Patents

Literature

106results about How to "Precise sowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Internet of Things method and system

The invention relates to an Internet of Things method and system. Through techniques, complex Internet of Things associated elements are systematically sorted; analysis is carried out from different dimensions; an application-level service referable Internet of Things system architecture model is set, the Internet of Things capability problems of good comprehensive perception, convenient access, reliable transmission, data value, intelligent processing, business closed loop, system guarantee, sustainable development and the like are solved, the fusion of a physical world and a digital world isbetter realized, and the wisdom of a human body is materialized and extended.

Owner:陕西爱尚物联科技有限公司

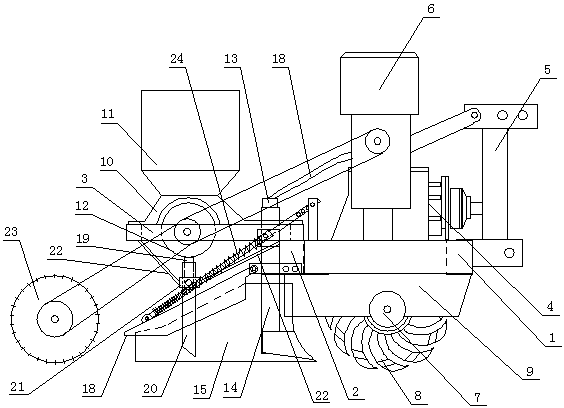

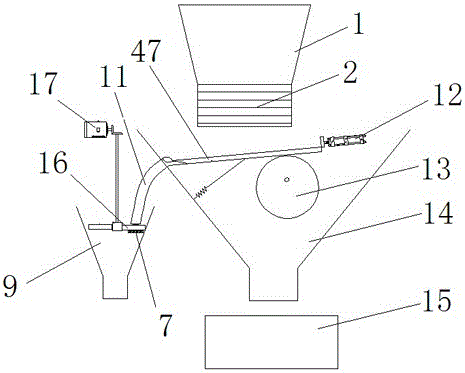

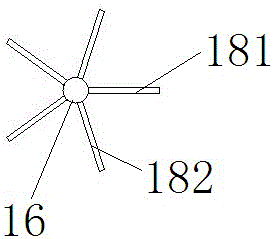

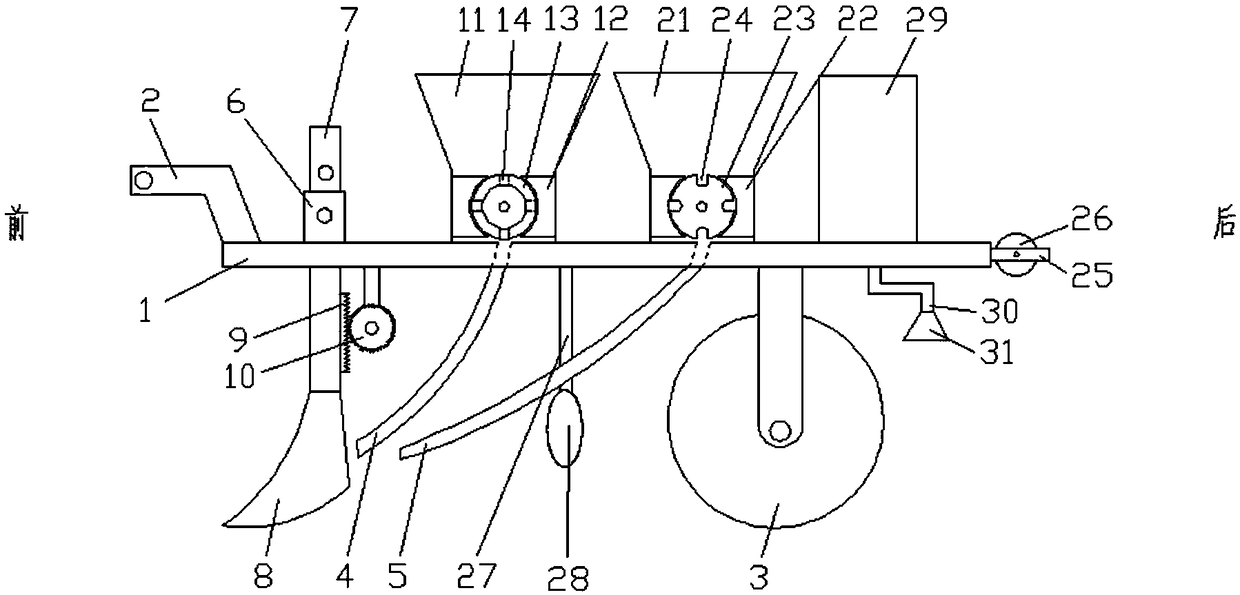

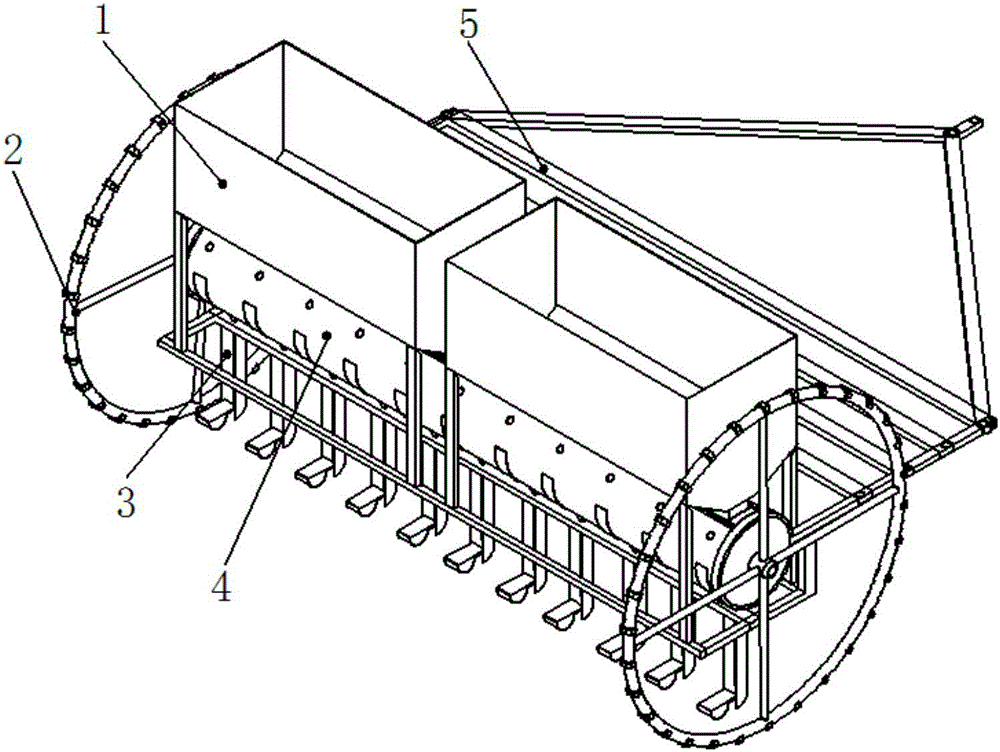

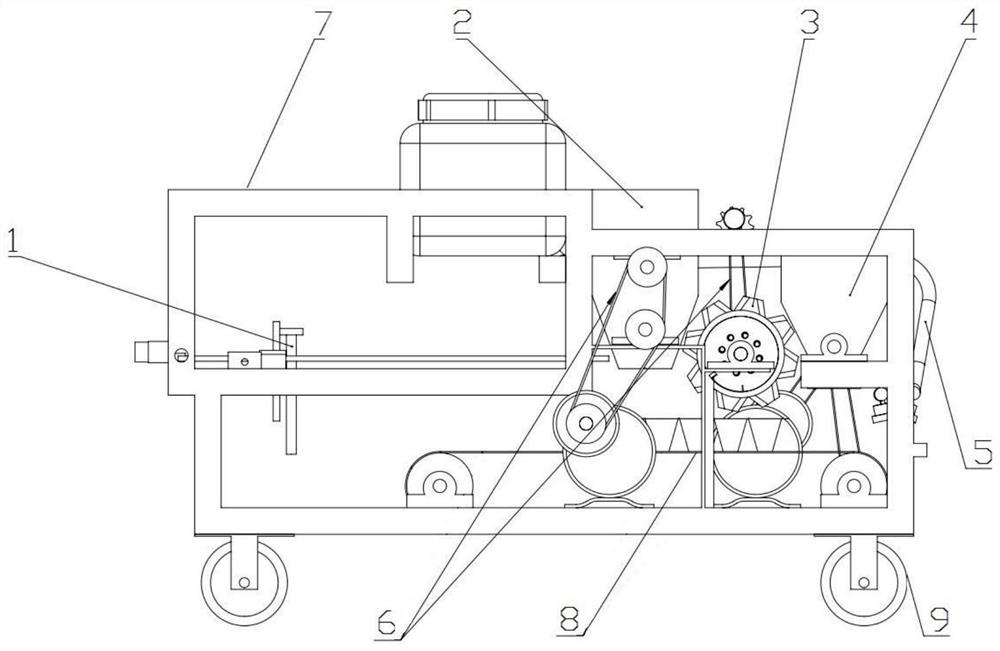

Rotary tillage, ridging, sowing and fertilizing all-in-one machine

InactiveCN104255099AAvoid destructionGuaranteed stabilitySpadesPloughsAgricultural engineeringTillage

The invention discloses a rotary tillage, ridging, sowing and fertilizing all-in-one machine. By adopting a rack structure which is composed of a front beam, a back beam and a square bracket, arranging a fertilizer box above a gearbox, and fusing ditching, ridging, fertilizing and sowing into an integral structure, fertilization and sowing are finished in the ditching and ridging process; the all-in-one machine is not only compact and flexible, but damage from gathered soil to a fertilizing part is also avoided in the ditching and ridging process as a fertilizing leg is located in the middle of a ditcher, and stability of the soil at the fertilizing part is ensured; meanwhile, a sowing pipe is located between the fertilizing leg and the ditcher in the transverse direction, is located between side wing plates of the ditcher in the lengthways direction and is located below a soil covering plate in the vertical direction, to be short, is located at the place where soil is gathered and shaped, so that the soil is basically in a steady structure at the place, and stability of the position of a seed sown at the place can be guaranteed efficiently, row distance, plant distance and planting depth can be controlled and mastered conveniently, and precise sowing is realized.

