Quick coupling for fluid loading and unloading

A fluid and fast technology, applied in liquid distribution, transportation or transfer devices, packaging, distribution devices, etc., can solve problems such as inoperability, increased operating force, and inability to achieve normal transportation, reducing media loss, improving safety, The effect of reducing the actuation force of the handwheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described below according to the embodiments shown in the accompanying drawings.

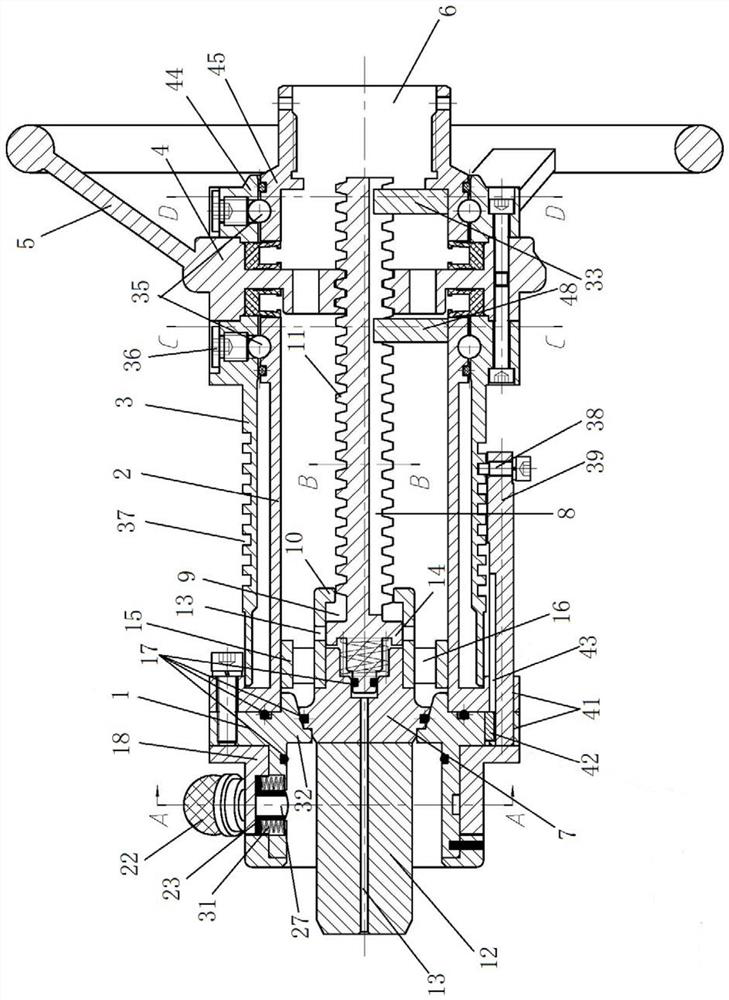

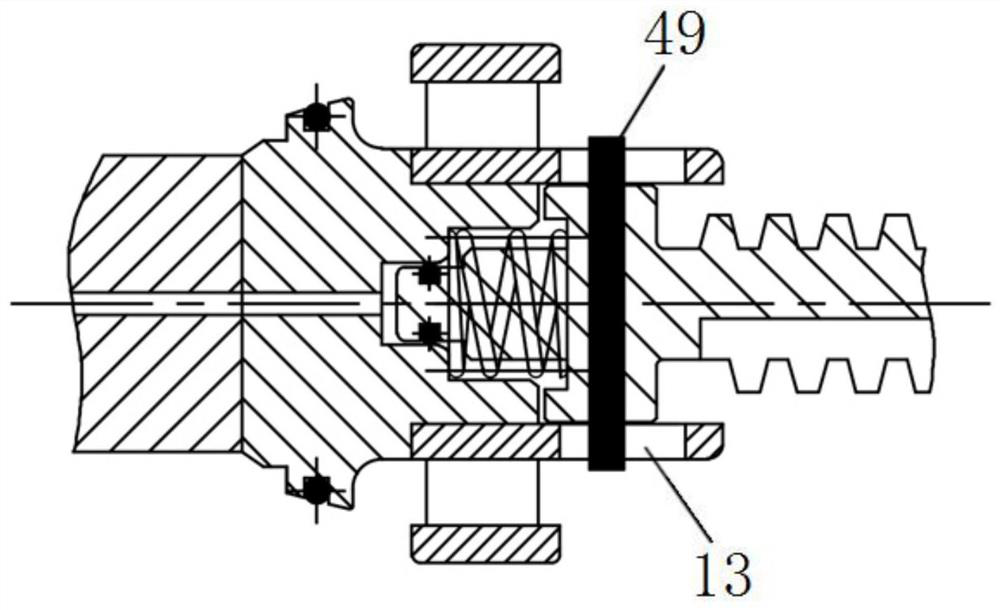

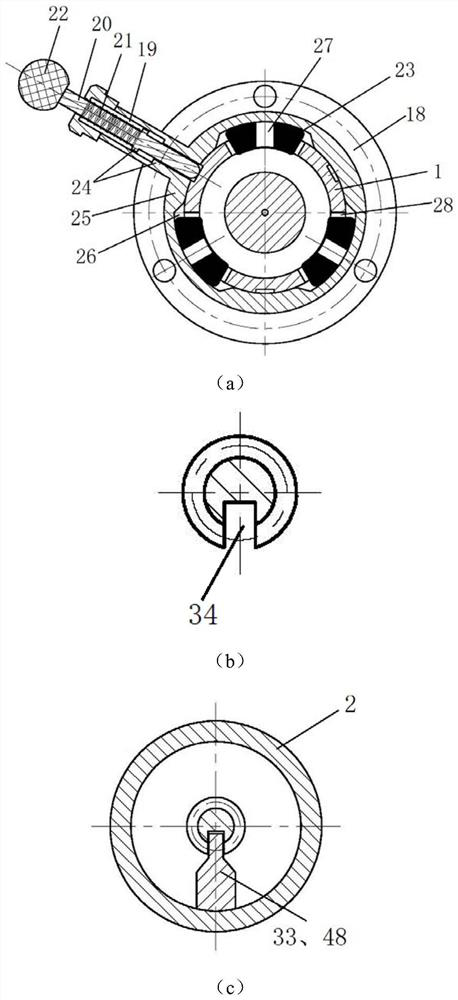

[0040] Such as figure 1 with 3 As shown, a quick connector for fluid loading and unloading in this embodiment includes a locking device, a double valve structure, a fixed inner ring 1, a guiding inner ring 2, an outer ring 3, a nut flange 4, a hand wheel 5 and a mounting end 6. The double valve structure is located in the guide inner ring 2, including a sliding main valve core 7 and a screw auxiliary valve core 8, both of which can translate axially along the joint. Wherein, the rear end of the sliding main valve core 7 is provided with a cavity 9, and the front end of the screw auxiliary valve core 8 is embedded in the cavity 9, and can slide within a certain range in the cavity 9. A limiting block 10 is provided at the end of the cavity 9 for limiting the sliding of the front end of the screw auxiliary valve core 8 . When the valve structure is opened a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com