The locking assembly 140 is used to lock the fixing member 130 to fix the working head 200 on the output shaft 120 . The driving mechanism 150 is used to drive the locking assembly 140 to move to achieve or release the l...

Embodiment 2

[0076] The power tool of the second embodiment of the present invention is similar in structure to the first embodiment, the only difference is the locking component, so only the locking component will be described below.

[0077] Please refer to Figure 10 and Figure 11 , the locking assembly 740 of the power tool in the second embodiment includes a sleeve 741, a first clamping piece 742, and a second clamping piece 743, and the rotation between the first clamping piece 742 and the second clamping piece 743 The shaft 744 , the locking piece 745 , and the first elastic piece 746 .

[0078] In this embodiment, the locking member 745 is a cross, including a blocking portion 7452 abutting against the first clamping component 742 and the second clamping component 743 and a pressing portion 7454 extending out of the channel 747 . Certainly, the pressing portion 7454 may not protrude from the channel 747 , and when the locking member 745 needs to be moved, the push rod can be ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com