Owner:南阳市金海洋农机有限公司

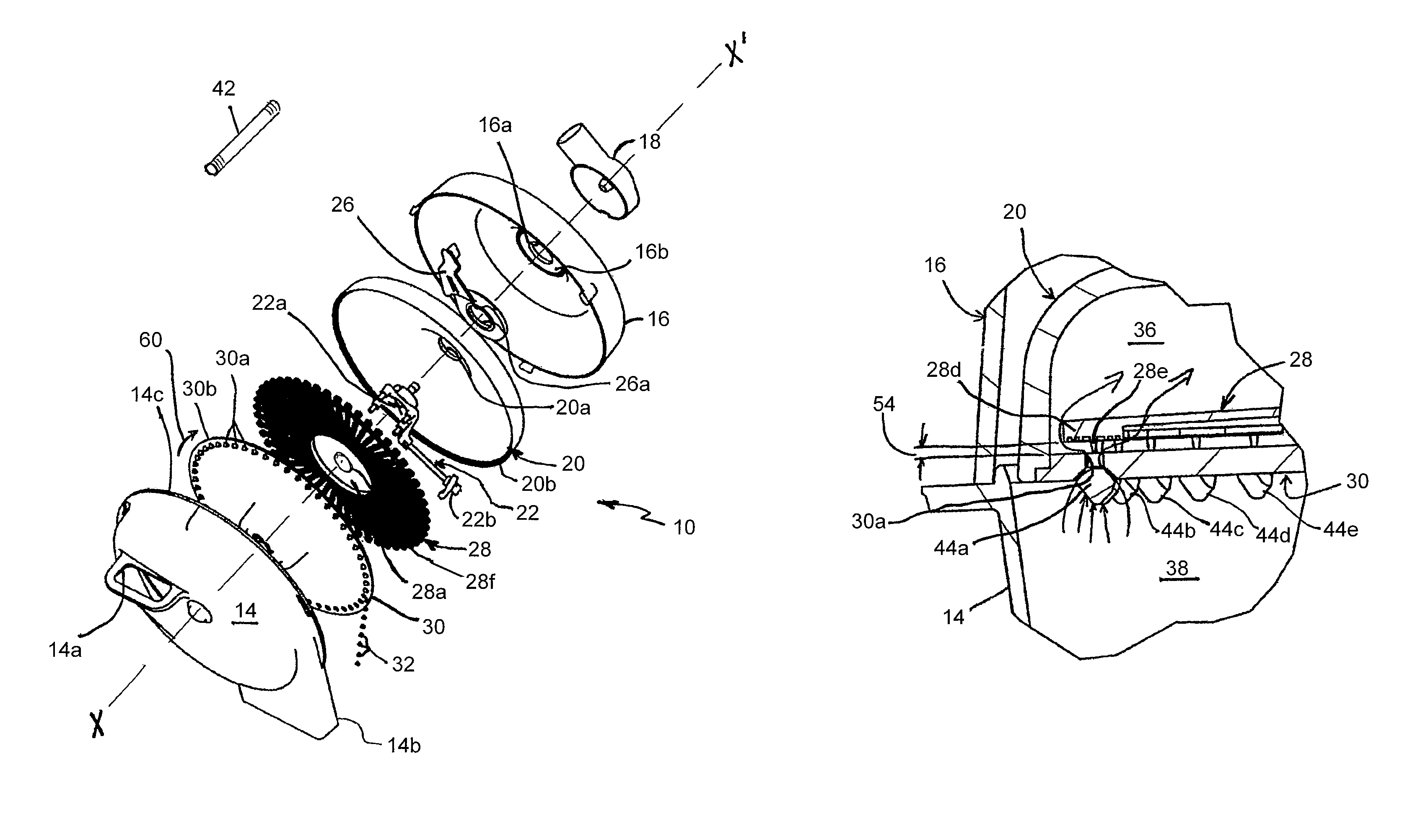

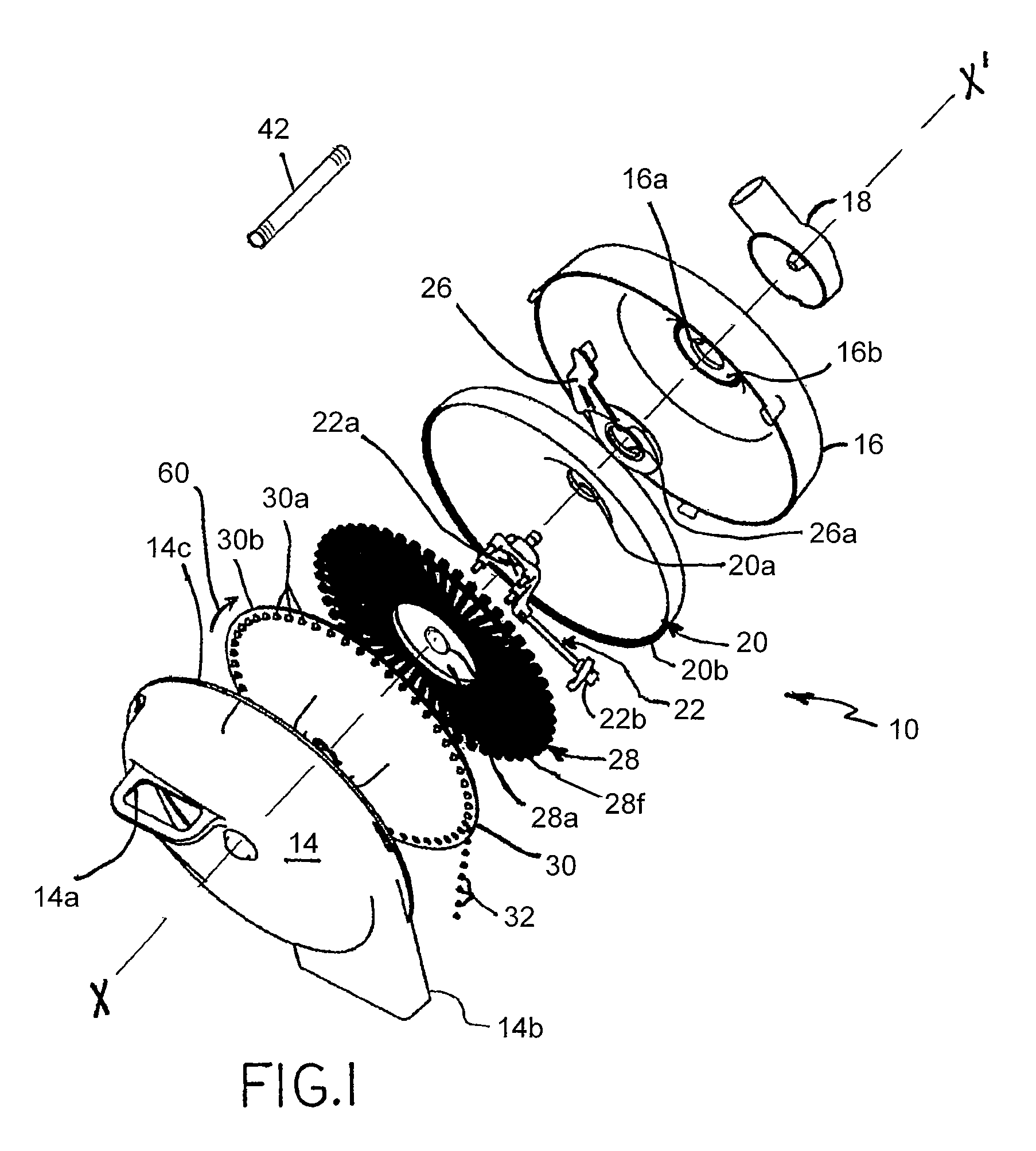

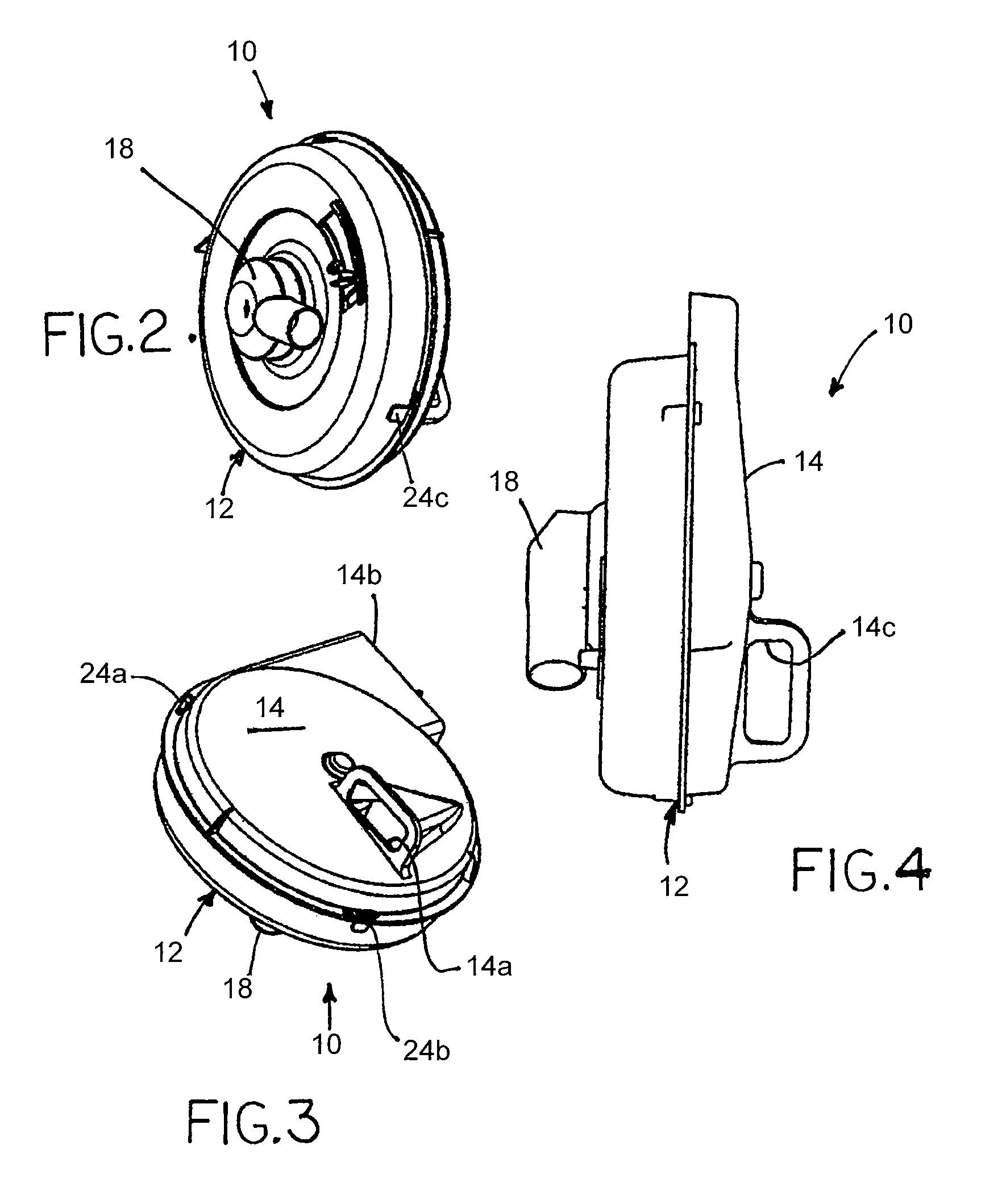

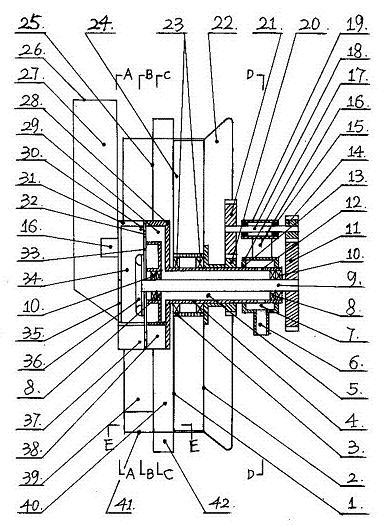

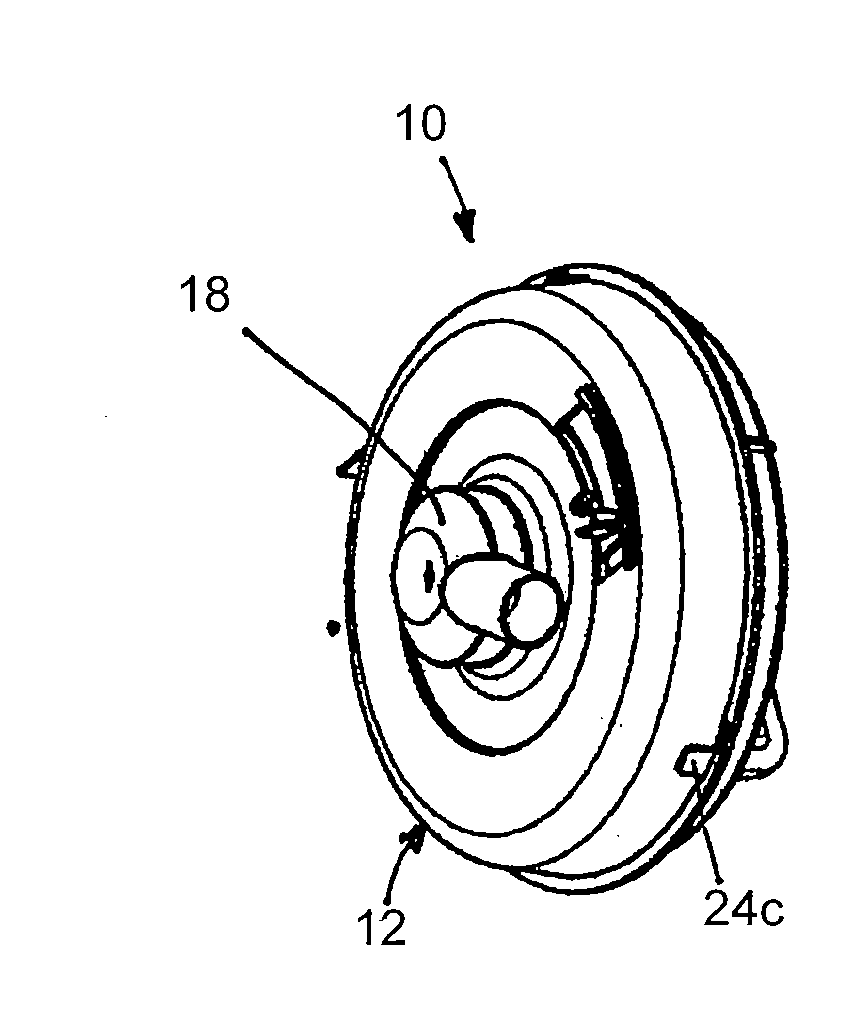

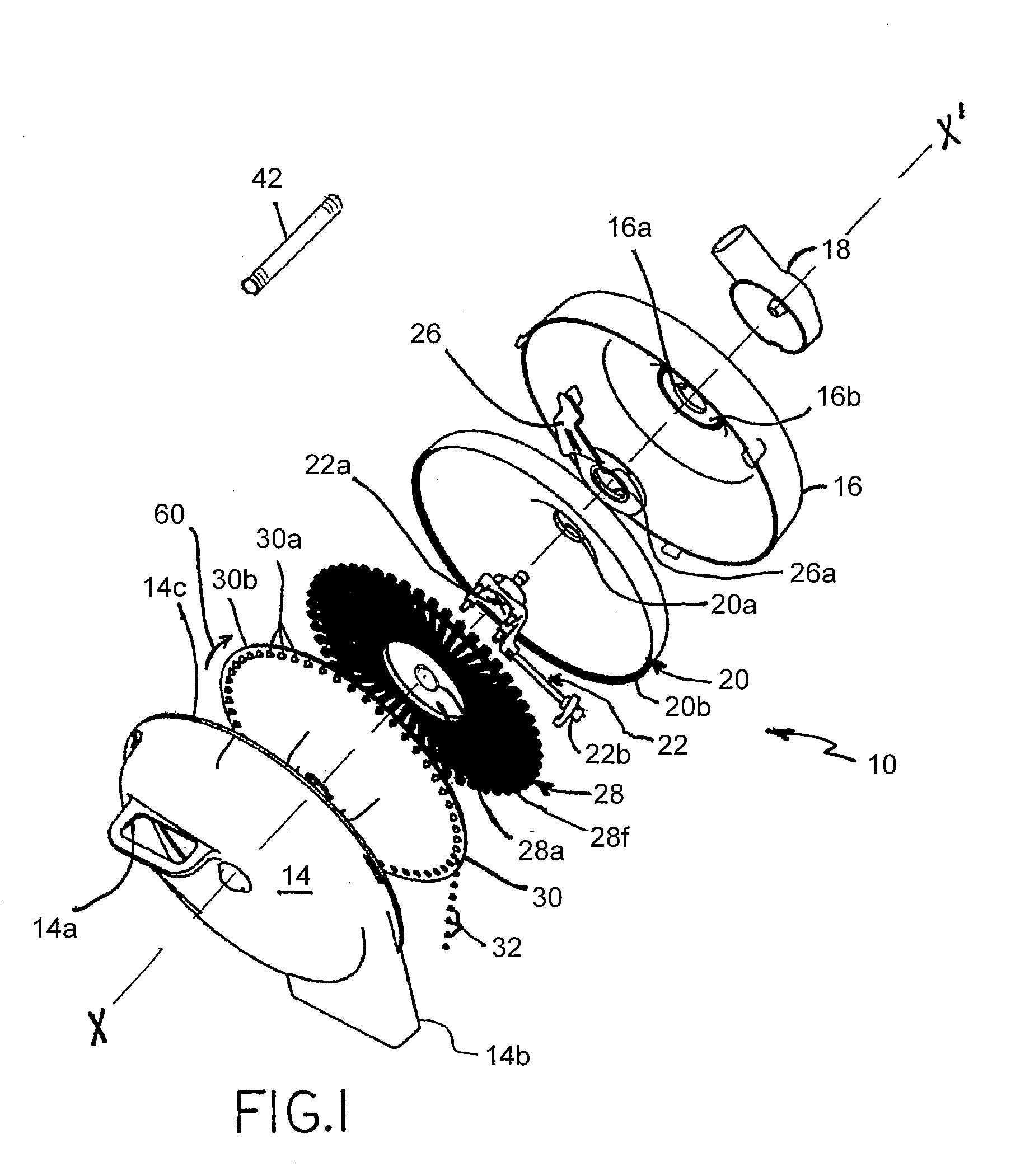

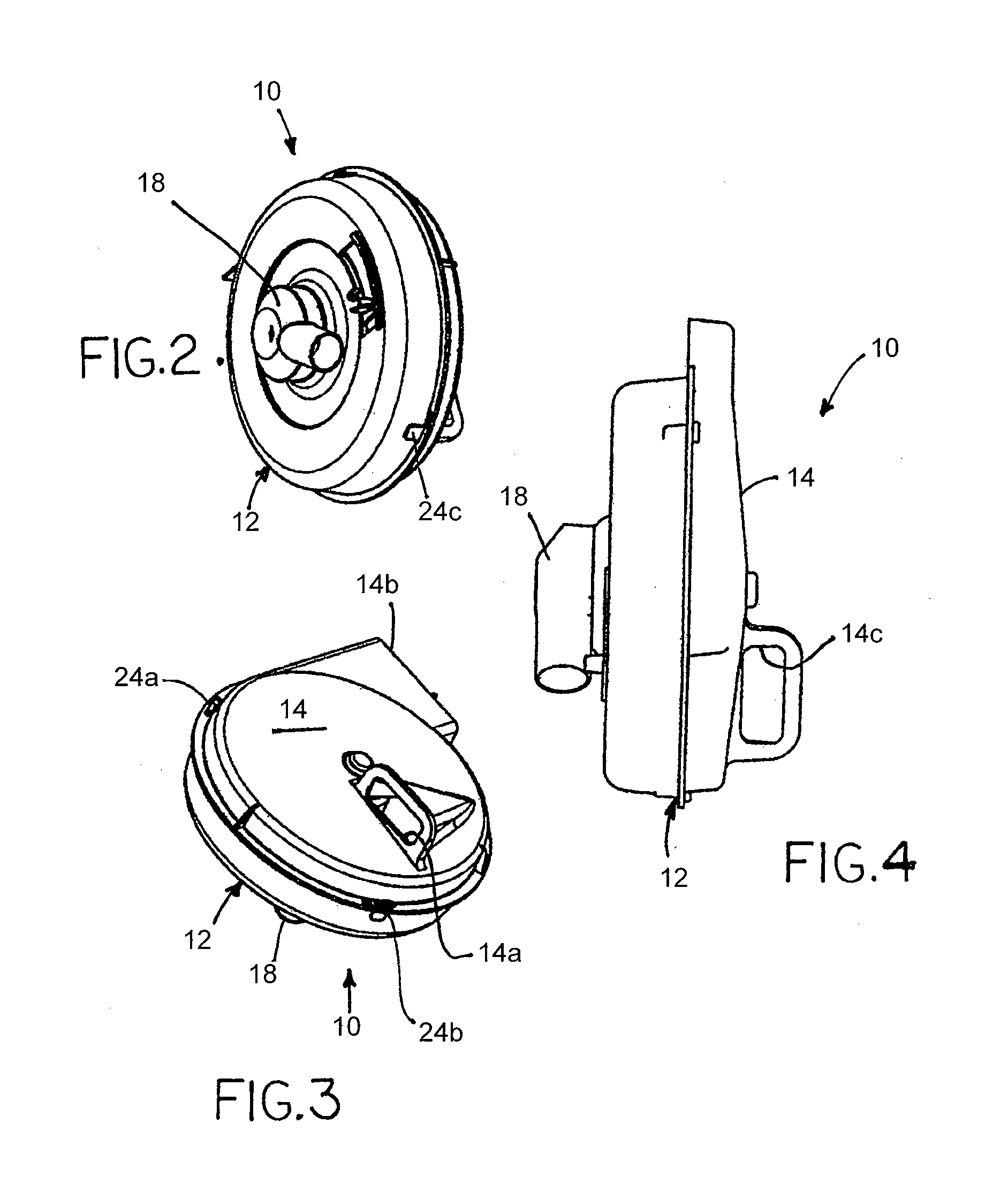

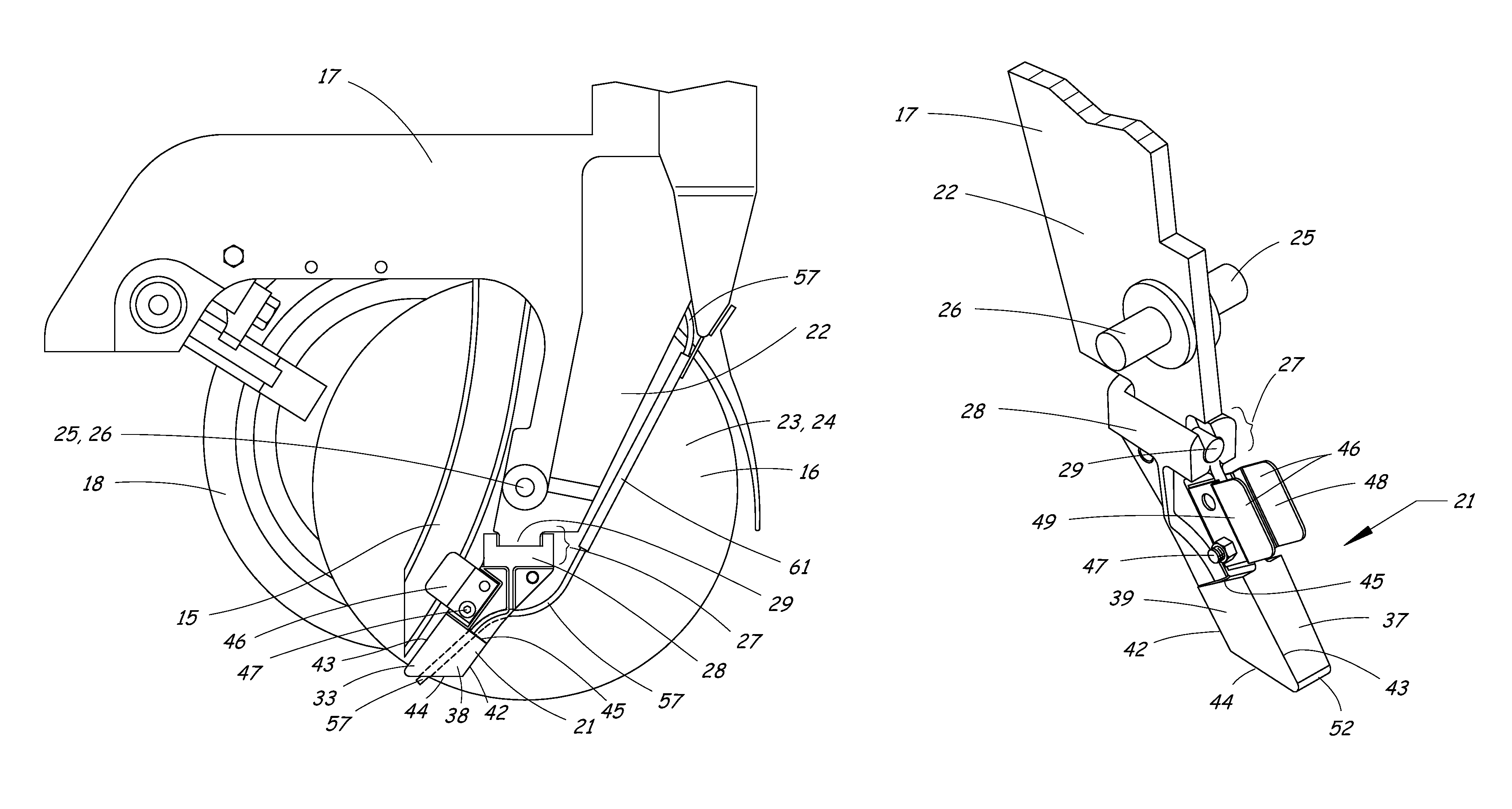

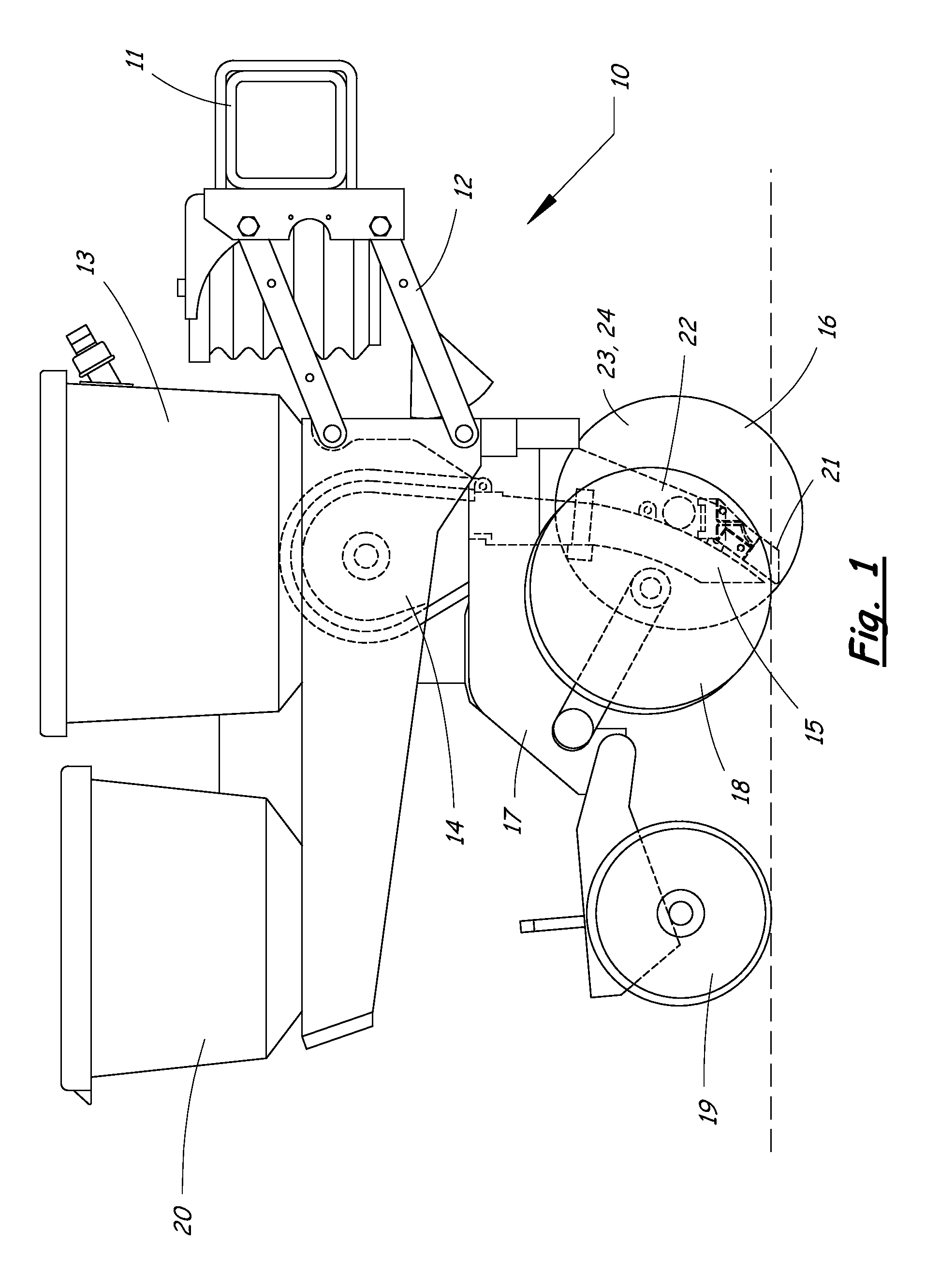

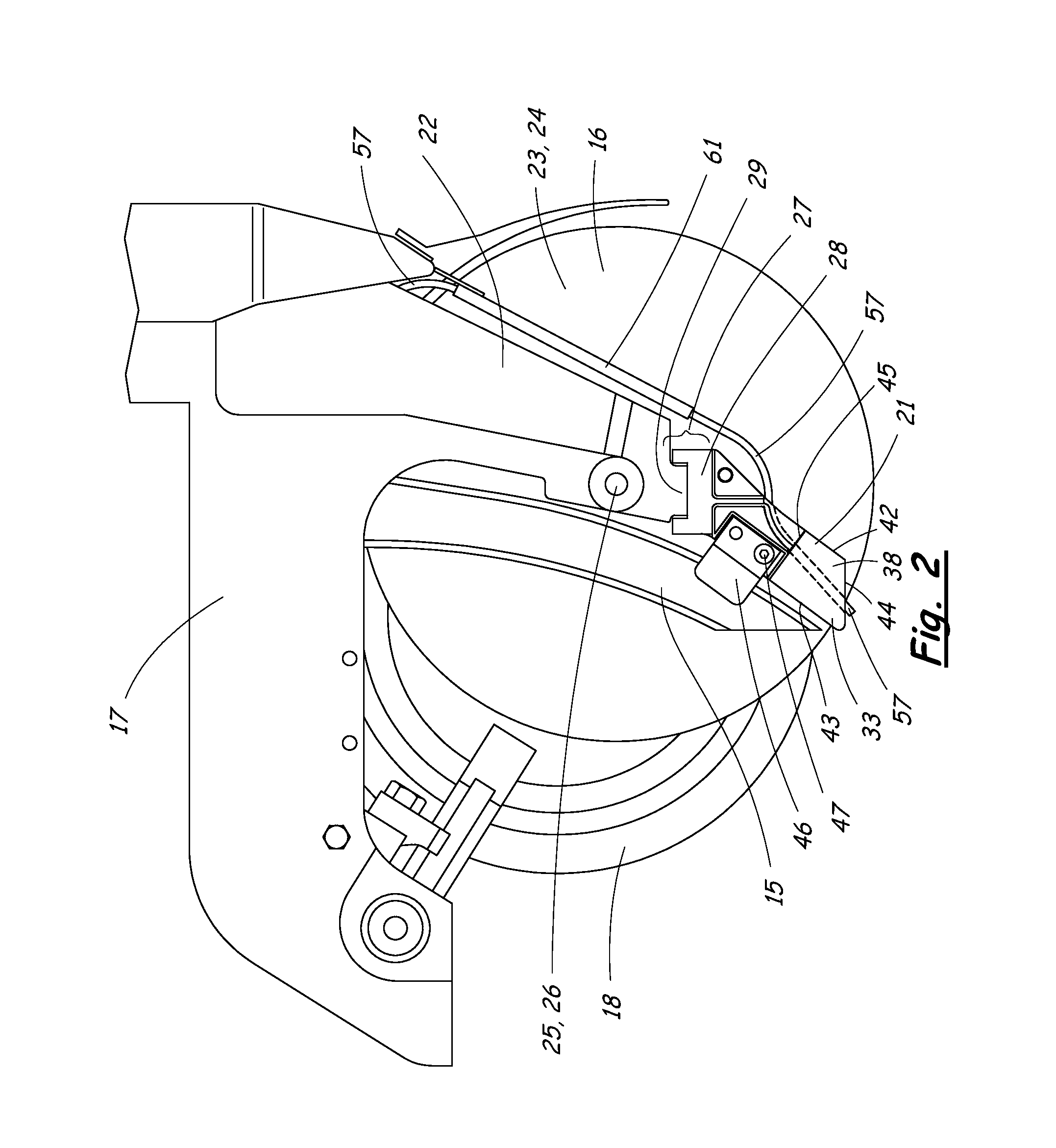

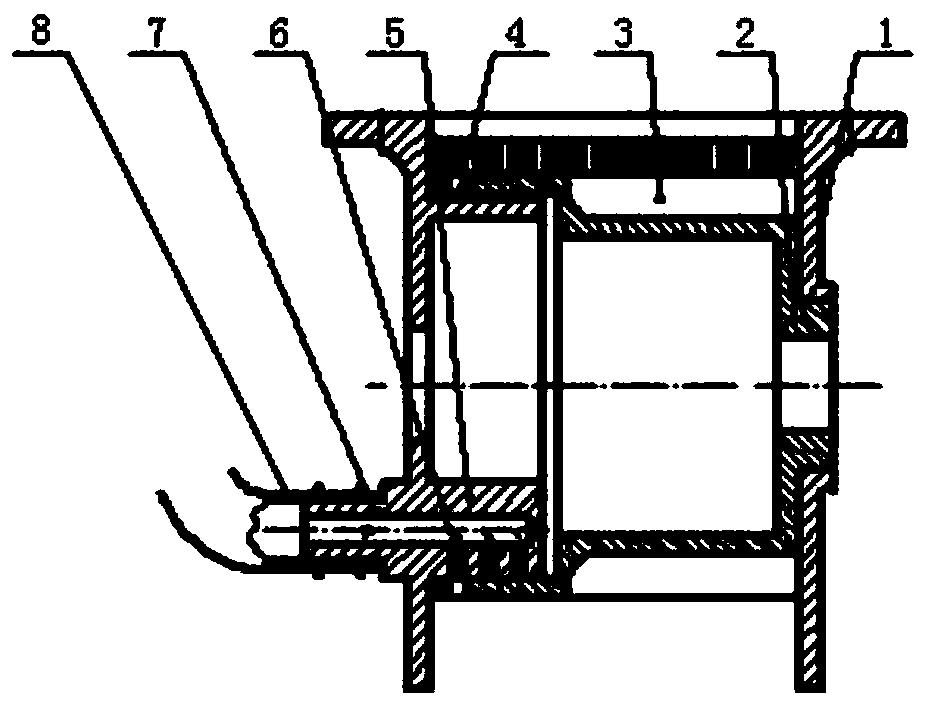

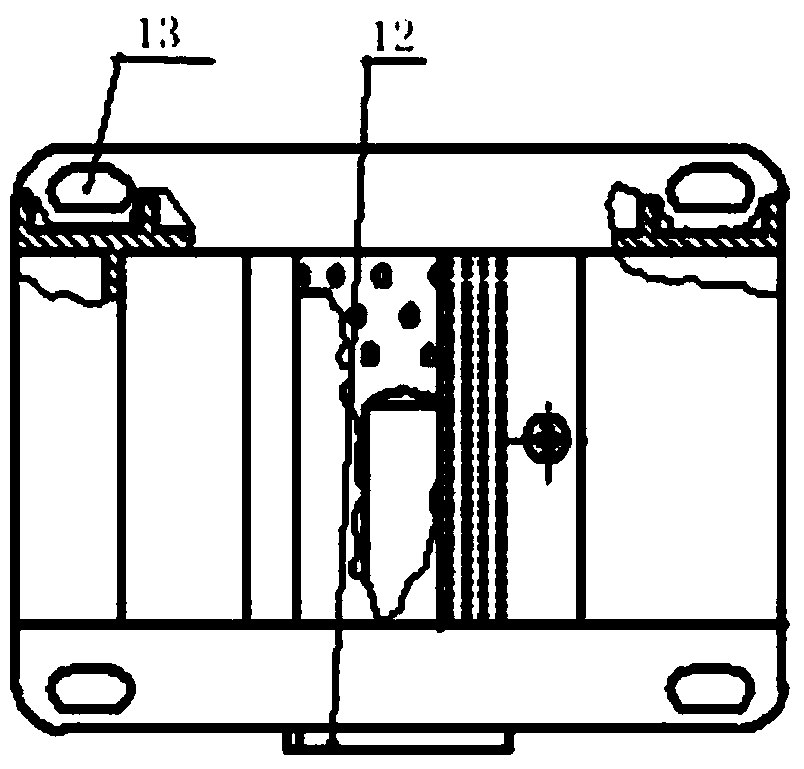

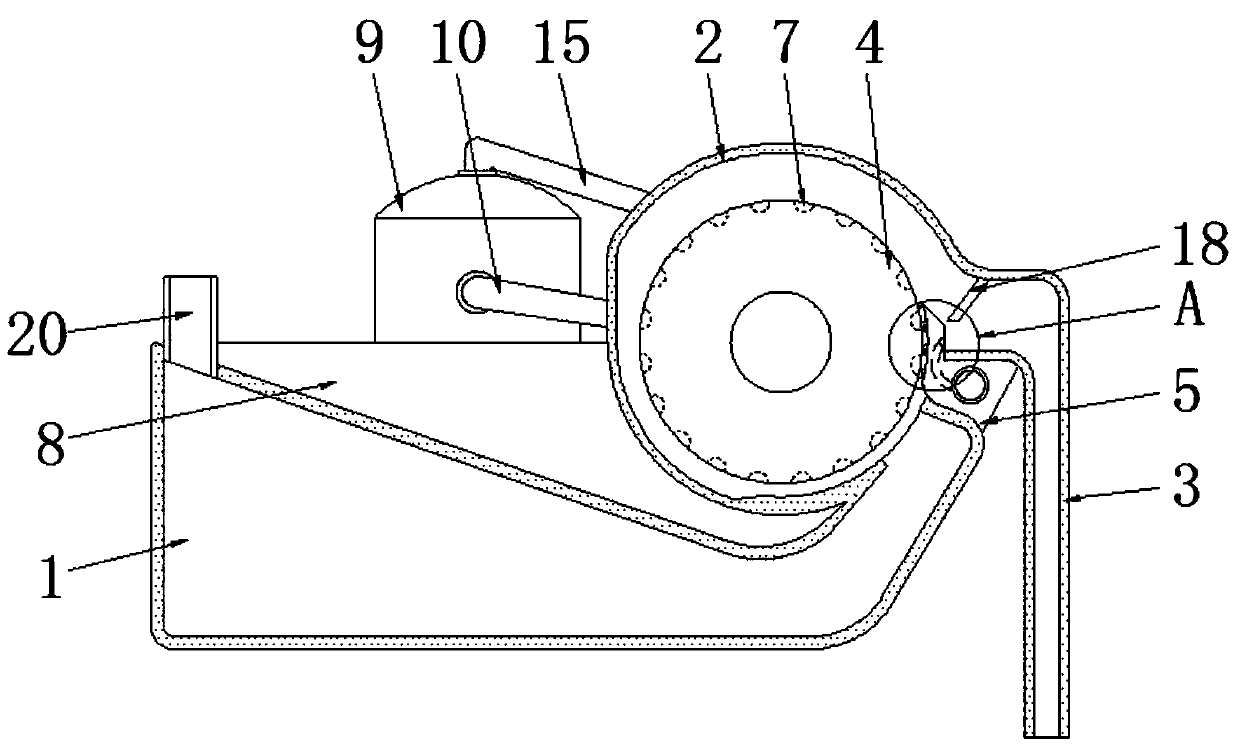

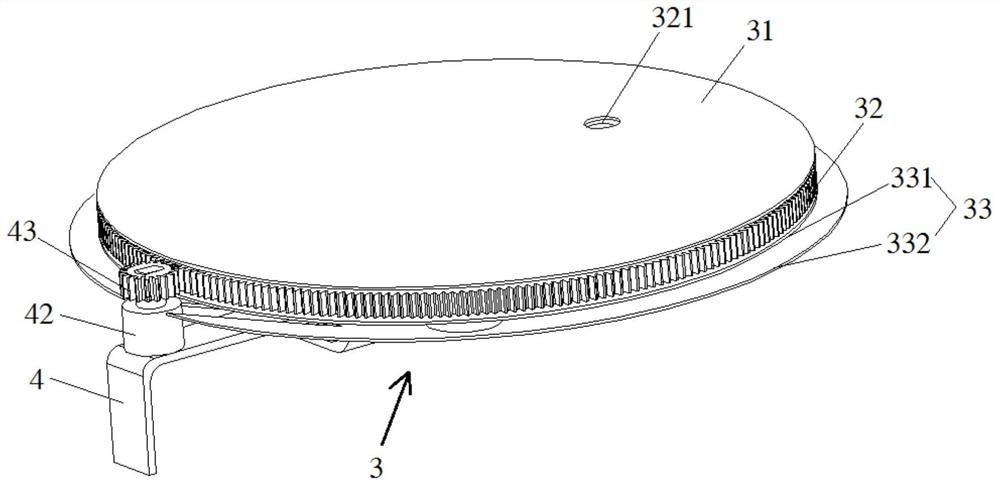

Low friction seed meter

InactiveUS8166896B2Precise sowingReduce the amount requiredFertiliser distributersSowingEngineeringVacuum chamber

The seed meter includes the combination of a vacuum housing and a seed disc coupled together in a sealed manner to form a vacuum chamber. Disposed within the vacuum chamber is a generally flat finger wheel having plural radially extending resilient fingers. Also disposed in the vacuum chamber is a fixed arm. A seed hopper is disposed adjacent the seed disc for providing seeds to an outer surface of the seed disc, with the seeds adhering to the plural spaced apertures on the seed disc's periphery with vacuum applied to the disc's inner surface. A rotary drive spindle rotates the vacuum housing, seed disc and finger wheel combination, with each resilient finger sequentially deflected by the fixed arm to sequentially engage each disc aperture, interrupting vacuum communication with each aperture, for sequentially releasing the seeds.

Owner:KINZE MFG INC

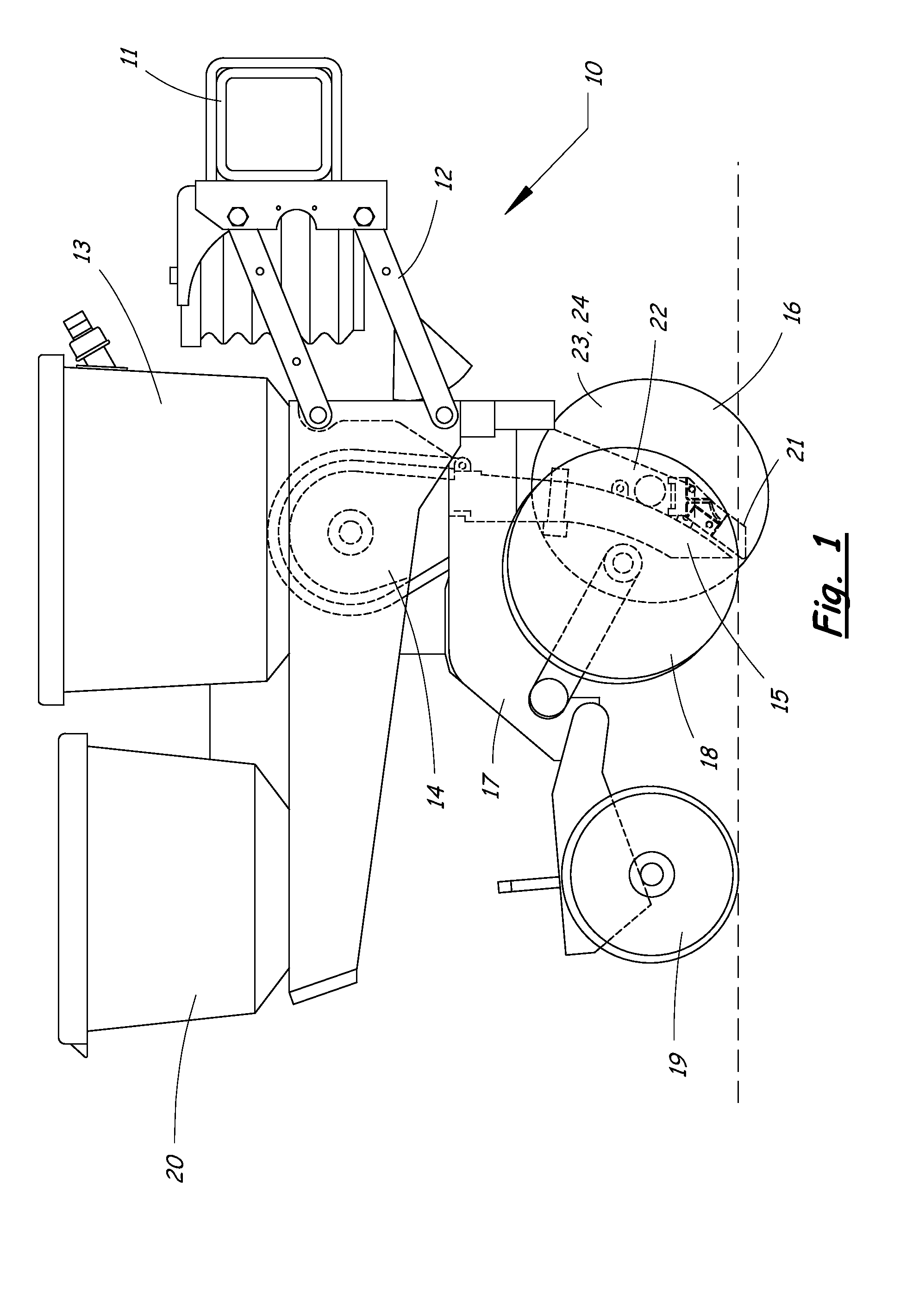

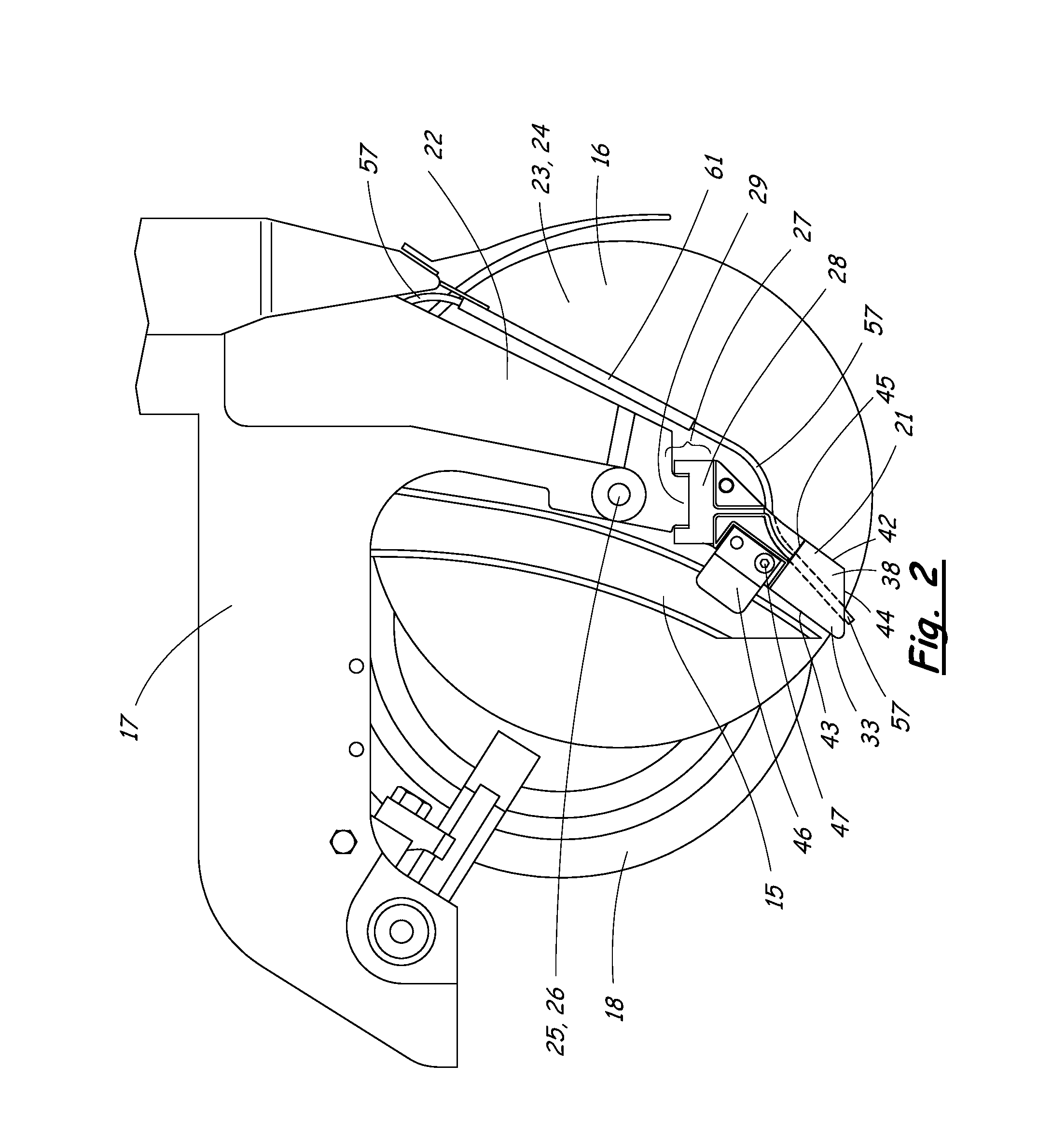

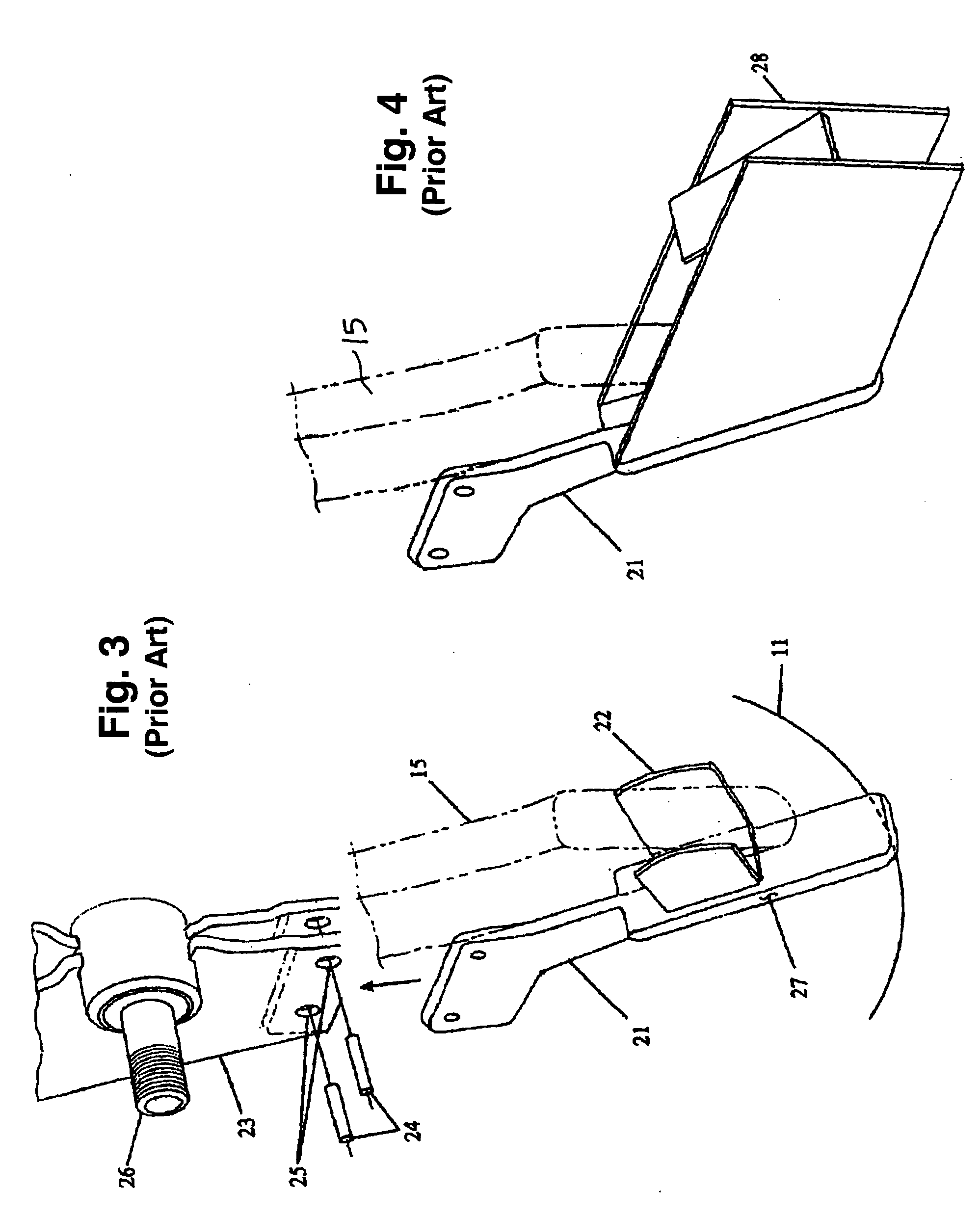

Seed tube guard with integral fluid channel for agricultural planters

ActiveUS20140158031A1Improve wear lifeInexpensive and efficient to manufactureSpadesPlantingWear resistantAgricultural engineering

A seed tube guard for agricultural planters is cast from a high-chrome cast-iron alloy or manufactured from other wear-resistant material. The seed tube guard has right and left wear surfaces for engaging inner surfaces of a pair of opener discs. A fluid delivery channel is integrated within the body of the seed tube guard with an exit in the bottom surface for delivering fluid into a seed furrow ahead of a seed tube.

Owner:DOWNS EMILIE

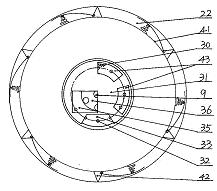

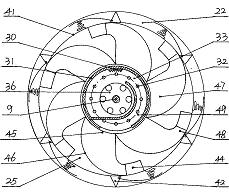

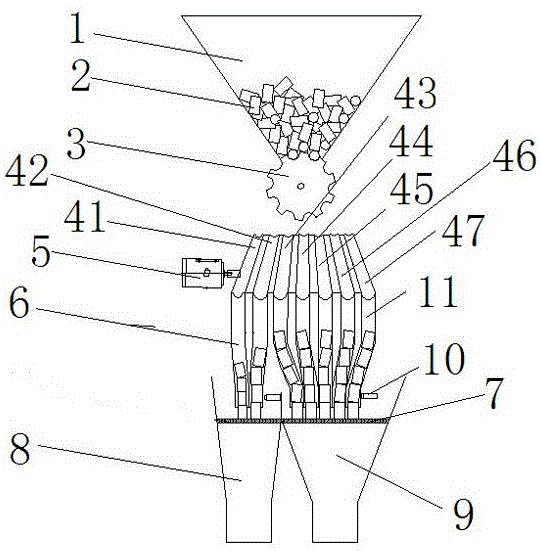

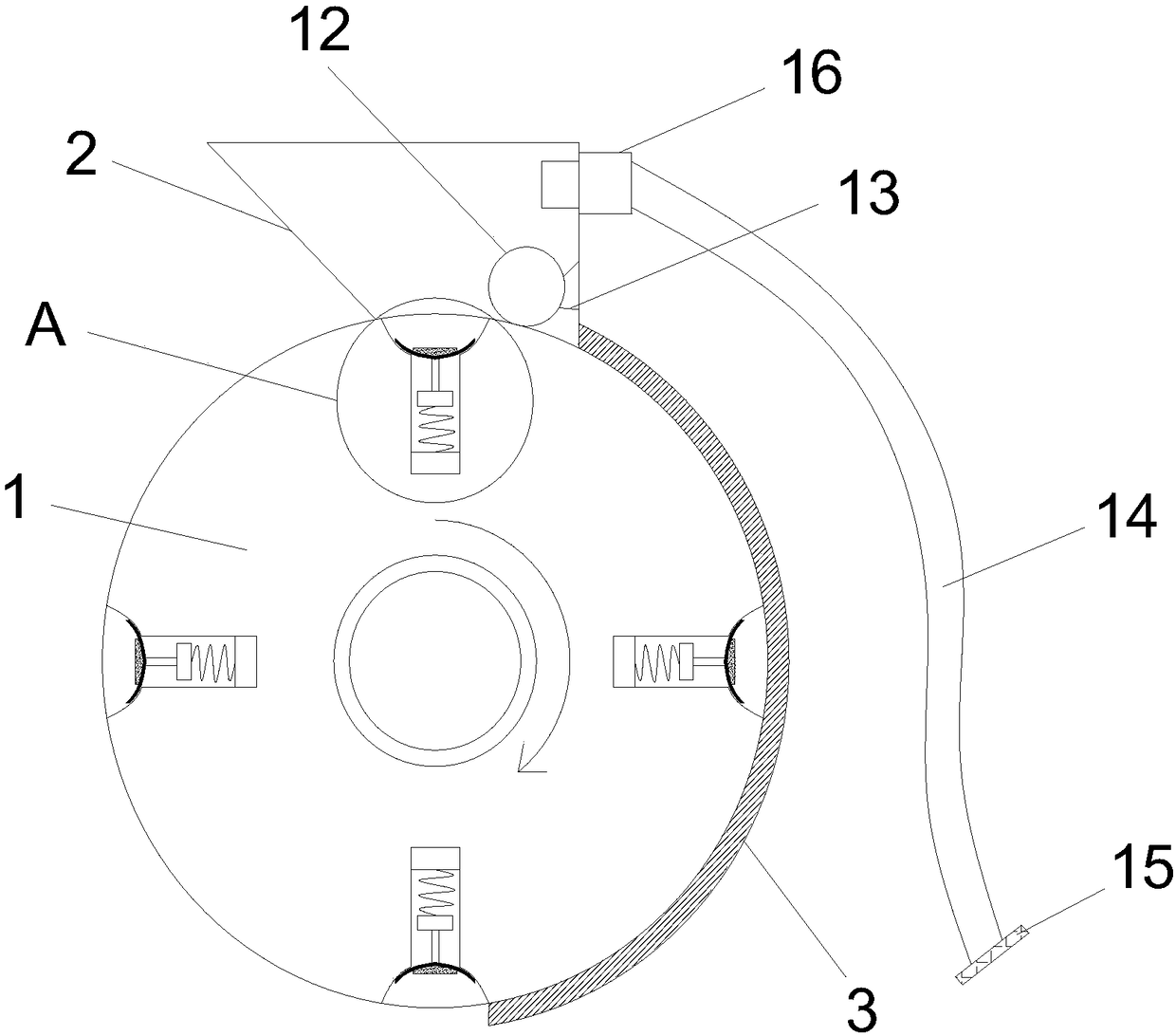

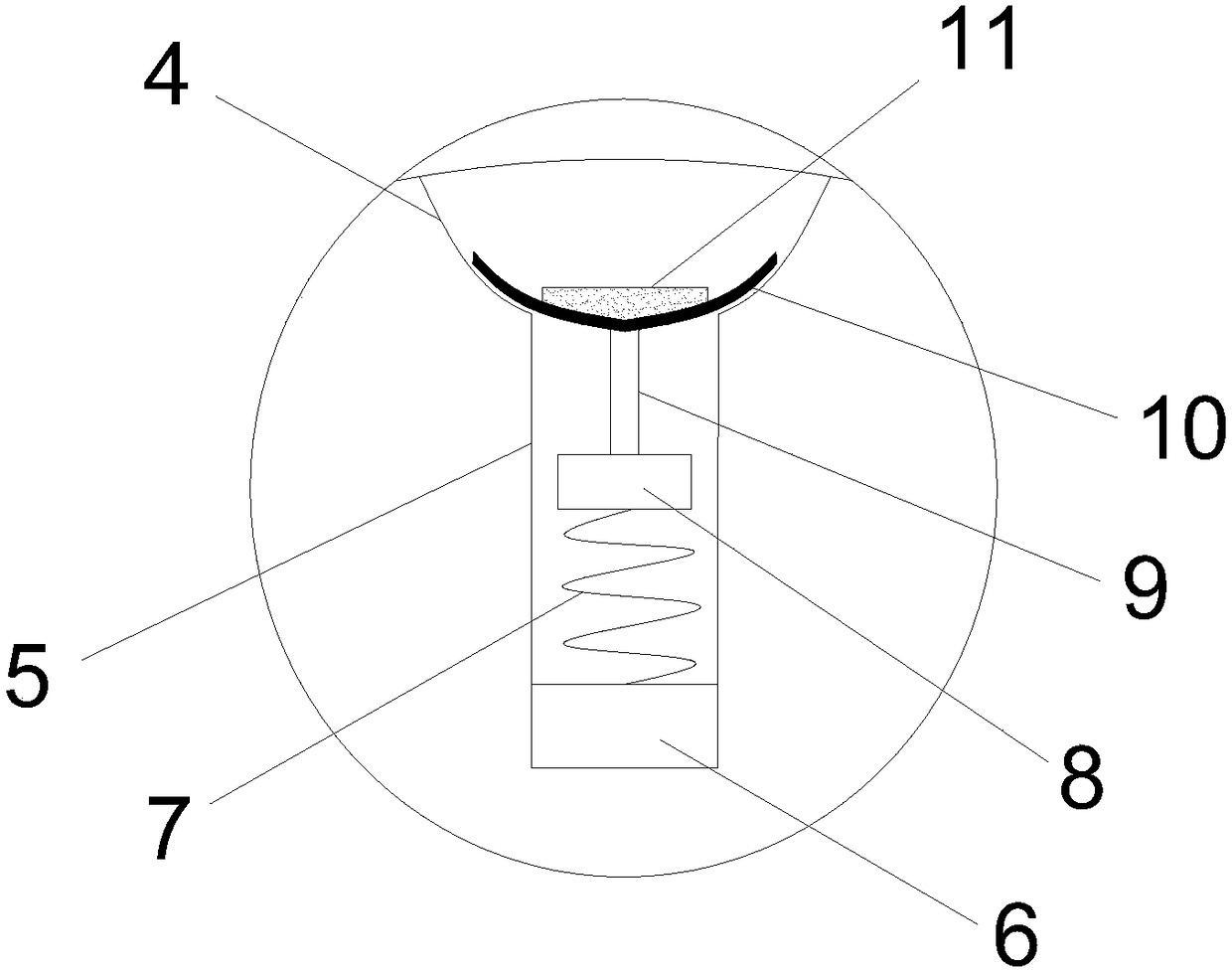

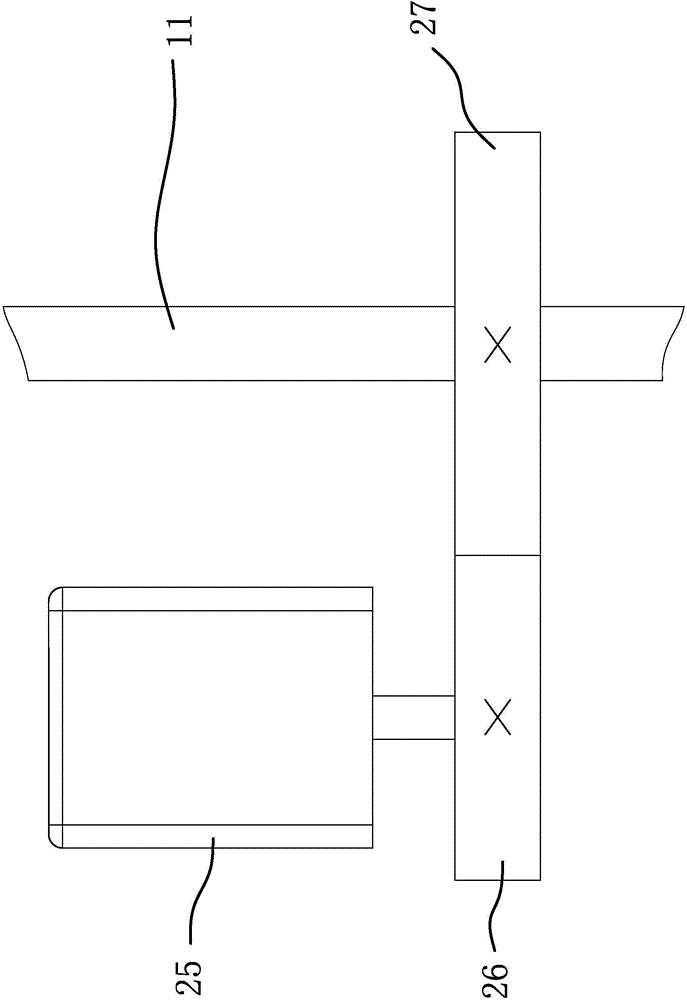

Suction type precision seed bunch planting device

InactiveCN101766078ALarge internal spaceIncrease heightSeed depositing seeder partsRegular seed deposition machinesAgricultural scienceAgricultural engineering

The invention relates to an agricultural seeding device, in particular to a suction type precision seed bunch planting device. The suction type precision seed bunch planting device mainly comprises a seed tank (26), a suction type seed sorter, a roller, a negative pressure air suction pipe (6), a speed shifting mechanism and a seed receiving and delivering device, wherein the suction type seed sorter is arranged in the roller and communicated with the negative pressure air suction pipe (6); a seed delivering box (47) is arranged between a seed outlet of the suction type seed sorter and a duck nozzle (42); a main shaft (4) of the roller is a hollow pipe; a main shaft (9) of the suction type seed sorter is arranged in the hollow pipe-shaped main shaft (4) of the roller; one end of the main shaft (9) of the suction type seed sorter is coupled to the suction type seed sorter through a bearing (8.1) and drives a seed suction disk (33), and the other end of the main shaft (9) of the suction type seed sorter passes through a sealing bearing (8) in the main shaft (4) of the roller; the main shaft (4) of the roller and the main shaft (9) of the suction type seed sorter are in speed-shifting connection through a gear or a chain or a notched belt. The suction type precision seed bunch planting device has the advantages of increasing the inner space of the roller as much as possible, increasing the height of the seed delivering box simultaneously, conveniently regulating the rotating speed ratio of the roller to the seed absorption box according to the agronomic requirements, and greatly improving the seeding speed while seeding accurately. Due to the unique transmission structure, the suction type precision seed bunch planting device is compact and steady, and the fault rate is reduced obviously under the environment of worse working condition.

Owner:陈恒

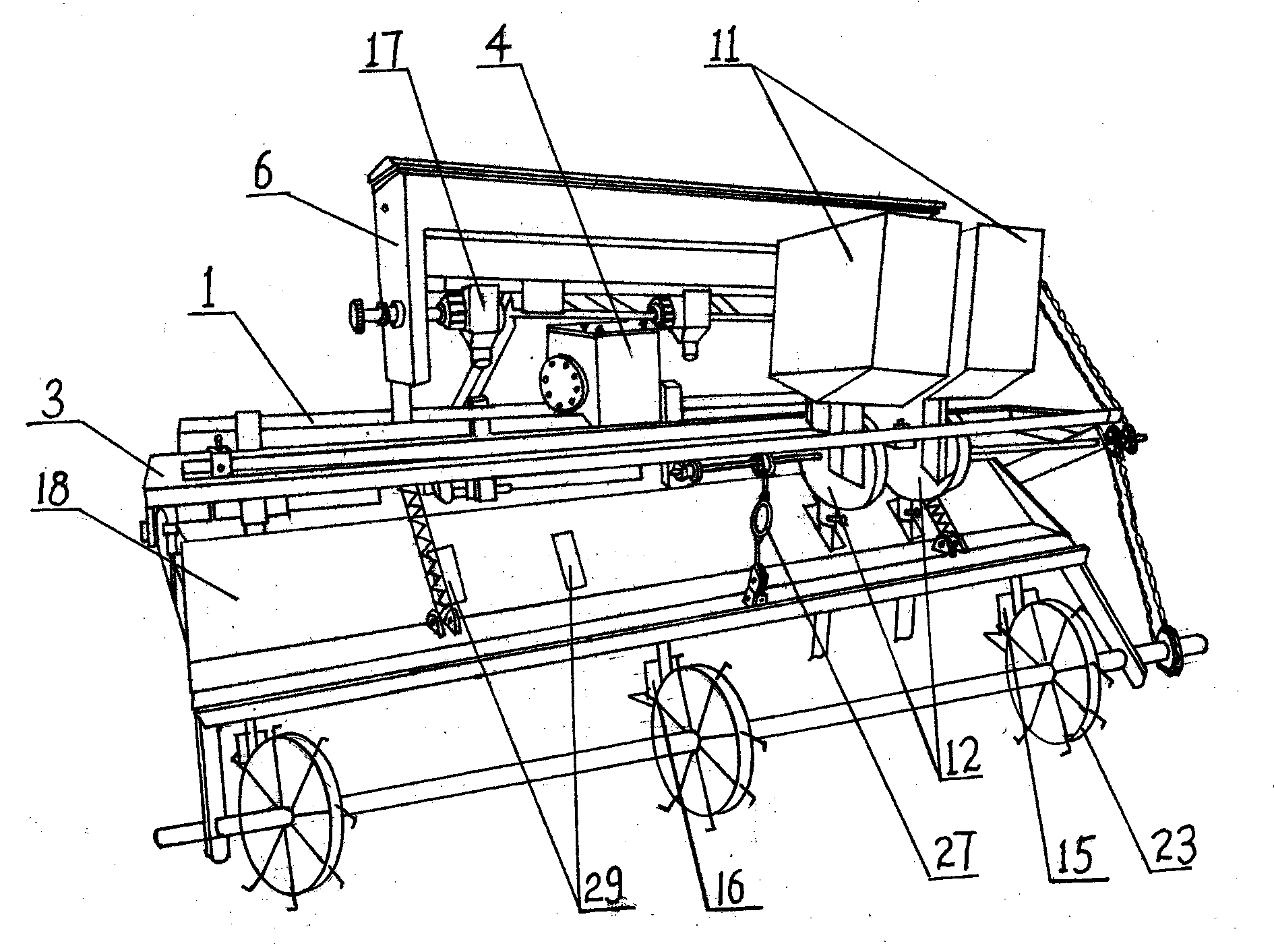

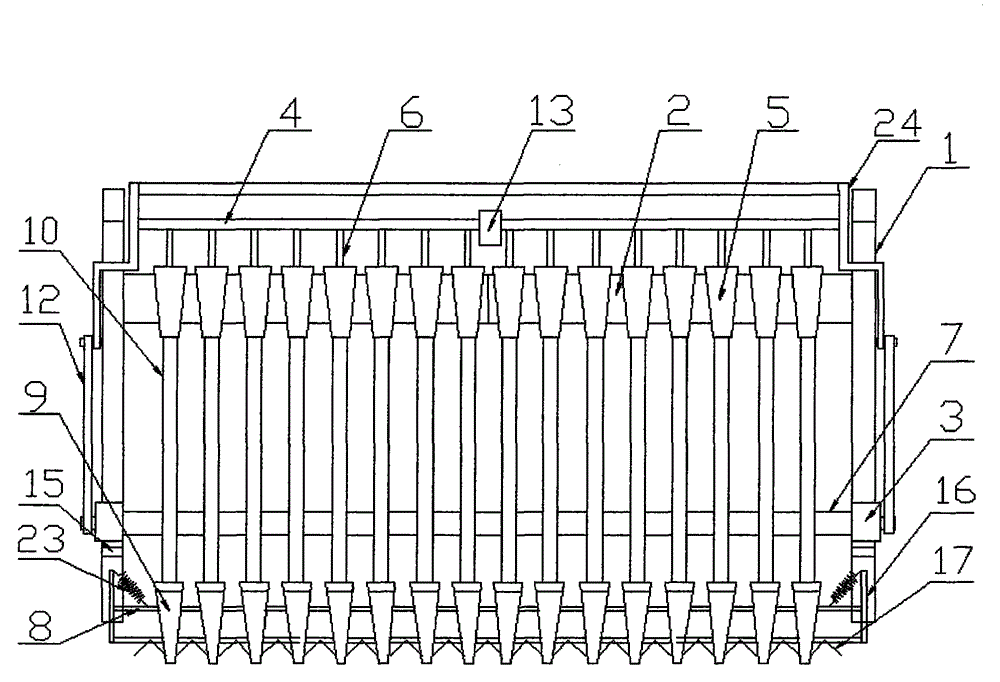

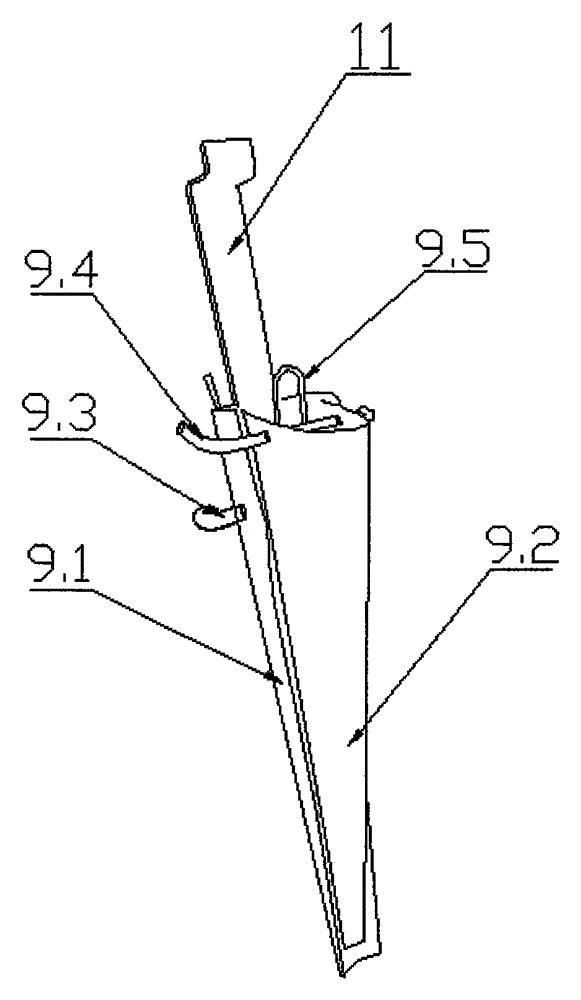

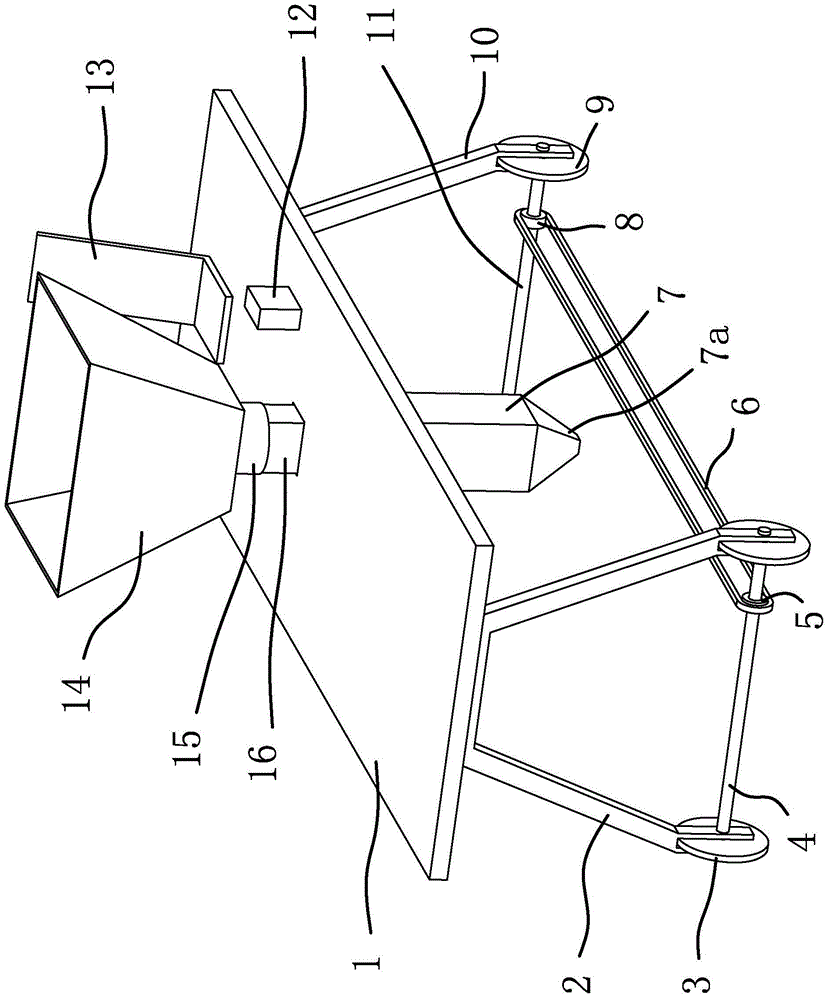

Ginseng seeder

ActiveCN105027765AAvoid wastingSolve the problem that it is impossible to work in the virgin forest with no roadsSeed depositing seeder partsRegular seed deposition machinesSeederBiochemical engineering

The invention relates to a ginseng seeder which comprises guide rails and a seed tank, wherein sliding blocks are arranged on the guide rails; a cross rod I fixed on the guide rails is arranged above the seed tank, and is arranged on rocker arms; a plurality of seed ordering boxes are arranged on the seed tank; seed spoons are arranged on the cross rod I; a cross rod II is fixedly connected onto the sliding block; a cross rod III and U-shaped baffles are arranged below the cross rod II; duck nozzles are arranged on the cross rod III; a guide pipe is arranged between each duck nozzle and the corresponding seed ordering box; inner soil cleaning devices capable of moving in the duck nozzles are arranged on the cross rod II; the sliding blocks, the rocker arms and the connecting rods I form a connecting rod sliding block mechanism; a vibrator is arranged on the cross rod I; the vibrator is controlled through a travel switch. The ginseng seeder can be operated by only needing two persons, the production efficiency can be improved, and the sowing which is high in precise and free of seed damage is realized.

Owner:张增林 +2

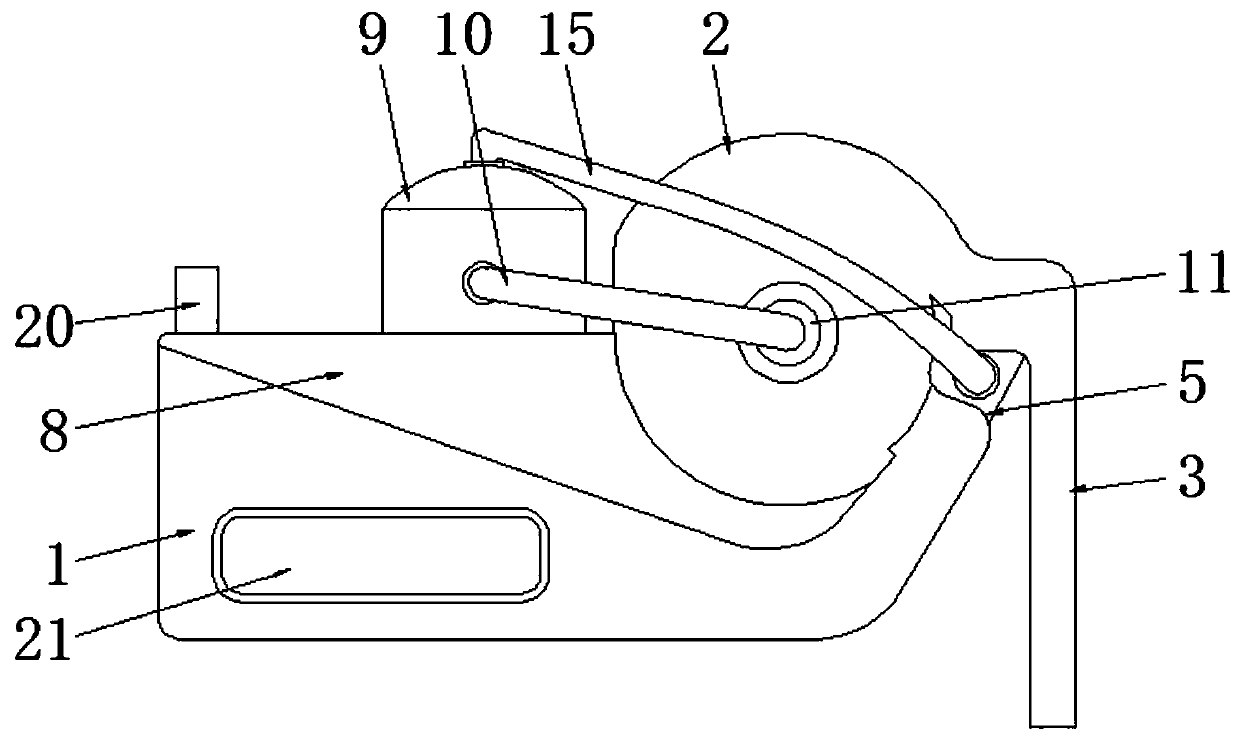

Single-bud-section seed sowing device for sugar cane seeds

The invention discloses a single-bud-section seed sowing device for sugar cane seeds and belongs to the technical field of agricultural machinery. The seed sowing device comprises a seed box, wherein a sorting shifting wheel with grooves is arranged at an outlet of the bottom end of the seed box, a vibrating screen is correspondingly arranged below the sorting shifting wheel, multiple parallel seed passing grooves are formed in the upper surface of the vibrating screen, the upper surface of the vibrating screen inclines downwards, a corresponding push cylinder is arranged at the upper end of each seed passing groove, lower ends of the seed passing grooves are connected with seed guiding pipes, a baffle is arranged at lower parts of discharging ports of the seed guiding pipes, the distance between the baffle and ends of the discharging ports of the seed guiding pipes is smaller than the length of sugar cane seeds, the baffle is arranged in a seed sowing pipe, and a seed sowing and shifting wheel is arranged above the baffle in a matched manner and connected with a driving device. The device is relatively simple in structure, easy to produce and high in seed sowing quantity accuracy.

Owner:ANYANG INST OF TECH

Rice seedling sowing mechanism matched with rice seedling sowing machine with stepless and rapidly-adjustable row space

The invention relates to a rice seedling sowing mechanism matched with a rice seedling sowing machine with stepless and rapidly-adjustable row space. The rice seedling sowing mechanism comprises a seedling collecting bucket, a seedling placing device, a rice nutritional bowl box plate, and a rice seedling grabbing mechanism. The rice nutritional bowl box plate and the rice seedling grabbing mechanism are arranged above the seedling collecting bucket. The seedling placing device is placed inside the seedling collecting bucket, and is provided with a step motor, a synchronous tooth-shaped belt, a synchronous tooth-shaped belt wheel, and two parallel synchronous conveying belts formed by flexible projections, wherein the flexible projections are uniformly arranged and fixed on the synchronous tooth-shaped belt. The rice seedling grabbing mechanism grabs the rice nutritional bowl placed on the rice nutrition bowl box plate, and places the rice nutritional bowl on the seedling collecting bucket between the two parallel synchronous conveying belts. The bottom of the seedling collecting bucket is provided with a seedling discharge port. The two parallel synchronous conveying belts with the flexible projections of the seedling placing device push the rice nutritional bowl on the seedling collecting bucket, such that the rice nutritional bowl glides to the seedling discharge port of the seedling collecting bucket so as to sow the seedling into the field. According to the present invention, the rice seedling sowing mechanism of the present invention has characteristics of stable operation, compact structure, and flexible operation, and is suitable for the rice sowing operation with characteristics of precise sowing and less seed injuring; and the requirements of precise sowing, accurate seed placing, cavity reducing and high efficiency can be met.

Owner:YANGZHOU UNIV

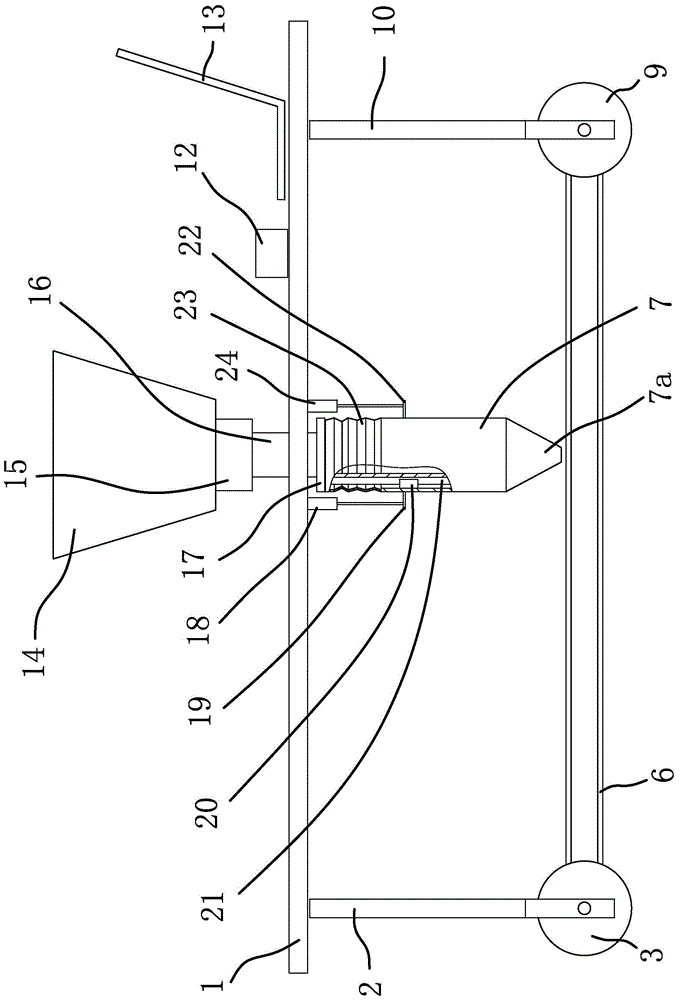

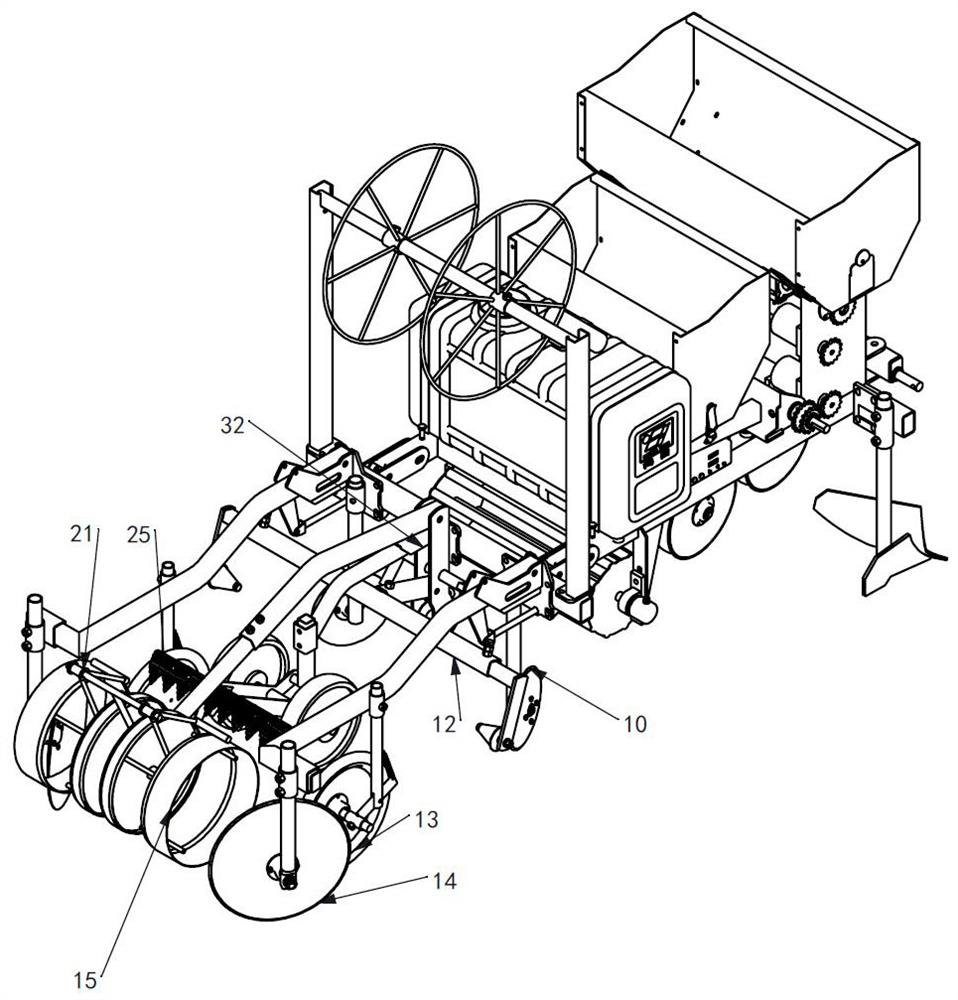

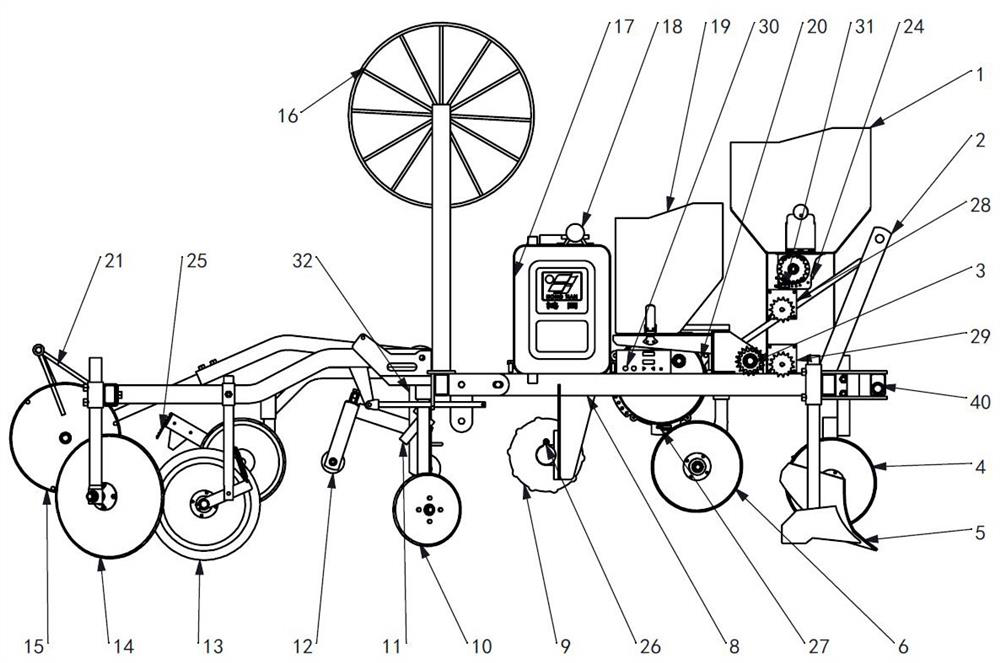

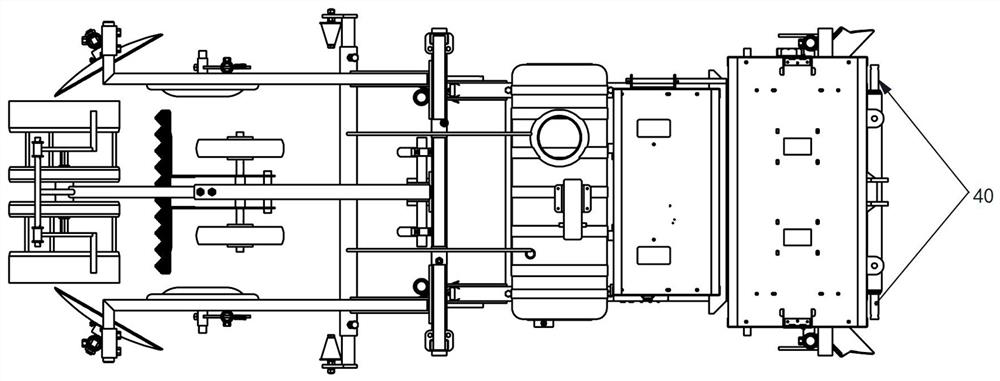

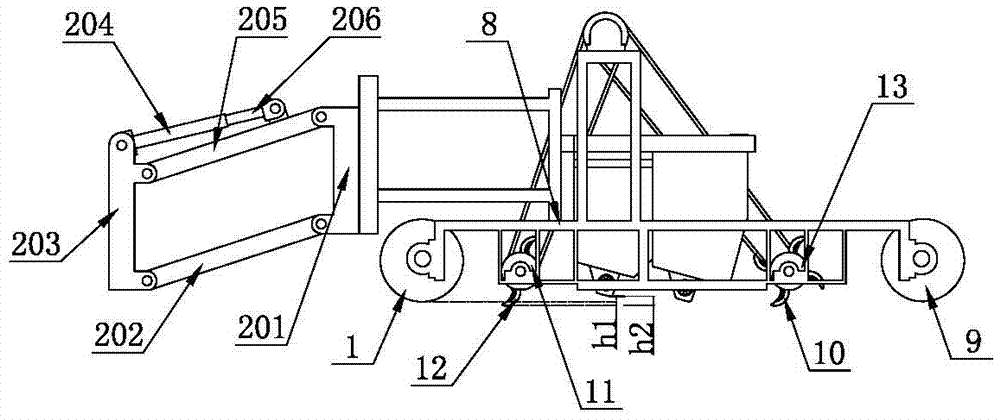

Multi-functional quinoa sower

PendingCN108901263AShorten germination timeSimple structurePlantingWatering devicesEngineeringTractor

The invention relates to a multi-functional quinoa sower. The multi-functional quinoa sower comprises a machine frame; a pull rack is arranged at the front end of the machine frame, and is used for connecting with a tractor; a film covering mechanism is arranged at the rear end of the machine frame; a ditching mechanism, a soil covering mechanism and a packer wheel are sequentially arranged, alongfront-to-back direction, at the bottom of the machine frame; a sowing mechanism, a fertilizing mechanism and a watering mechanism are sequentially mounted, along front-to-back direction, at the top of the machine frame; an outlet end of a seed discharge tube of the sowing mechanism extends to a rear side of the ditching mechanism; a material discharge end of a material discharge tube of the fertilizing mechanism extends to a rear side of the outlet end; the soil covering mechanism is located behind the material discharge end of the material discharge tube; and the watering mechanism is located above a rear side of the packer wheel. The multi-functional quinoa sower has the beneficial effect of being simple in structure, and is capable of synchronously completing a plurality of operations,including ditching, sowing, fertilizing, soil covering, watering, film covering and the like; and thus, the quinoa sower is various in functions and high in applicability.

Owner:CORN RES INST SHANXI ACAD OF AGRI SCI

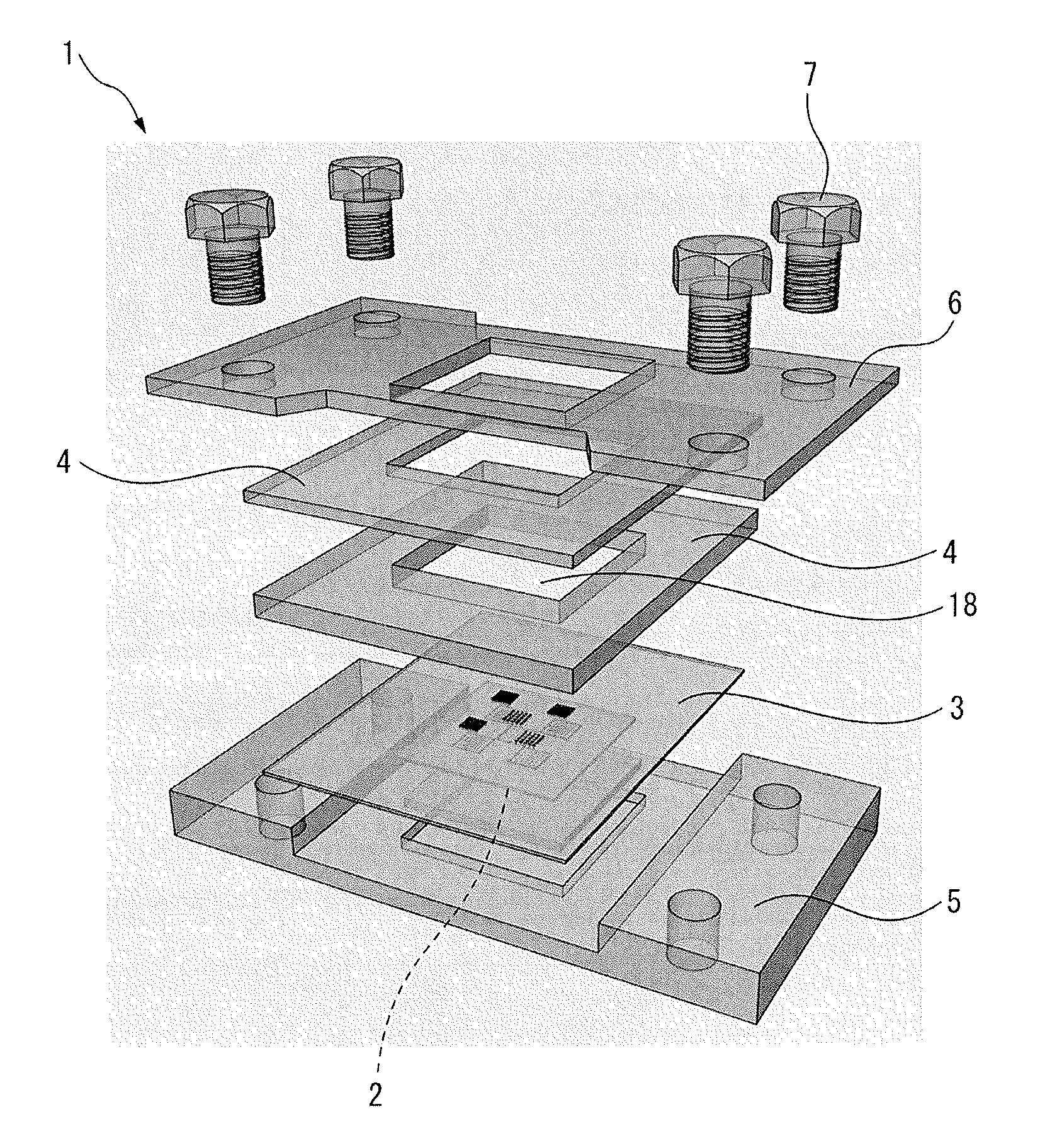

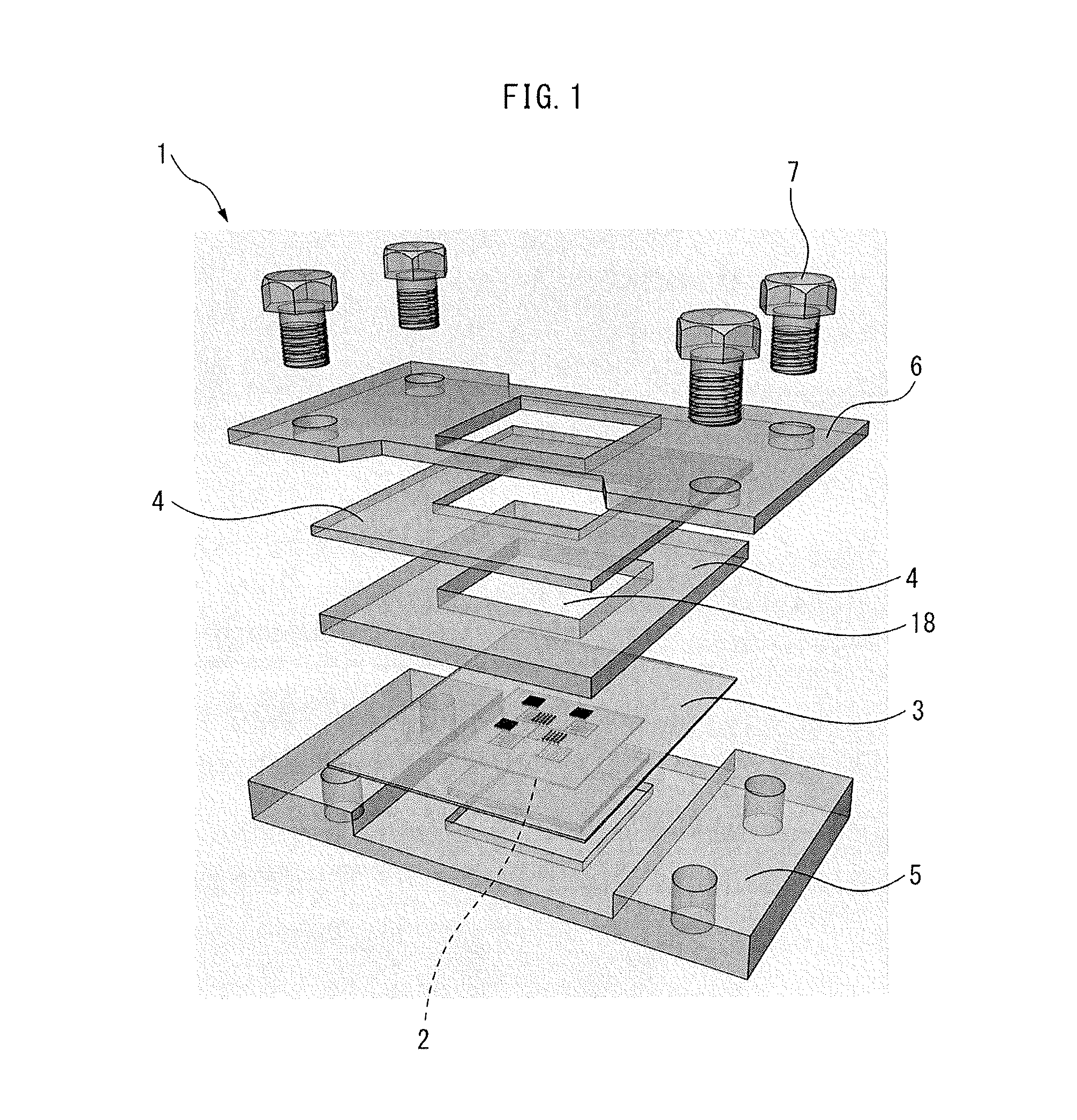

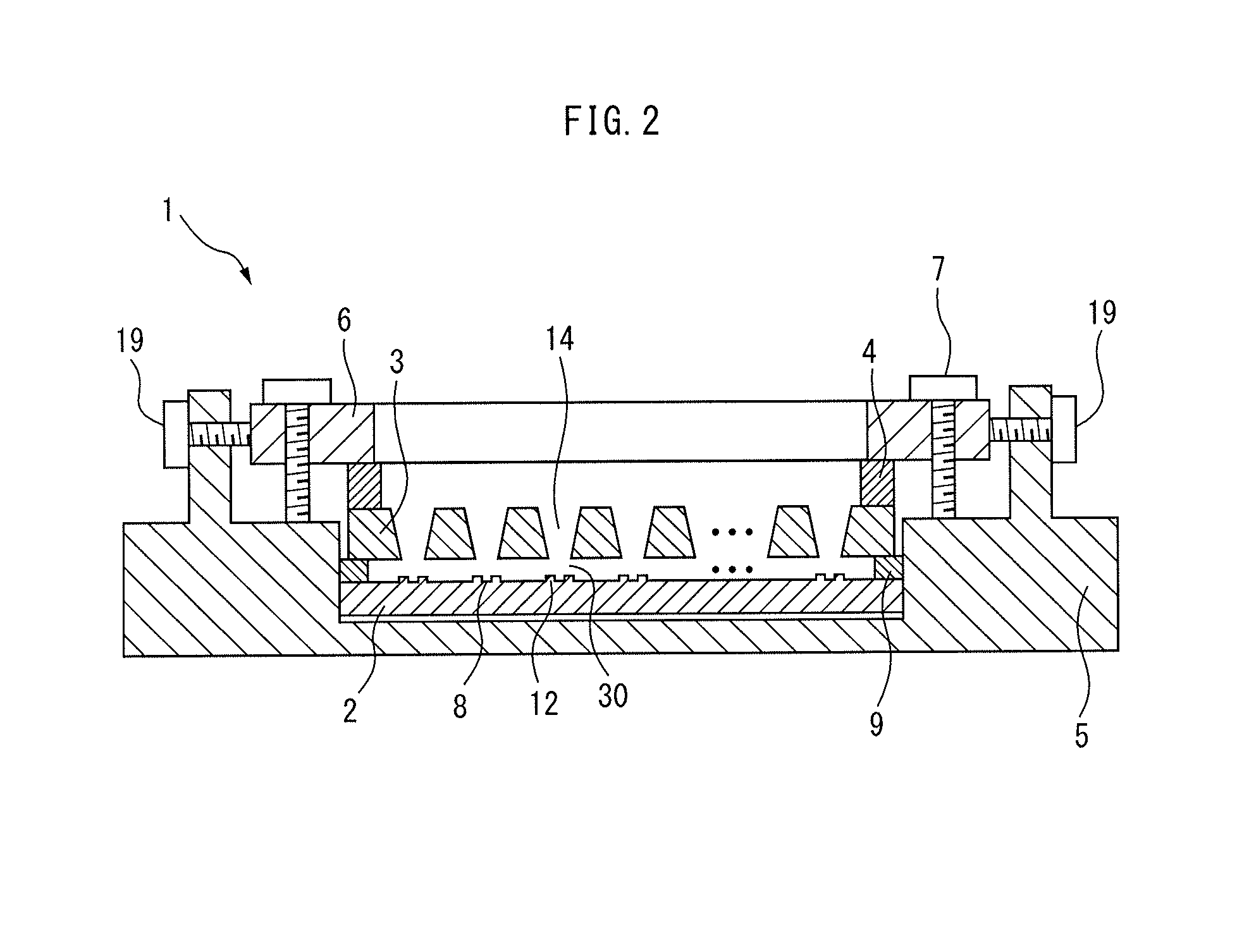

Cell-seeding and -culturing device

ActiveUS20170002315A1Short period of timeSimple procedureApparatus sterilizationNervous system cellsCell culture mediaEngineering

Provided is a device for seeding cells in a plurality of cell arrangement areas in a simple manner and a short period of time. A seeding and culturing device (1) for cells capable of forming a nerve network, the device comprising a cell-culturing substrate (2) having a plurality of cell arrangement areas (8) enclosed by a plurality of projecting parts, and a flow channel substrate (3) arranged on the cell-cultivating substrate (2) and having a plurality of through-holes (14), wherein the through-holes (14) are configured so as to provide flow channels in which the upper surface side of the substrate is an entrance (15) and the lower surface side of the substrate is an exit, and the exit (16) of the flow channels is positioned above any of the cell arrangement areas.

Owner:JAPAN SCI & TECH CORP

Low friction seed meter

InactiveUS20110226168A1Precise sowingReduce the amount requiredFertiliser distributersPotato plantersEngineeringLow friction

The seed meter includes the combination of a vacuum housing and a seed disc coupled together in a sealed manner to form a vacuum chamber. Disposed within the vacuum chamber is a generally flat finger wheel having plural radially extending resilient fingers. Also disposed in the vacuum chamber is a fixed arm. A seed hopper is disposed adjacent the seed disc for providing seeds to an outer surface of the seed disc, with the seeds adhering to the plural spaced apertures on the seed disc's periphery with vacuum applied to the disc's inner surface. A rotary drive spindle rotates the vacuum housing, seed disc and finger wheel combination, with each resilient finger sequentially deflected by the fixed arm to sequentially engage each disc aperture, interrupting vacuum communication with each aperture, for sequentially releasing the seeds.

Owner:KINZE MFG INC

Seed tube guard with integral fluid channel for agricultural planters

ActiveUS8978564B2Prolong lifeInexpensive and efficient to manufactureSpadesDirect liquid fertiliser deliveryWear resistantAgricultural engineering

Owner:DOWNS EMILIE

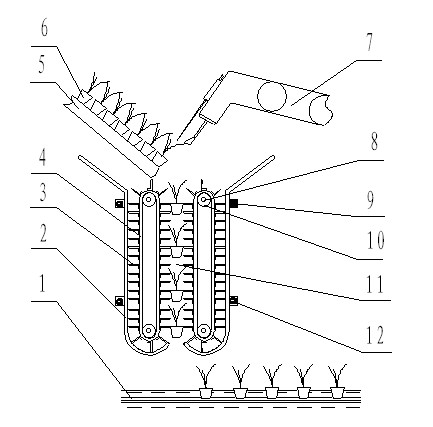

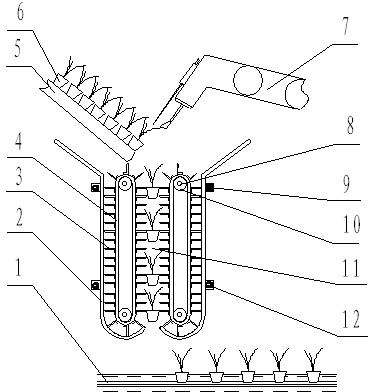

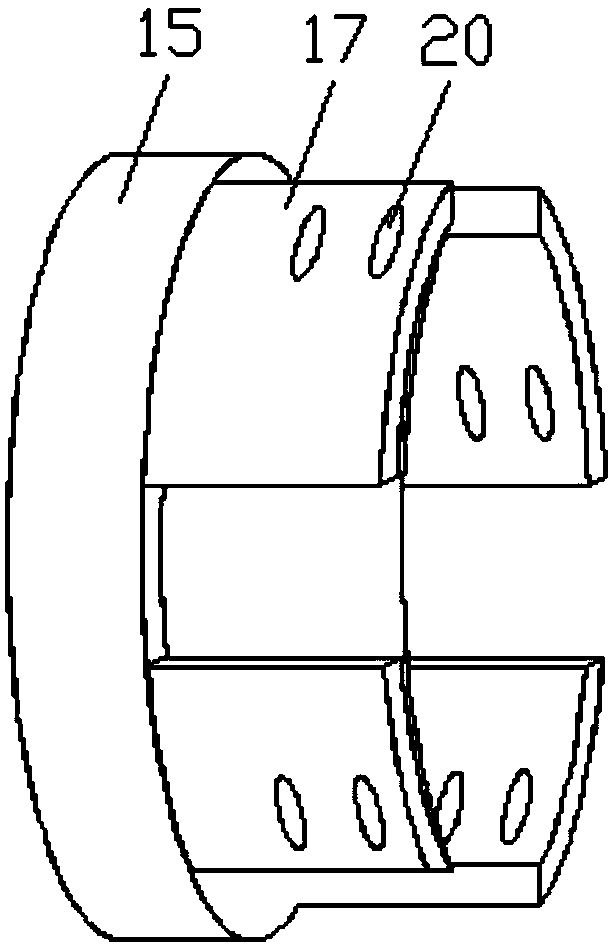

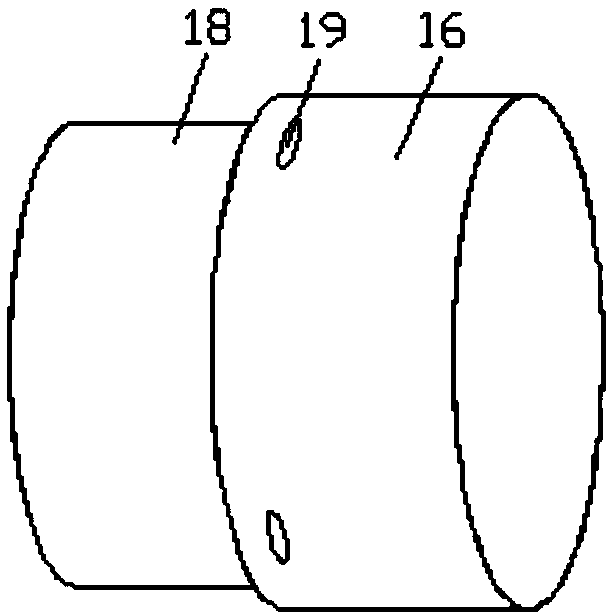

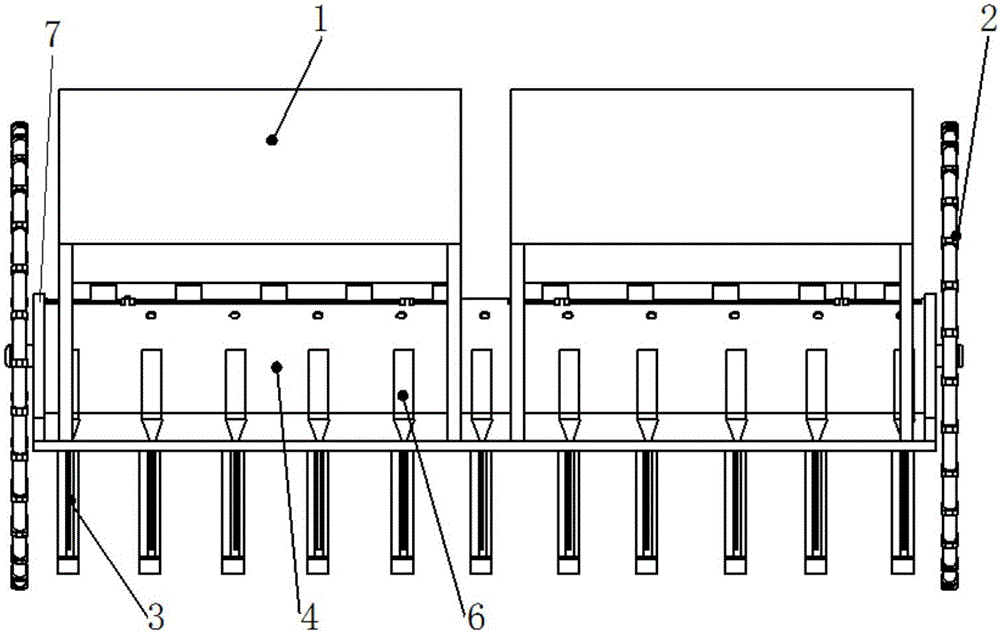

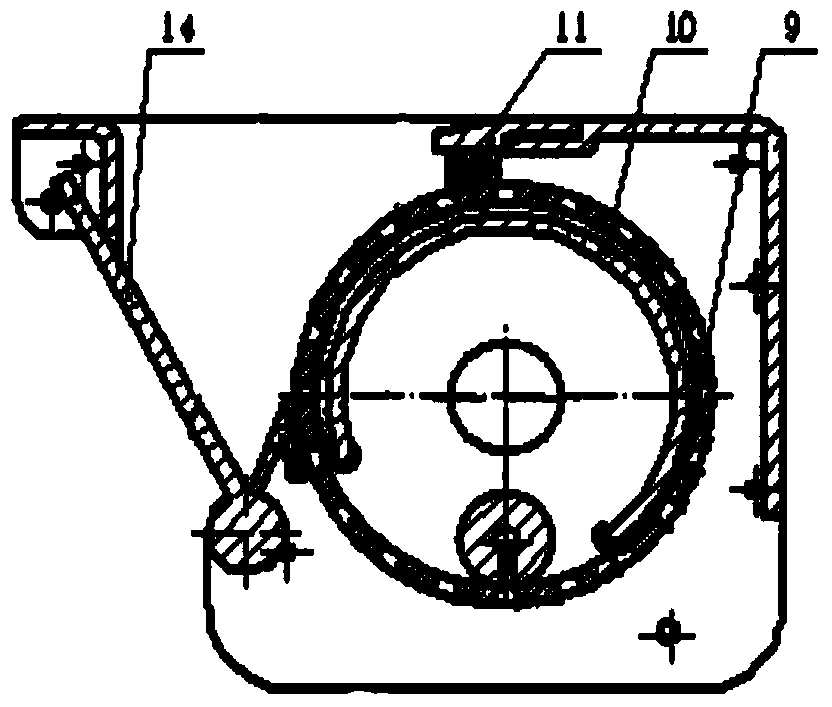

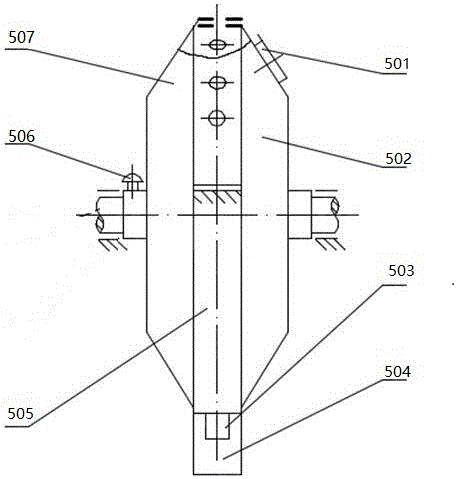

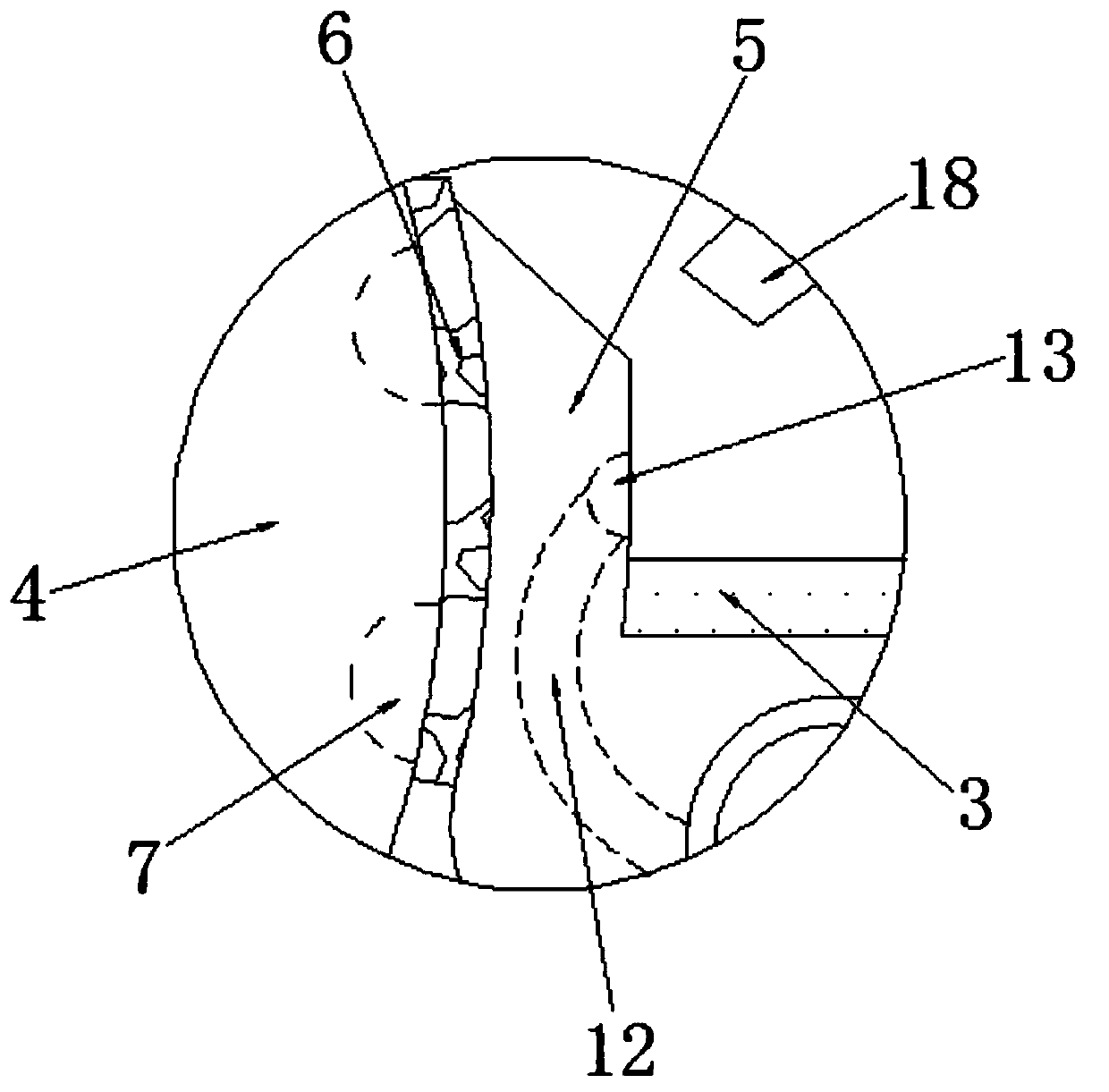

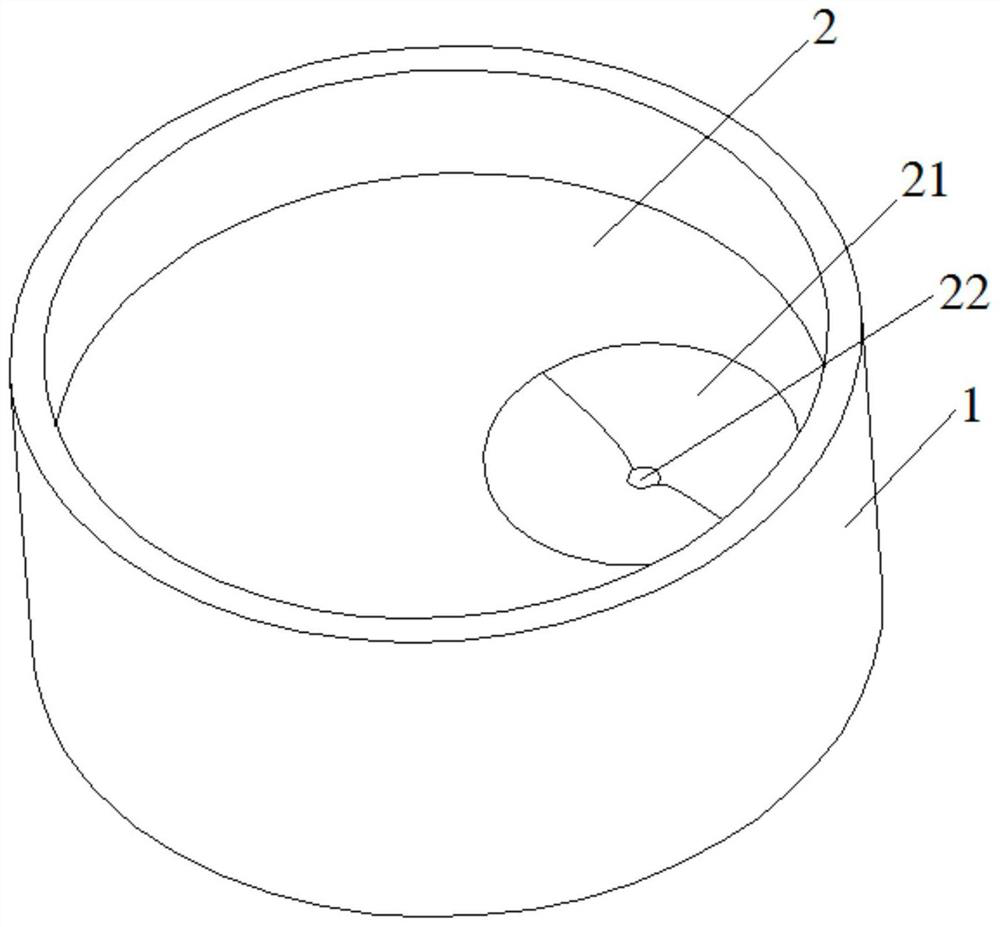

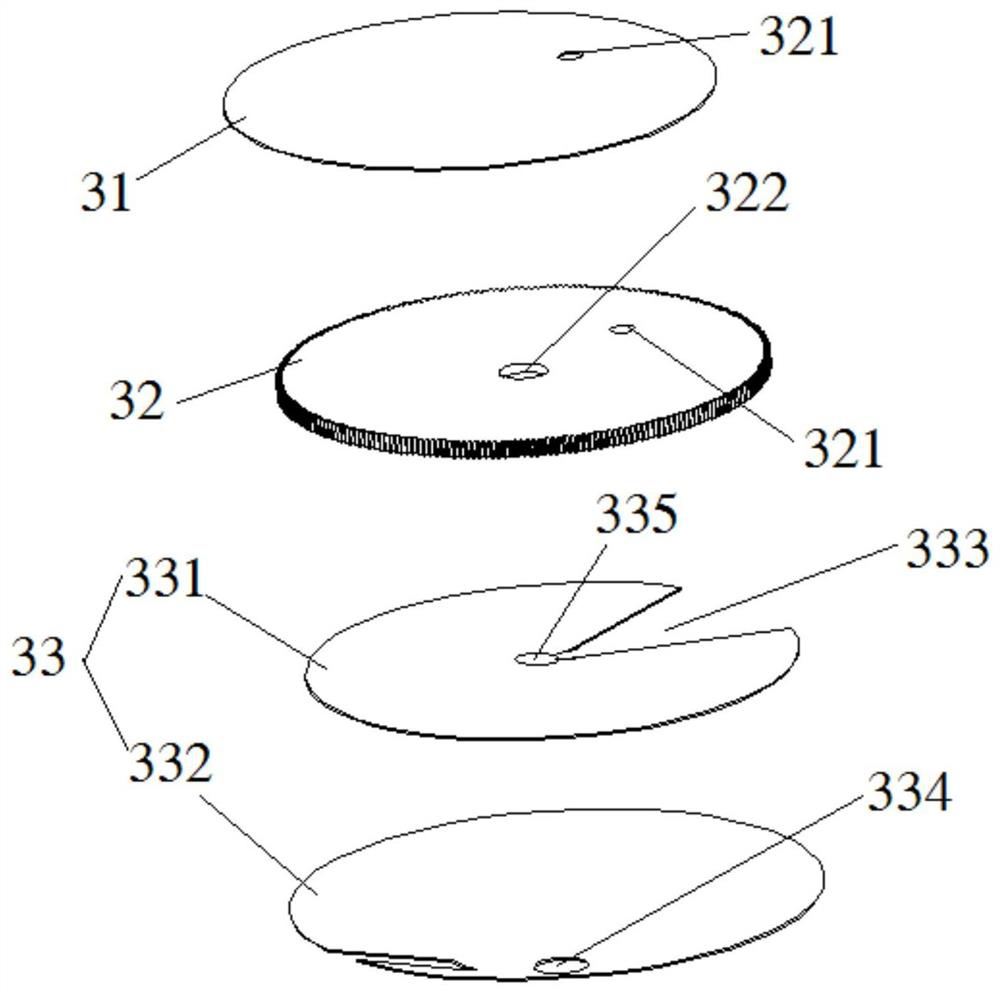

Drum type rice precise hill seeder

InactiveCN106376277ALow levelness requirements for soil preparationPrecise sowingPlantingDibble seedersSeederTraction frame

The invention discloses a drum type rice precise hill seeder, which comprises seed boxes, walking wheels, furrowing devices, a drum device, a traction frame and seed conveying devices, wherein the drum device is arranged on the traction frame, and comprises a tube body; seed collecting openings are formed in the upper end surface of the tube body; a cover plate buckled with each seed collecting opening is arranged in each seed collecting opening position; seed discharging openings distributed at equal intervals are uniformly distributed in the outer circumferential surface of the tube body; a round baffle plate vertical to the axial direction of the tube body is arranged in the tube body between the adjacent seed discharging openings; the walking wheels synchronously rotating together with the drum device are arranged at two ends of the drum device; the seed boxes are arranged at the upper side of the drum device; the lower side of the drum device is provided with the matched seed conveying devices; the furrowing device is arranged at the bottom end of each conveying device. The drum type rice precise hill seeder has the advantages that the structure design is reasonable; rice seeds are in square lattice distribution; rice seeds are enabled to be precisely sowed without damage; the mechanical structure is simple and reliable; the manufacturing cost is low; the popularization is convenient.

Owner:ANHUI AGRICULTURAL UNIVERSITY

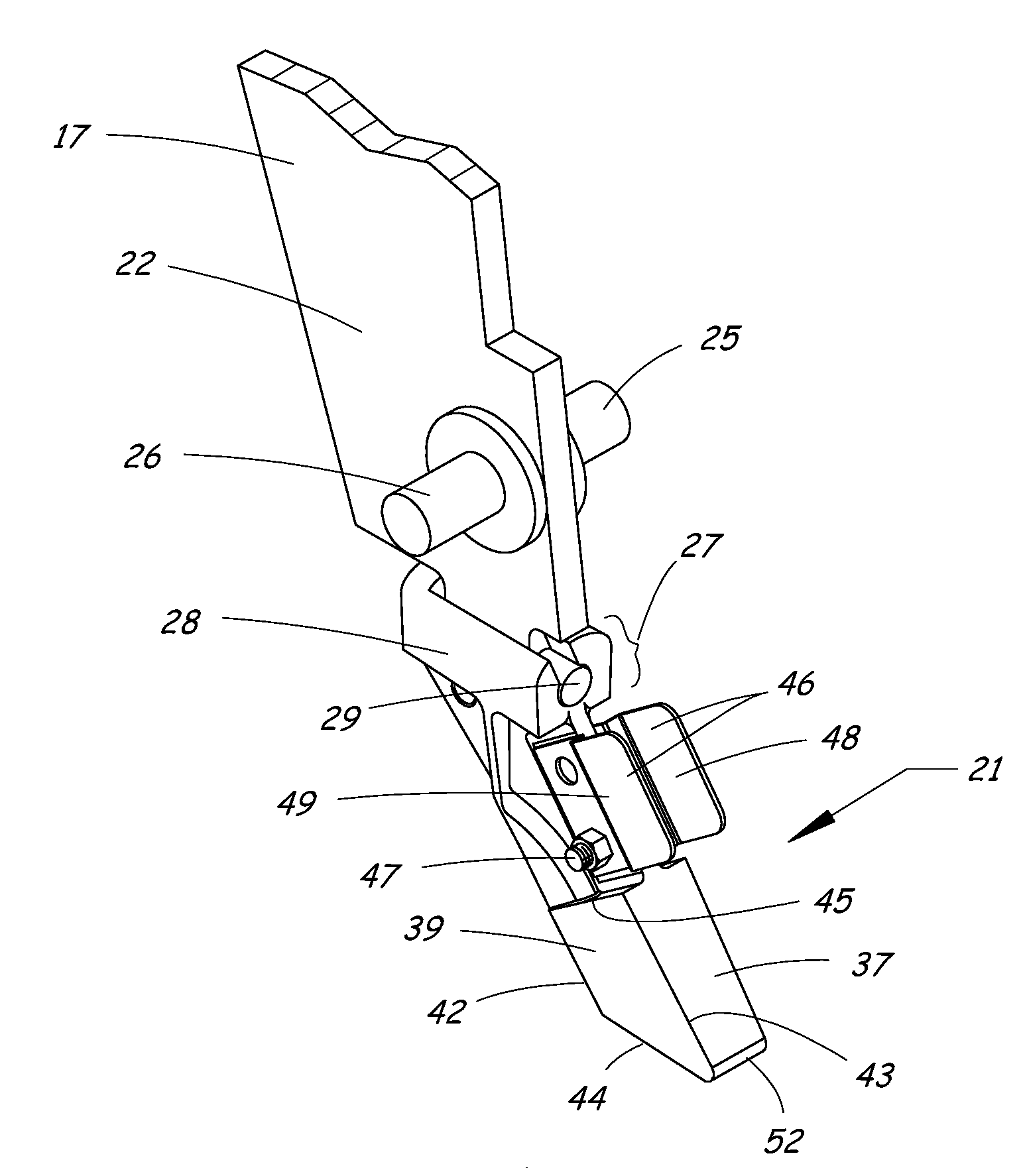

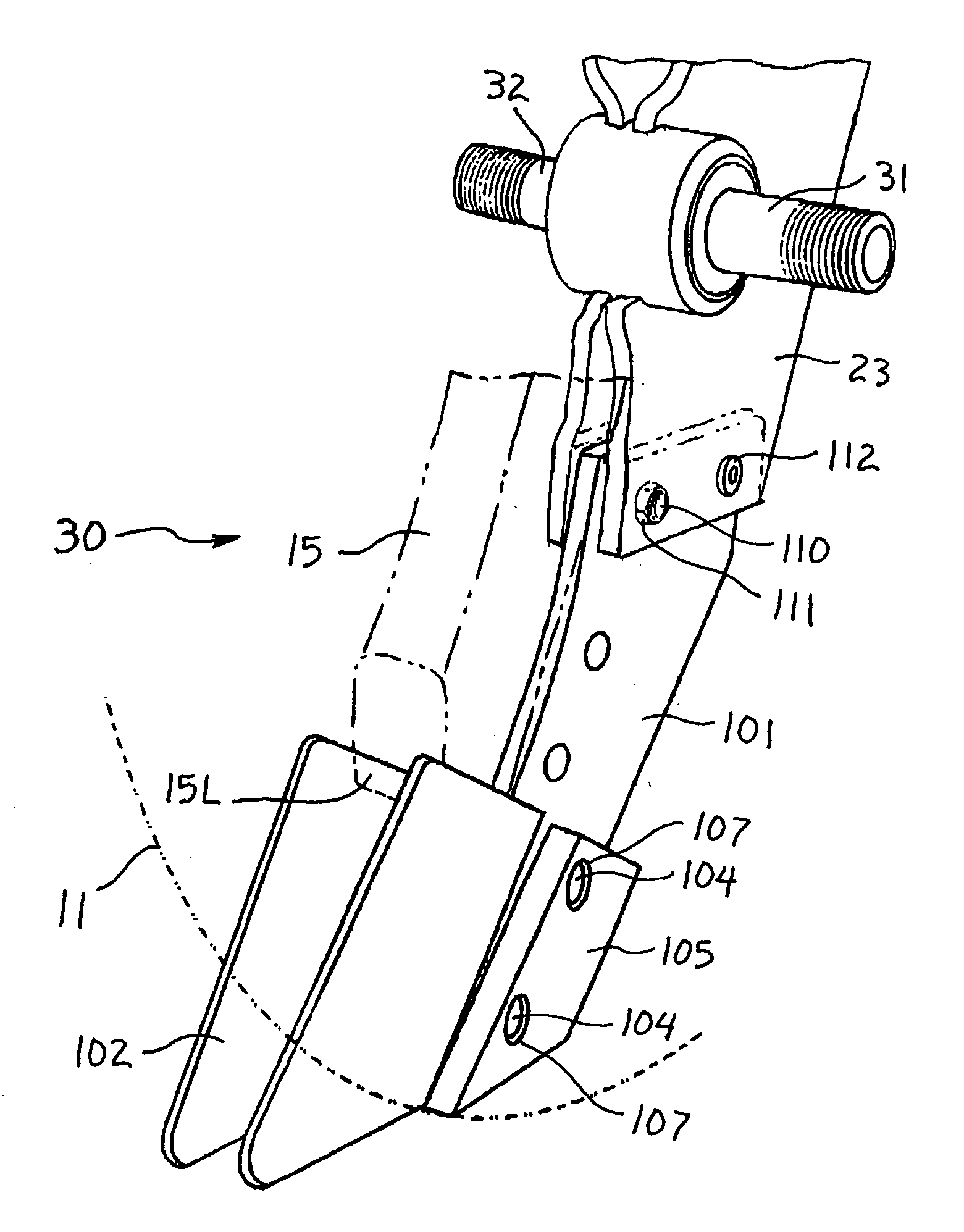

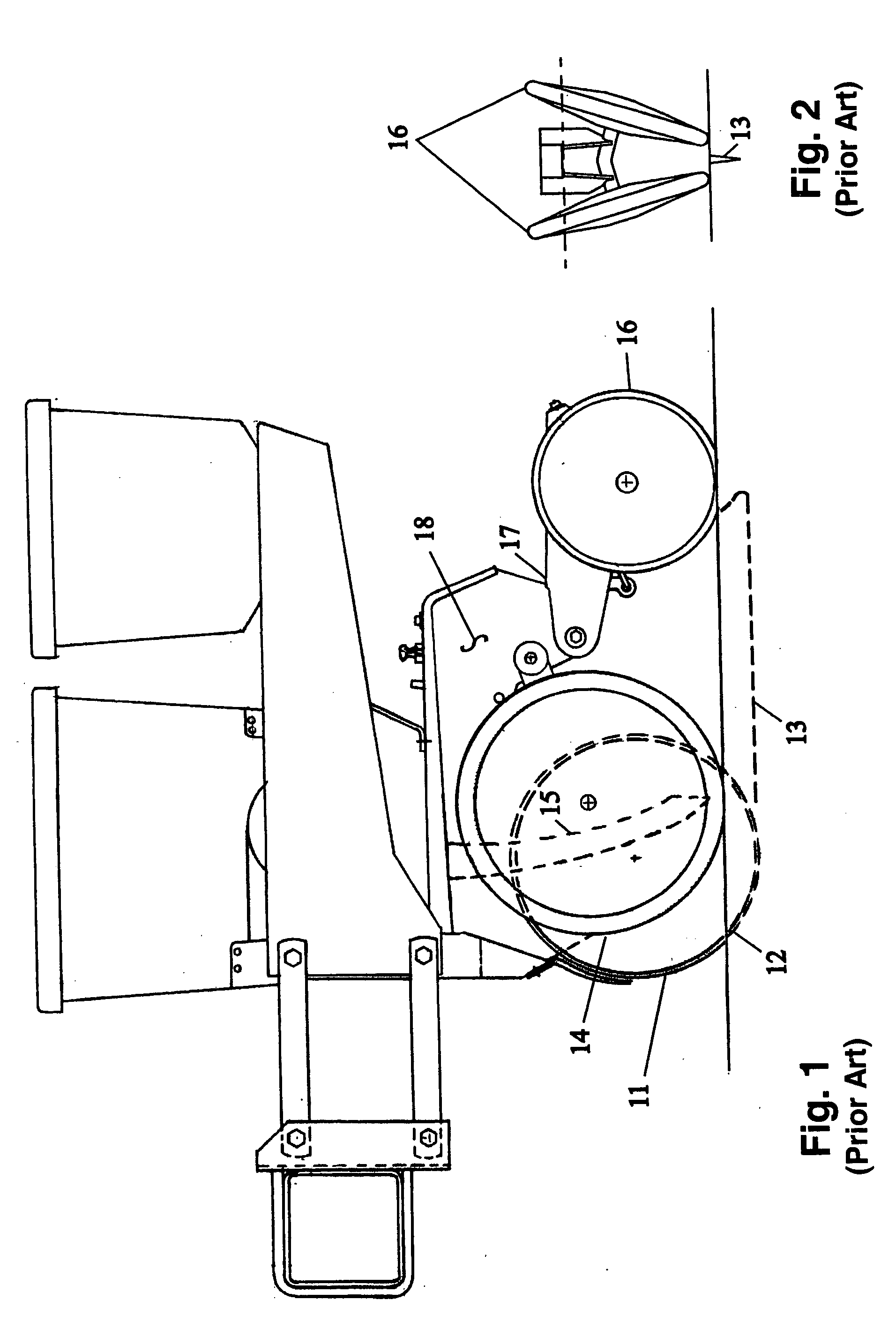

Seed tube guard assembly for agricultural planters

ActiveUS20060032420A1Improve wear lifeAvoid damageFertiliser distributersSowingEngineeringAdemetionine

A seed tube guard assembly for agricultural planters has floating wear plates to improve the wear life of the seed tube guard. The assembly includes a support bracket having an upper end attached to a planter shank assembly and a lower end positioned between a pair of opener disks. A seed tube guide extends rearwardly from the support bracket for receiving a lower end of a seed tube. A pair of dowels are pressed into openings in the support bracket and protrude from the sides thereof. A metal ball is press fit into an opening in the support bracket between the dowels with opposite sides of the metal ball protruding from the respective sides of the support bracket. The floating wear plates are supported by the dowels on the respective sides of the support bracket with the metal ball engaging the wear plates at respective fulcrum points between the dowels.

Owner:COPPERHEAD PLANTER PROD LLC

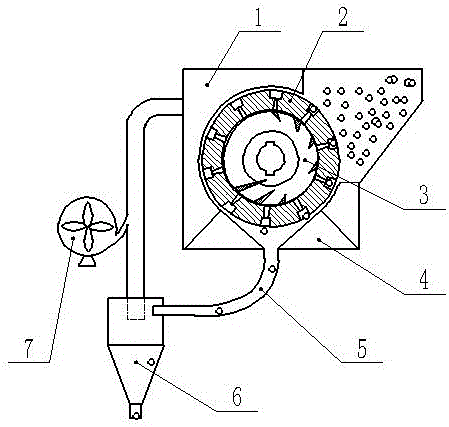

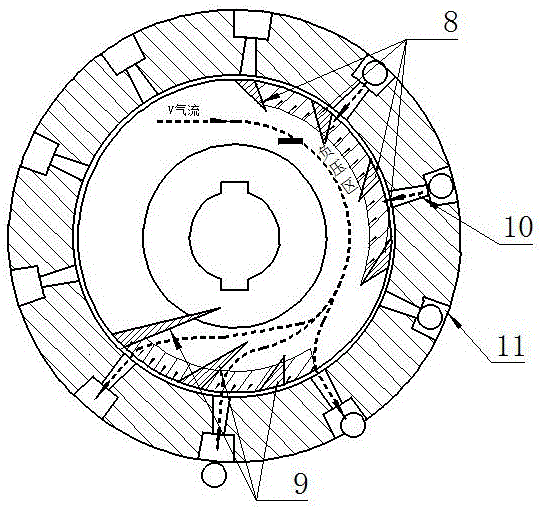

Airflow type seed-metering device

InactiveCN106233895ASimple structureHigh seed filling efficiencySeed depositing seeder partsEngineeringDistributor

The invention provides an airflow type seed-metering device. Seeds are absorbed through negative pressure and airflow blows the seeds to be subjected to seed metering; a seed flow is formed by the seeds in a seed-metering pipe under the action of the airflow, so that collision between the seeds and the seed-metering pipe is reduced; the seeds are stably sowed into seed ditches under the action of a separator, so that the seed sowing precision is increased and the seed sowing quality is improved. The airflow type seed-metering device is mainly composed of an airflow seed-metering device, a compensation draught fan, the separator and the seed-metering pipe; the seed-metering pipe is connected with an outlet the airflow seed-metering device and an inlet of the separator respectively; the draught fan is connected with the outlet of the separator and the inlet of the airflow seed-metering device respectively. The airflow seed-metering device is composed of a shell, a seed disc and an airflow distributor; the airflow generates negative pressure under the action of a forward fan blade in the airflow distributor and is used for filling the seeds; the airflow blows the seeds out of greapel holes under the action of a backward fan blade, so as to carry out seed metering; the airflow and the seeds form the seed flow to enter the seed-metering pipe together; after the seed flow enters the separator, the seeds and the airflow are separated. The device is simple in structure and high in seed filling and metering efficiency; the seed sowing is more accurate and the seed sowing quality is improved.

Owner:NORTHWEST A & F UNIV

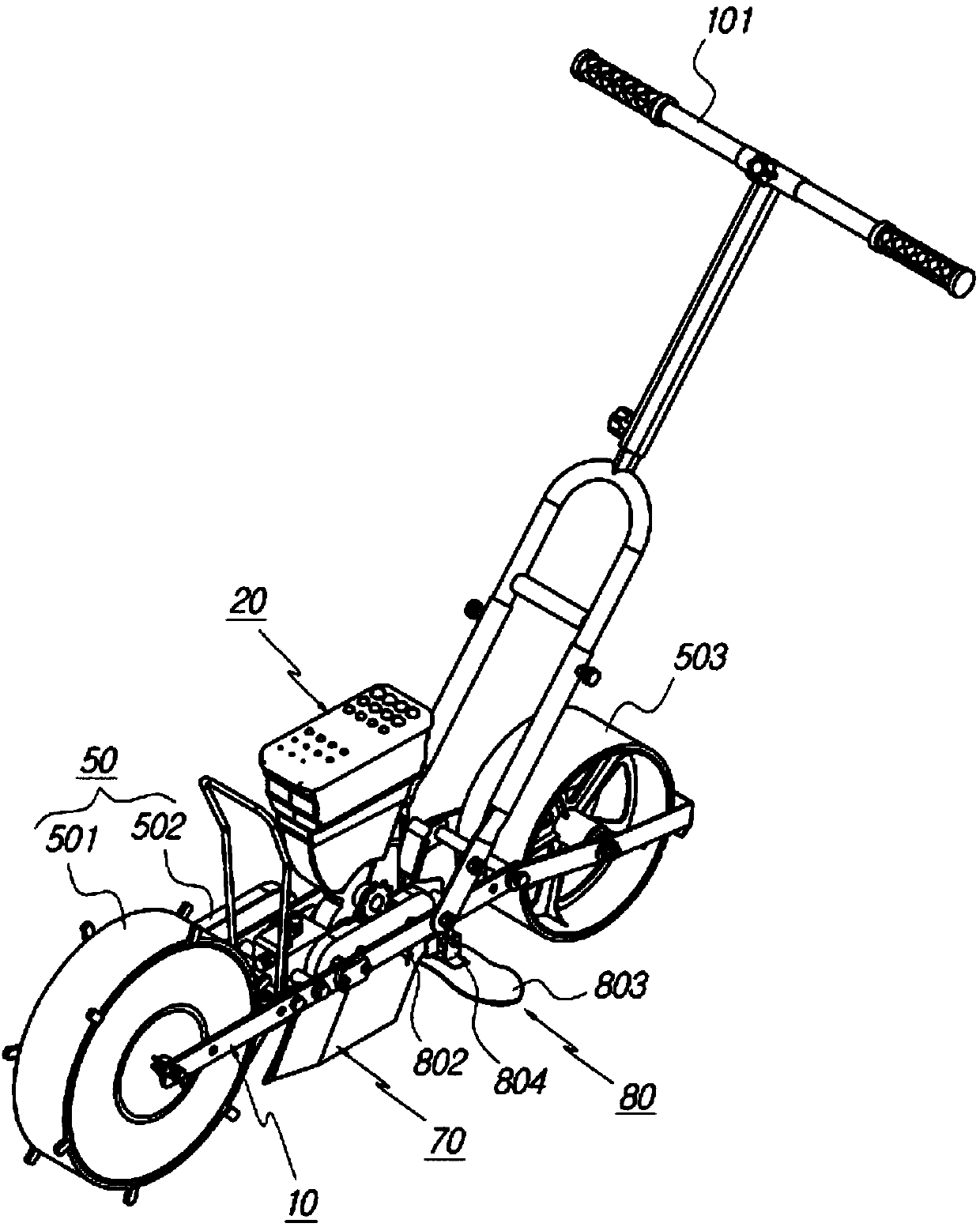

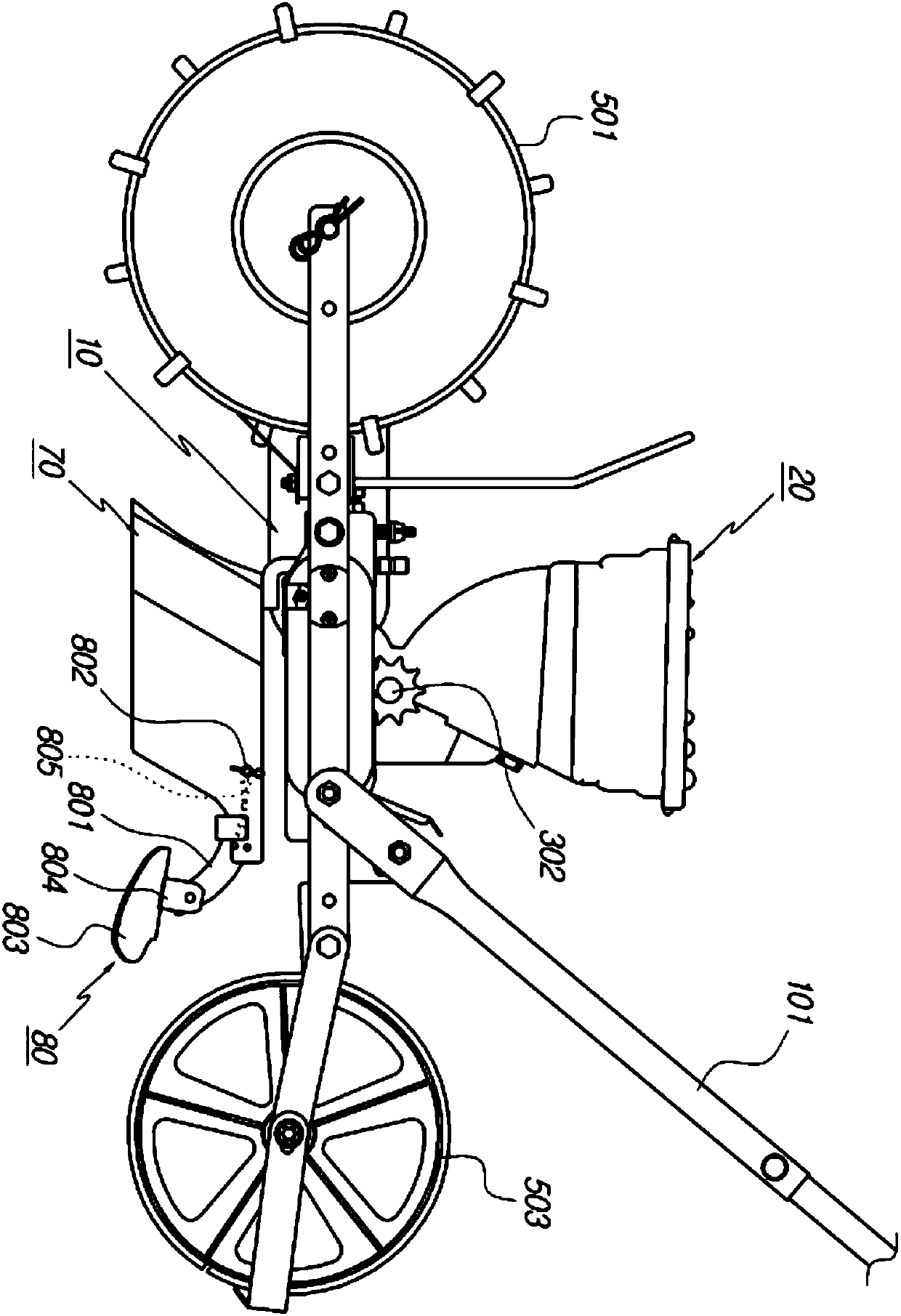

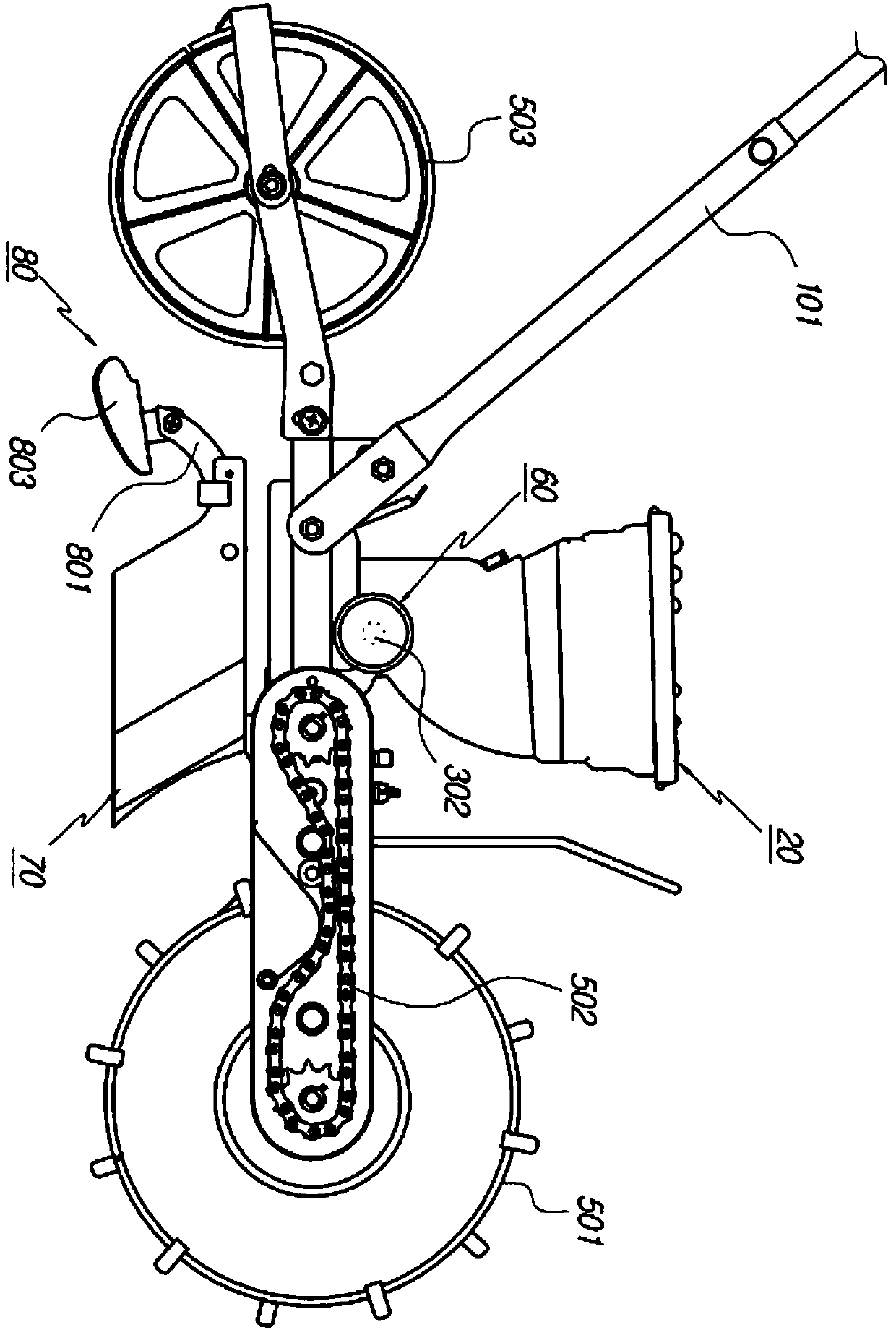

Seeder with electrostatic discharge function

InactiveCN109691274APrevent poor sowingPrevent missing plantsPlantingAgriculture gas emission reductionSeederEngineering

The present invention relates to a seeding machine having a static electricity discharge function. The seeding machine having the static electricity discharge function comprises: a hopper (20) storingseeds for seeding; a seeding roller (30) formed of a conductive synthetic resin having a seed discharging groove (301) in a radial direction on the outer circumference; a notification unit (40) notifying a user of static electricity by sensing the static electricity generated in the seeding roller (30); a driving unit (50) rotating the seeding roller (30); a vibration unit (60) vibrating the seeding roller (30); a plow (70) forming seeding grooves in the direction the seeding machine is moving on a ridge and discharging the static electricity generated in the seeding roller (30) to the groundsurface; and a soil covering and pressing unit (80) covering the seed dropped from the seed discharge groove (301) to the seeding groove with soil by rotation of the seeding roller (30). The seedingmachine enables the user to perform accurate seeding work by preventing a seeding failure due to the static electricity generated during an operation process of the seeding roller (30) and enabling the user to recognize the generation of static electricity by using the visual and audible notification unit at same time.

Owner:(株)张自动化

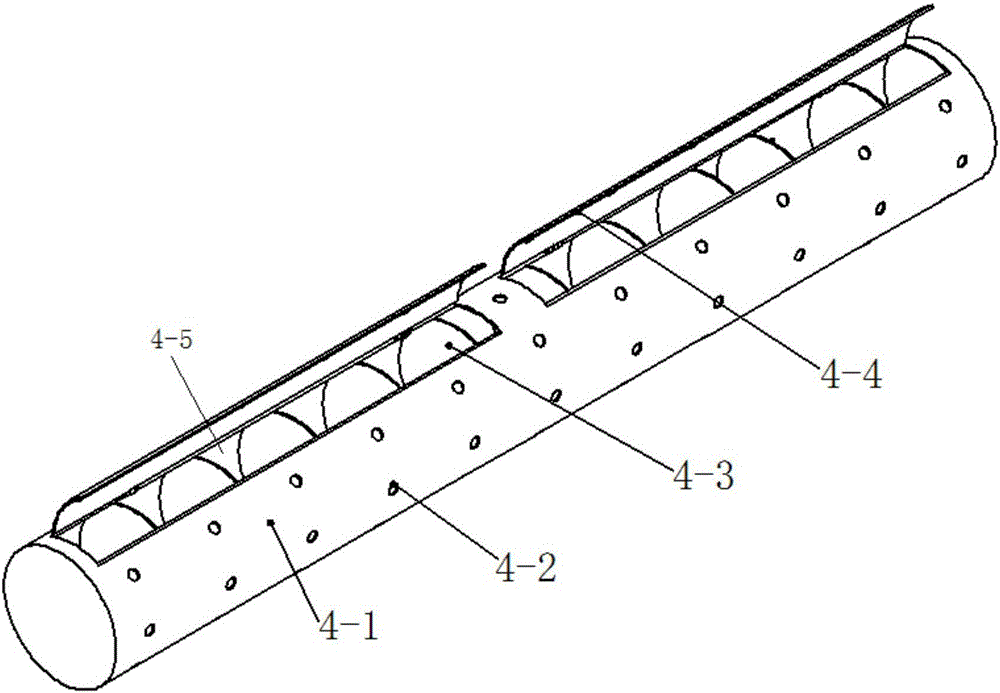

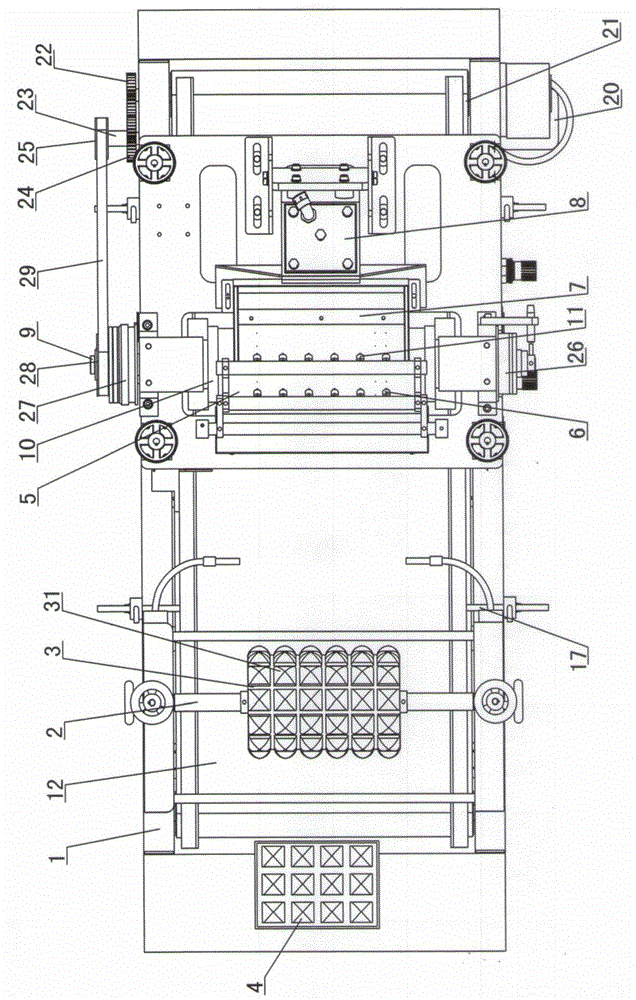

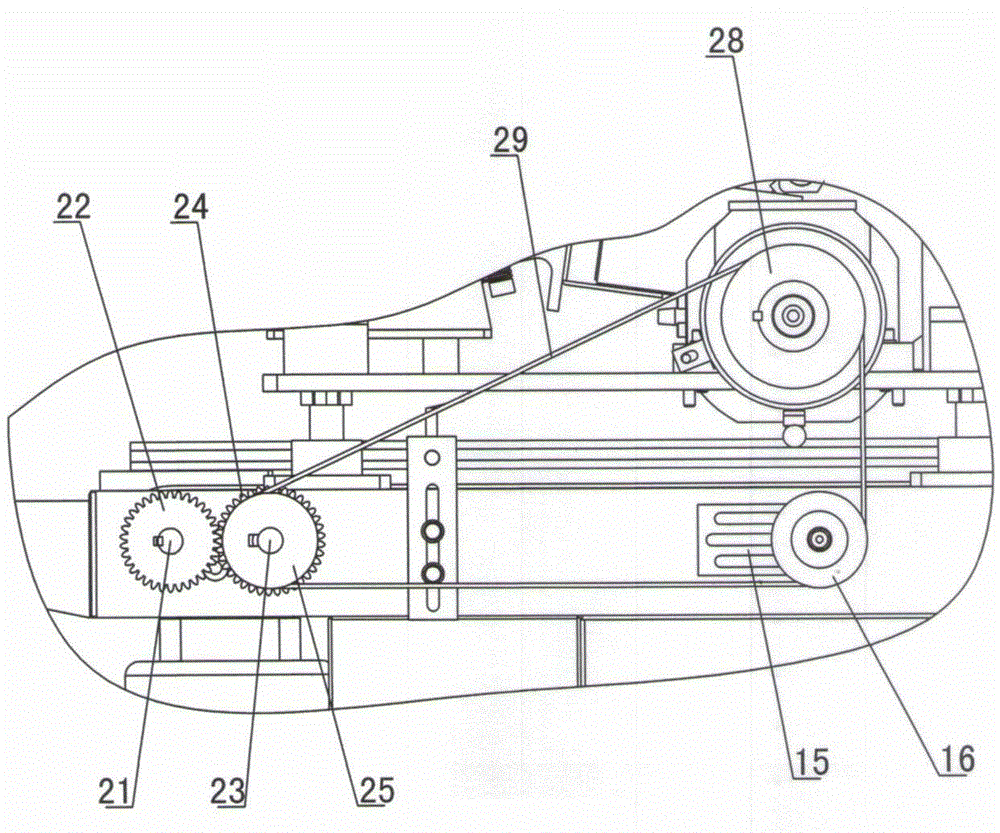

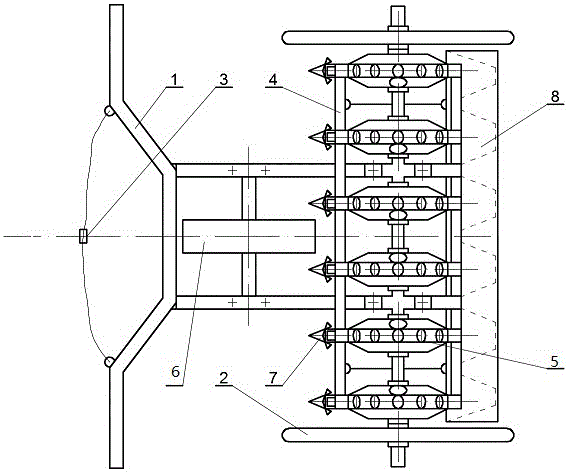

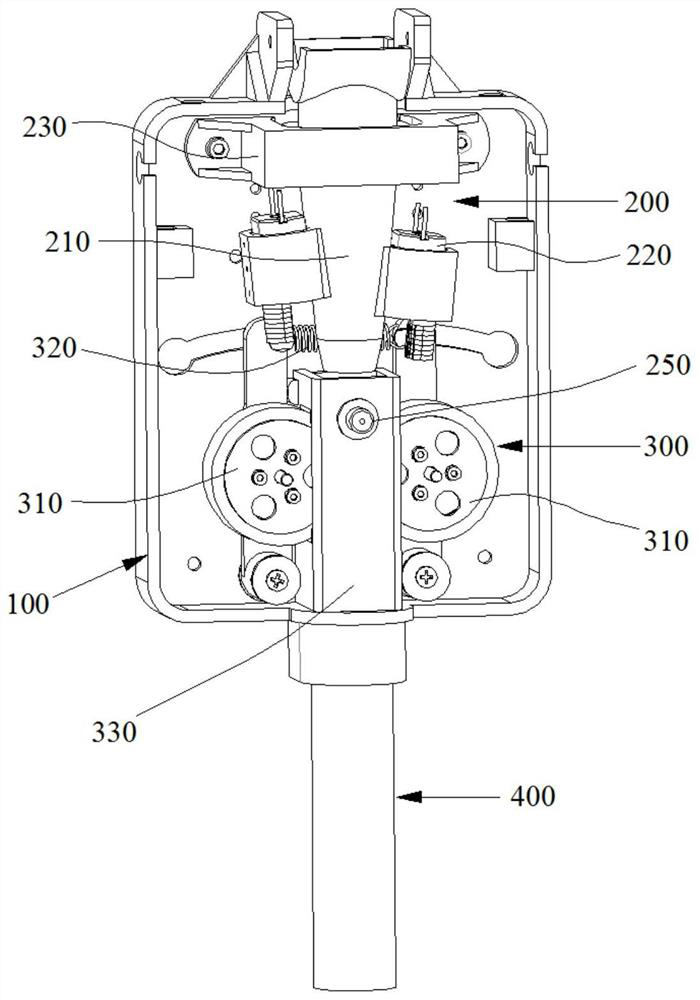

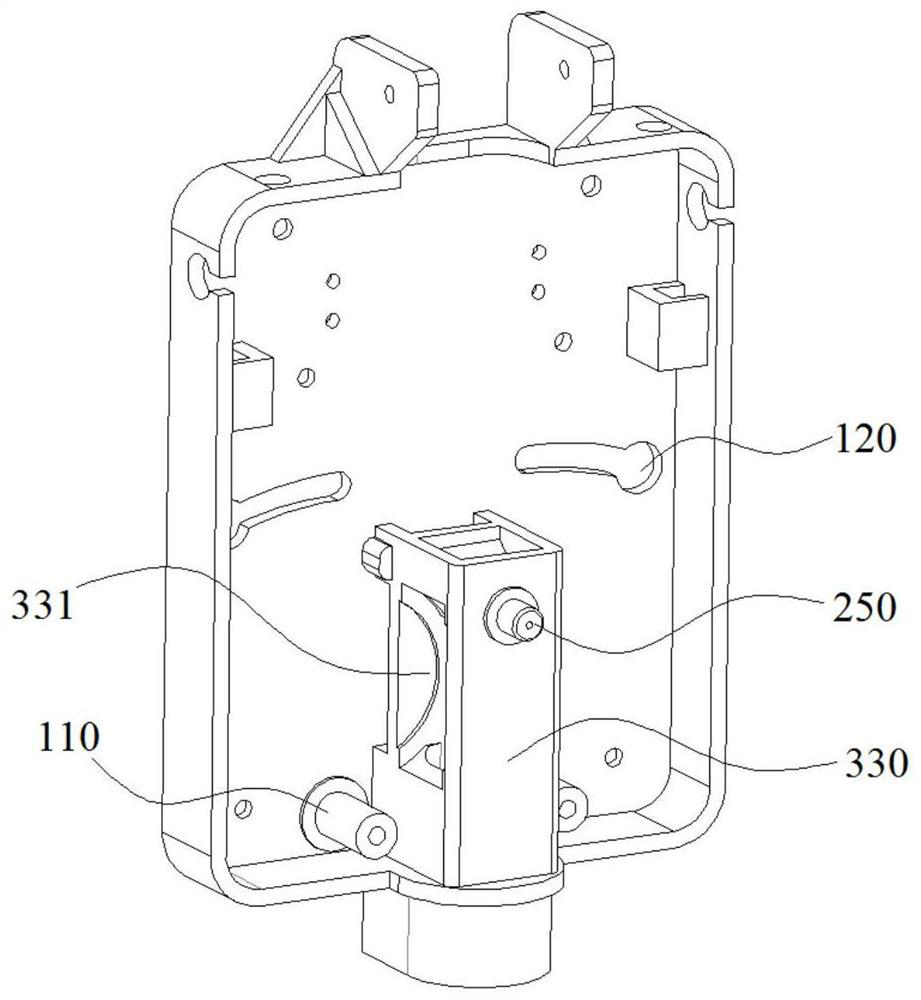

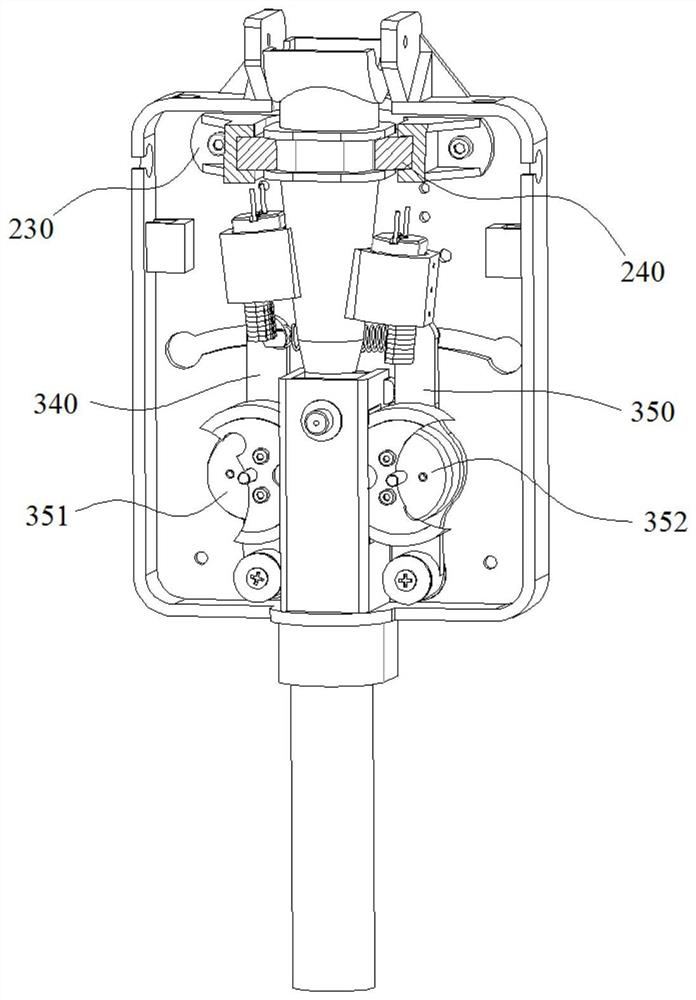

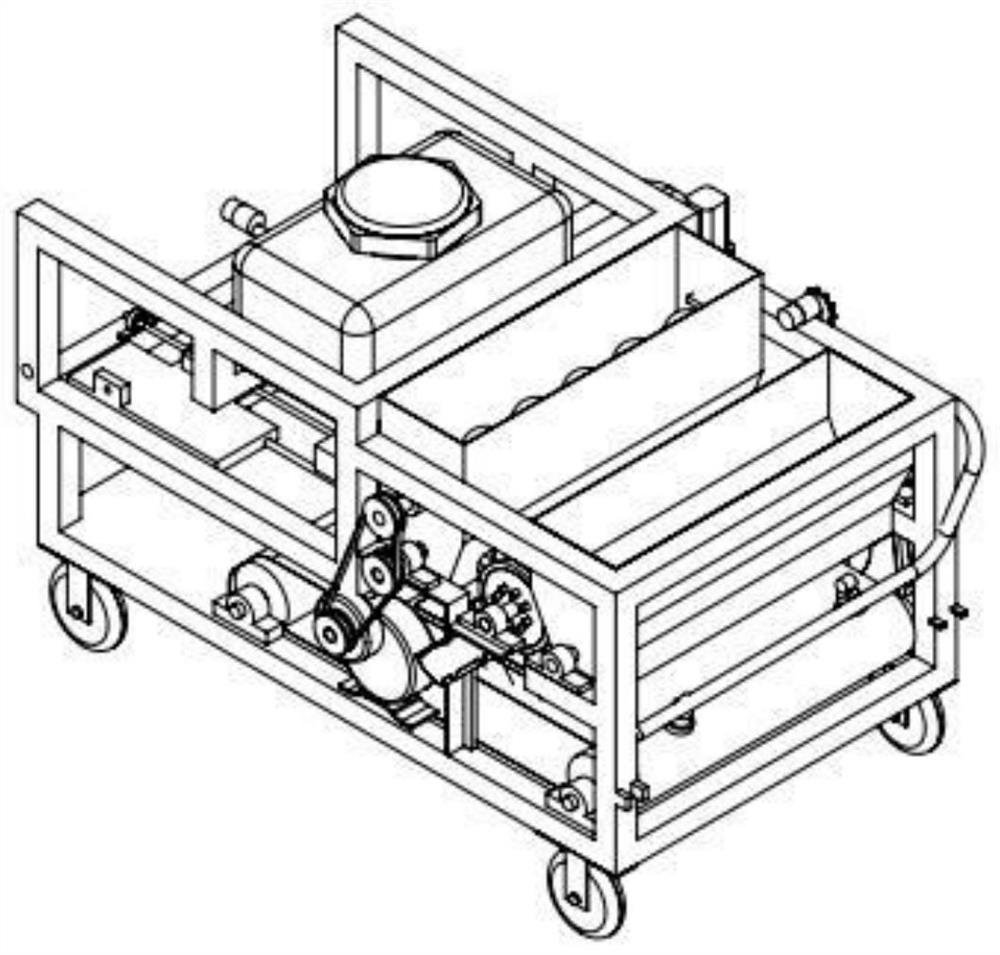

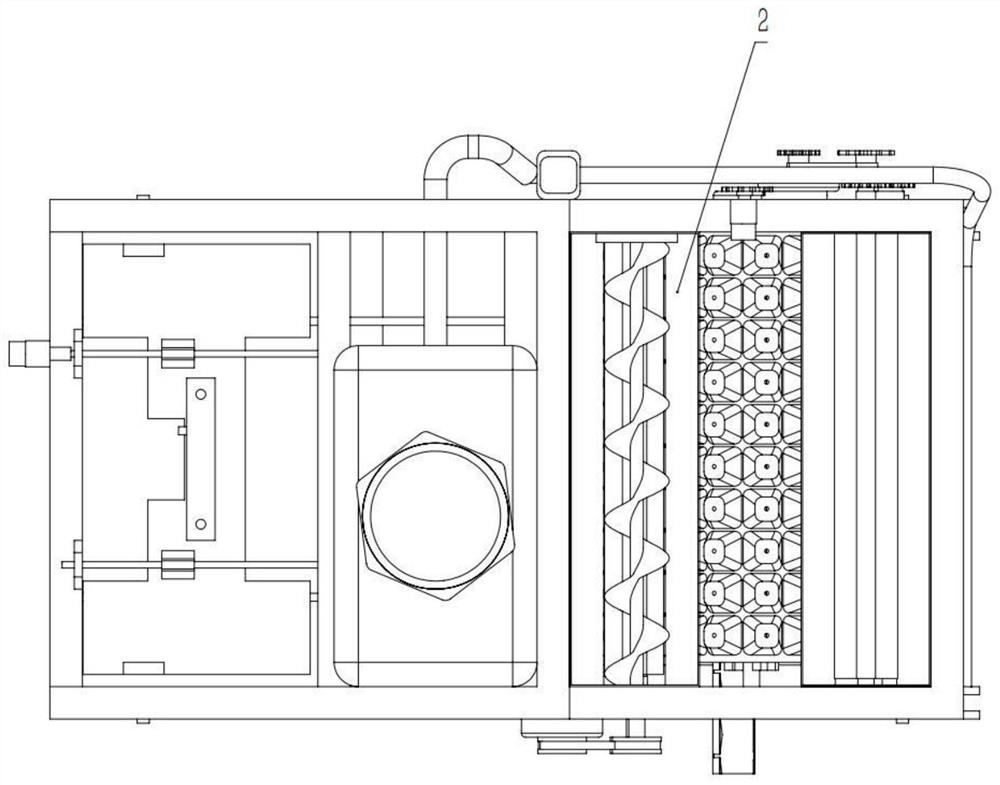

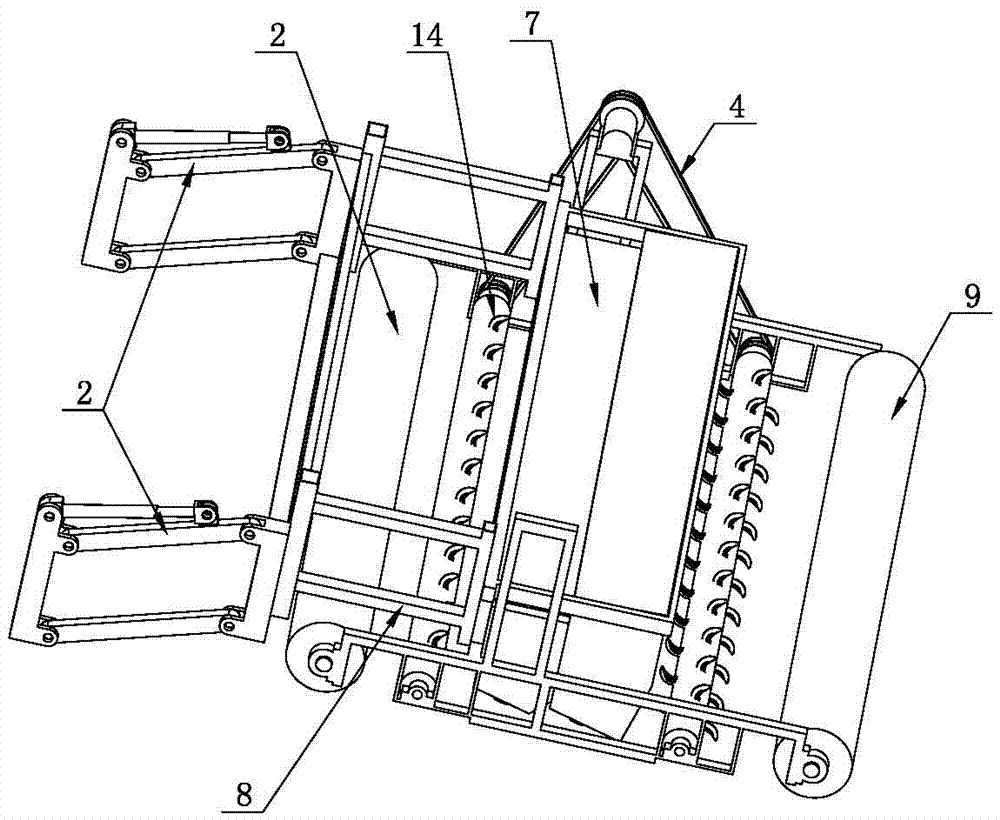

Precision seeder capable of realizing synchronous transmission of conveying and rotary drum

ActiveCN103975671APrecise sowingRegular seed deposition machinesBroadcast seedersAgricultural engineeringNozzle

The invention provides a precision seeder capable of realizing the synchronous transmission of conveying and a rotary drum. The precision seeder comprises a rack, wherein a hole pressing part, a seed clearing part, a seed storage vibration part and a seeding part which are connected to one another through a transmission mechanism are arranged on the rack, a seedling growing tray is arranged on the transmission mechanism, the hole pressing part comprises a hole pressing shaft arranged on the rack, hole pressing wheels are arranged on the hole pressing shaft, hole pressing lugs on the hole pressing wheels are in contact with the seedling growing tray, the seed clearing part comprises a seed clearing and air blowing pipe arranged on the rack, a seed clearing and air blowing nozzle is arranged on the seed clearing and air blowing pipe, the seed storage vibration part comprises a seed storage groove and a seeding vibrator which is arranged on the rack, the seed storage groove is formed in the rack, the seeding part comprises a seeding shaft arranged on the rack, the seeding rotary drum is arranged on the seeding shaft, a seeding hole is formed in the seeding rotary drum, the transmission mechanism comprises a conveyer belt arranged on the rack, and the conveyer belt and the seeding shaft are driven by the synchronous transmission mechanism. The precision seeder is small in size, high in seeding precision, and convenient to install and debug, saves the cost, realizes the synchronous transmission of conveying and seeding and has the good conveying and seeding coordination property.

Owner:杭州赛得林智能装备有限公司

Precise and complete discharge type seed discharge mechanism

InactiveCN108432416AImprove magnetismImprove fill rateSeed depositing seeder partsAgricultural engineeringElectromagnet

The invention provides a precise and complete discharge type seed discharge mechanism, which comprises a seed discharge disk, a seed box and a seed protection plate, wherein the seed box is arranged above the seed discharge disk, the seed protection plate is arranged between the right side of the seed box and the bottom end of the seed discharge disk, the surface of the seed discharge disk is provided with a seed groove and a concave groove, an electromagnet is fixedly connected below the interior of the concave groove, a magnet is movably connected above the electromagnet, a blocking sheet isfixedly connected above the magnet through a movable rod, a pressure varistor is arranged above the blocking sheet, the electromagnet has an N pole above, and the magnet has an N pole above. According to the present invention, the precise and complete discharge type seed discharge mechanism overcomes the disadvantages in the prior art, and has characteristics of reasonable design and compact structure; by arranging the electromagnet, the magnetism of the electromagnet below the seed discharge disk is enhanced when the pressure resistance on the pressure varistor positioned above the seed discharge disk is reduced, and the magnet downward moves through the principle of the repulsion with the same natures, such that the seed in the seed groove can be precisely sowed into the seed hole through the downward movement of the blocking sheet.

Owner:安徽维力拓网络科技有限公司

Precise seed-metering unit with air injection-seed cleaning combined geneva wheel

InactiveCN103843500APrecise sowingProcessing at willSeed depositing seeder partsGear wheelEngineering

The invention relates to a precise seed-metering unit with an air injection-seed cleaning combined geneva wheel in the field of agriculture seeding machinery. The precise seed-metering unit is provided with a precise seed-metering wheel which is arranged in a seed-metering unit housing and can rotate, a plurality of rows of small seed-metering holes are formed in one end of the precise seed-metering wheel, seed-metering slots are uniformly distributed in the periphery of the other end of the precise seed-metering wheel, an air injection pillar is arranged at the lower part of the seed-metering unit housing and is internally tangent with the segment of the small seed-metering holes of the precise seed-metering wheel, air vents are formed in the air injection pillar, the end of the air injection pillar is sealed, air injection holes are arranged downwards, and every one row of small seed-metering holes correspond to one air injection hole. Compared with the background art, the precise seed-metering unit has the advantages that seed pushing by a seeding pushing gear is changed to be high-pressure gas seed cleaning, the size and the number of the precise seed-metering holes are not affected by the seed pushing gear, processing can be carried out randomly, and even smaller seeds can be precisely sown.

Owner:张宇文

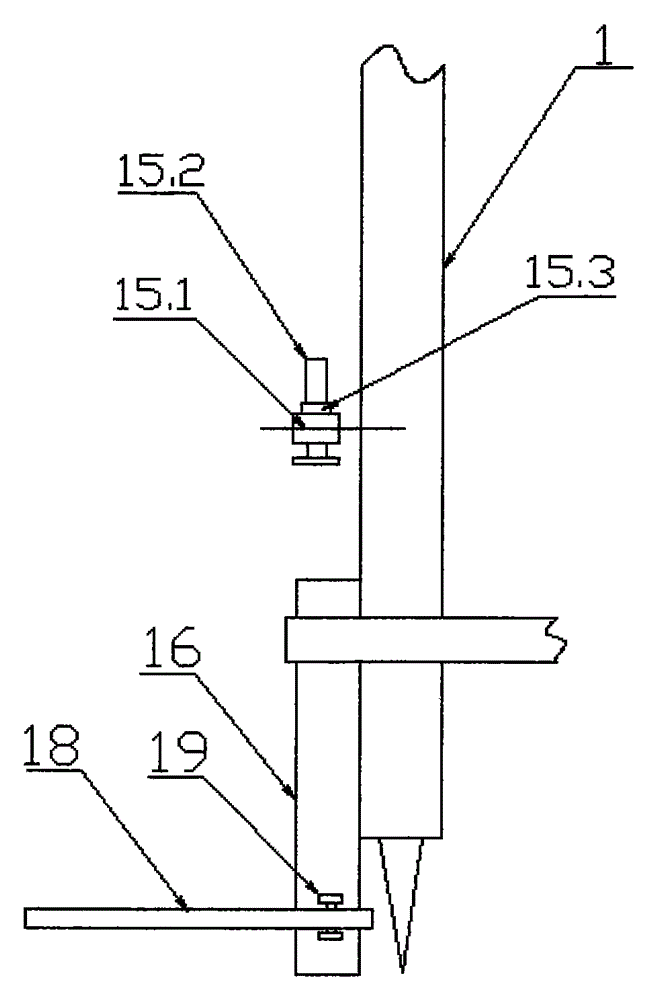

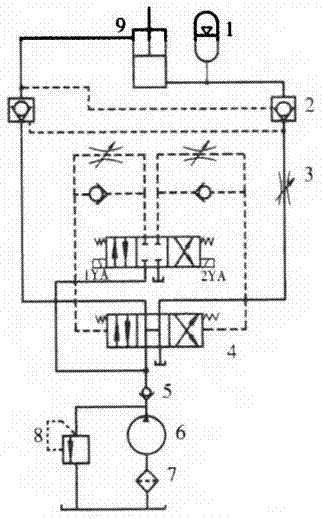

Seeder

ActiveCN104081919AAchieve seedingImprove seeding efficiencyRegular seed deposition machinesSeederSolenoid valve

The invention provides a seeder, and relates to the technical field of machinery. The seeder helps in solving problems such as low seeding efficiency, non-uniform soybean distribution, and soybean wasting of seeding devices in prior arts. The seeder provided by the invention comprises a bottom plate. A seat is arranged on the bottom plate. A traveling mechanism is arranged on the lower part of the bottom plate. A storage hopper used for storing seeds is fixed on the bottom plate. A feeding pipe is fixed on the lower part of the storage hopper. The lower end of the feeding pipe penetrates through the bottom plate. A solenoid valve used for communicating or blocking the feeding pipe and the storage hopper is arranged between the feeding pipe and the storage hopper. A dibbling pipe is arranged outside the feeding pipe. The lower part of the dibbling pipe is provided with a tip. The upper part of the dibbling pipe is connected with an elevation positioning mechanism which can drive the dibbling pipe to elevate up and down and can position the dibbling pipe. The seeder provided by the invention has the advantages of high seeding efficiency and low labor intensity.

Owner:孔祥金

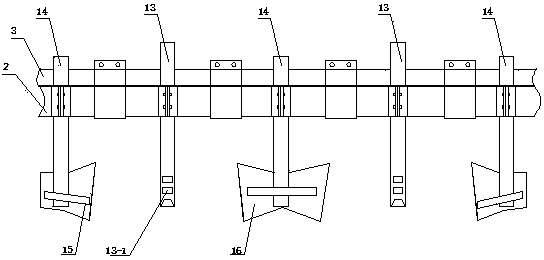

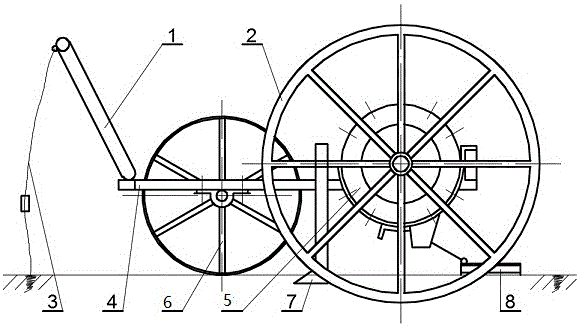

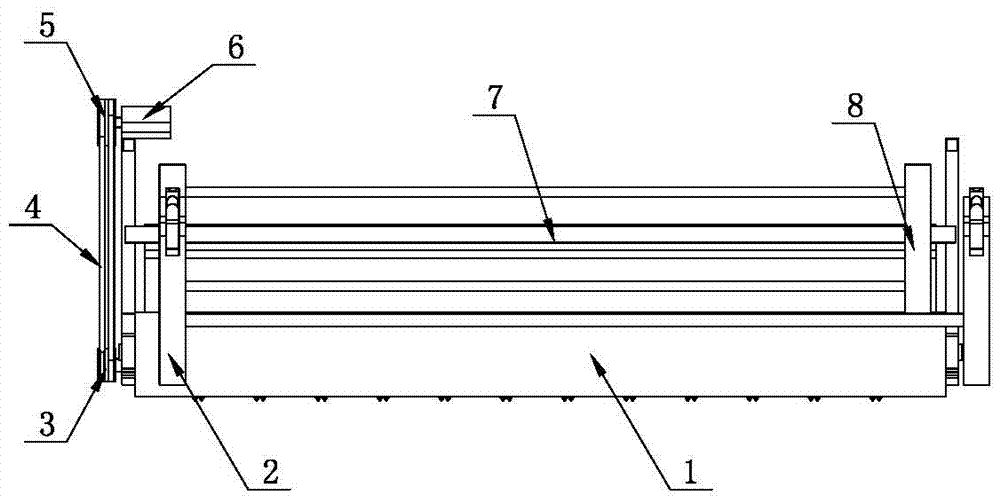

Sowing machine for dry land

InactiveCN105850302AAccurate seeding operationGood effectRegular seed deposition machinesDrive shaftTraction frame

The invention provides a sowing machine for dry land. The sowing machine comprises a traction frame, driving land wheels, a rack, roller type seeder units, a ditching depth wheel, furrow openers and covering devices, wherein the traction frame is arranged at the front end of the rack; the ditching depth wheel and the plurality of roller type seeder units are respectively arranged at the front and the back of the rack; the furrow openers and the covering devices are respectively arranged at the fronts and the backs of all the roller type seeder units in a way of one-to-one correspondence; the roller type seeder units are fixed on a transmission shaft; the transmission shaft is fixed on the rack; the two ends of the transmission shaft are respectively provided with the driving land wheel. The sowing machine for the dry land is simple in mechanical structure and convenient to use, is capable of adjusting plant spacing and accurately sowing so as to save seeds, and is rapid in sowing speed, uniform in sowing and good in sowing effect.

Owner:XIANNING AGRI ACADEMY OF SCI

Garden landscape lawn construction and planting method

InactiveCN110313351AWell mixedPromote germinationGrassland seedingHops/wine cultivationBiologyLiving environment

The invention discloses a garden landscape lawn construction and planting method and relates to the technical field of garden landscape. The method specifically comprises the following step of selection and arrangement of a site, wherein the area of the selected site is measured first, the seed quantity is calculated, impurities, stones, dead plant branches, building materials and the like in thesite are removed, perennial weeds are thoroughly removed, and surface soil is added in the places with poor soil conditions. Through the garden landscape lawn construction and planting method, the problems of long construction and planting cycle, nonuniform lawn growth and poor drought resistance of lawns in a construction and planting process of the lawns can be well solved. By improving a previous lawn construction and planting method, the construction and planting cycle is shortened, and the growth uniformity degree of a lawn is improved; the purpose of improving the living environment of microorganisms in soil in a lawn turning process to promote the growth of the lawn is achieved, and the lawn grows more uniformly by improving a lawn sowing mode.

Owner:ANHUI YILING MOLD DESIGN CO LTD

Dot-jet type seed metering method and device

ActiveCN112693614AGuaranteed real-timeImprove efficiencyAircraft componentsSeed depositing seeder partsAgricultural engineeringUncrewed vehicle

The invention relates to a dot-jet type seed metering method. The method comprises the following steps: S1, calibrating parameters: calibrating and storing dot-jet type seed metering control parameters; S2, vibrating and queuing to discharge seeds: filling seeds into a conical cylinder through a seed adding port, controlling the conical cylinder to vibrate, enabling the seeds to flow under the action of vibration, and discharging and falling from a seed discharging head; S3, friction acceleration: enabling two sides of the fallen seeds to generate friction force in the same direction as a preset ejection direction, so that the seeds are discharged at a high speed at an acceleration corresponding to the friction force; and S4, direction adjustment: guiding the direction of the seeds discharged at a high speed, so that the seeds are accurately shot to a target position. According to the method, seeds can be discharged at a high speed, the influence of an environment wind field is reduced, the unmanned aerial vehicle can still achieve accurate seeding while keeping a high flight height, meanwhile, arching and blocking of the seeds in the seed discharging process can be avoided, the seeds are queued at a high speed, the seeding efficiency is improved, and the method can be used for seeding operation and seeding operation. And the device can also be used for single-particle rapid discharging operation of other particle materials. The invention also relates to a dot-jet type seed metering device.

Owner:SOUTH CHINA AGRI UNIV +1

Precise seed-sowing device for pneumatic seeder

InactiveCN111480426AImprove practicalityGuaranteed tightnessSeed depositing seeder partsSeederAgricultural engineering

The invention discloses a precise seed-sowing device for a pneumatic seeder. The precise seed-sowing device comprises a sowing tank, wherein a seed feeding tank is fixedly connected to the top of thesowing tank, a sowing plate communicates with the right side of the seed feeding tank, and the top of the sowing tank communicates with the bottom of the seed feeding tank. The invention relates to the technical field of seeders. According to the precise seed-sowing device for the pneumatic seeder, a vacuum generator is started to control a first communication pipeline to generate a negative pressure in a seed feeding roll, and seeds are adsorbed in concave holes; when the seed feeding roll rotates, the concave holes in the surface of the seed feeding roll continuously adsorb the seeds in thesowing tank, the adsorbed seeds are extruded by virtue of an elastic extrusion pad and slide into a guiding trough, then a second communication pipeline communicating with the vacuum generator blows ablowing hole along an air-guiding pipeline all the time, the seeds are blown into a sowing pipeline in the sowing plate through the blowing hole and can be quantitatively sowed rapidly and continuously, and accurate quantification is realized, so that errors and a blocking condition are avoided.

Owner:杨贵娟

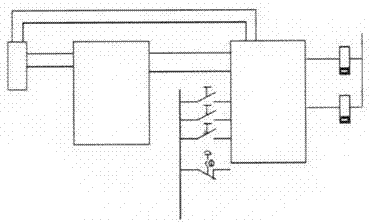

Automatic control system for height of cutting table of combine-harvester

InactiveCN106856807AAvoid economic lossAvoid wastingMowersServomotorsAutomatic controlControl system

The invention relates to an automatic control system for the height of a cutting table of a combine-harvester. A hydraulic lifting device of the cutting table of the harvester is modified by a sensor, the sensor mounted on the cutting table of the harvester can accurately measure the distance between the cutting table and a road surface on which the harvester runs, by a PLD working principle, a logical program is edited, detected data are collected, analyzed and processed, commands are send out to the hydraulic lifting system of the cutting table of the harvester, and therefore, the cutting table ascends and descends automatically; the distance between the cutting table and the road surface on which the harvester runs is proper, the cutting table is prevented from colliding with a rugged road surface in a running or harvesting process, and unnecessary economic loss is avoided; meanwhile, the harvesting efficiency can be improved; accurate harvesting in the next season is facilitated; seed sowing is accurate; and waste is avoided. Theory and practice support is provided for development and modification of the cutting table of the harvester.

Owner:魏莹

Automatic film-breaking type electric control seeding machine and method for peanuts

InactiveCN113785673ARealize automatic film breakPrecision fertilizationSpadesClimate change adaptationSeederAgricultural engineering

The invention relates to an automatic film-breaking type electric control seeding machine and method for peanuts, and belongs to the technical field of agricultural machinery type peanut seeding machinery. According to the technical scheme, the seeding machine is lifted upwards through a suspension lifting system of a tractor, a film cutting device mounting handle (33) fixed to the rear portion of a rack (8) is lifted accordingly, the end, connected with a connecting shaft (41), of a film cutting knife support (36) is lifted, a film nailing knife (37) and a film breaking knife (38) at the other end of the film cutting knife support (36) fall down, the film nailing knife (37) presses a mulching film, and the film breaking knife (38) falls down to automatically cut off the mulching film; and after the film is broken, the suspension lifting system of the tractor returns to the normal transportation height, so that the film breaking knife (38) is lifted to leave the ground. The automatic film-breaking type electric control seeding machine has the advantages of achieving automatic film breaking after peanut planting operation is completed, and is convenient and practicable; and electric control fertilization and seeding are achieved, precise fertilization and seeding are achieved, fertilizer leakage and seed leakage are prevented, labor is saved, and the structure is compact.

Owner:杨 志锋

Plug seedling all-in-one machine

PendingCN112772223ASowing is easy to controlTo achieve an organic combinationPlantingWatering devicesSeederSuction force

The invention relates to a plug seedling all-in-one machine which comprises a plug carrying mechanism, a nutrient soil placing mechanism, a compacting and sowing mechanism, a soil covering mechanism, a water spraying mechanism, a transmission mechanism and a rack. The plug carrying mechanism is arranged on the front portion of the rack, and the nutrient soil placing mechanism is arranged in the middle of the rack; and the sowing mechanism, the soil covering mechanism and the water spraying mechanism are sequentially arranged behind the nutrient soil placing mechanism, a conveying belt is arranged below the nutrient soil placing mechanism, the sowing mechanism and the soil covering mechanism, and the nutrient soil placing mechanism, the sowing mechanism and the soil covering mechanism are connected through the transmission mechanism. The air suction drum type compacting and sowing mechanism is adopted, a sowing mechanism and a compaction mechanism are combined into a whole, and sowing is easier to control through suction force provided by an air pump. The plug seedling all-in-one machine integrates plug dividing, soil filling, compaction, sowing, soil covering and irrigation, is low in manufacturing cost, high in safety coefficient, convenient to maintain, more labor-saving in operation, capable of achieving precise sowing, beneficial to improving the working efficiency and wide in application prospect.

Owner:BINZHOU UNIV

Agricultural particle sowing device and counting method

PendingCN113068483AFacilitate Personalized AnalysisAchieve countCounting objects on conveyorsIndividual particle analysisSeederAgricultural science

The invention belongs to the technical field of agricultural equipment, and particularly discloses an agricultural particle sowing device and a counting method. The agricultural particle sowing device comprises a plurality of sowing mechanisms, each sowing mechanism comprises a shell, a storage bin and a sowing unit are arranged in each shell in an up-down corresponding mode, each storage bin is provided with a discharging hopper, and a discharging opening is formed in the bottom of each discharging hopper; each sowing unit comprises a baffle plate, a material taking plate and a sowing bin which are sequentially arranged from top to bottom, and material taking holes are correspondingly formed in the baffle plates and the material taking plates; each sowing bin is composed of a material leaking plate and a material taking hopper, and a material leaking opening is further formed in each material leaking plate; and the baffles are connected with first driving parts, and the material taking plates are connected with second driving parts. Through the structural design, the agricultural particulate matter sowing process is completed through a mechanical structure, accurate sowing can be achieved, one particulate matter is sown each time, and sowing nonuniformity is avoided.

Owner:AIR FORCE UNIV PLA

Double roller supported device for ditch digging, sowing and soil covering

ActiveCN107873183ASolve technical problems that cannot be accurately sownPrecise sowingPlantingFurrow making/coveringAgricultural engineeringAgricultural machinery

The invention discloses a double roller supported device for ditch digging, sowing and soil covering in the technical field of agricultural machinery. The double roller supported device comprises a lifting sowing frame, wherein a sowing box is fixedly connected with the sowing frame, a plurality of seed discharging devices are arranged at the bottom of the sowing box, and seed outlets of the seeddischarging devices are formed towards the ground; a support roller and a support pressing roller are rotatably connected to the sowing frame, the sowing box is arranged between the support roller andthe support pressing roller, and a ditch digging shaft is rotatably connected with the part, between the sowing box and the support roller, of the sowing frame; a plurality of ditch digging knife sets are arranged on the ditch digging shaft, at least one ditch digging knife is arranged in each radial direction of the ditch digging shaft, and a soil covering shaft is rotatably connected with the part, between the sowing box and the support pressing roller, of the sowing frame; a plurality of soil covering knives are arranged on the soil covering shaft. According to the double roller supporteddevice for ditch digging, sowing and soil covering, accurate seed falling can be achieved, and deep sowing is ensured.

Owner:NANJING WOYANG MACHINERY TECH

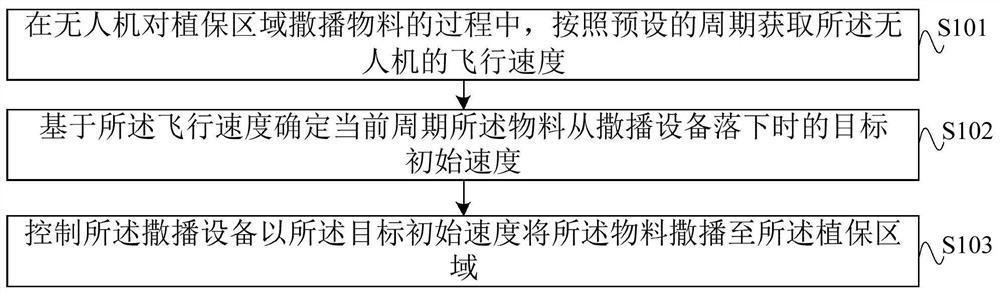

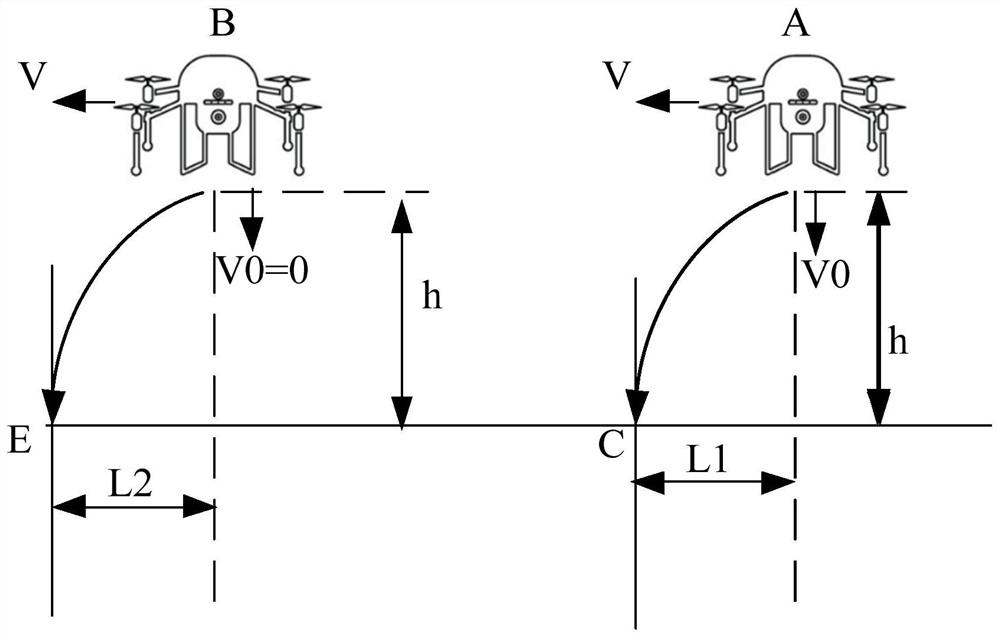

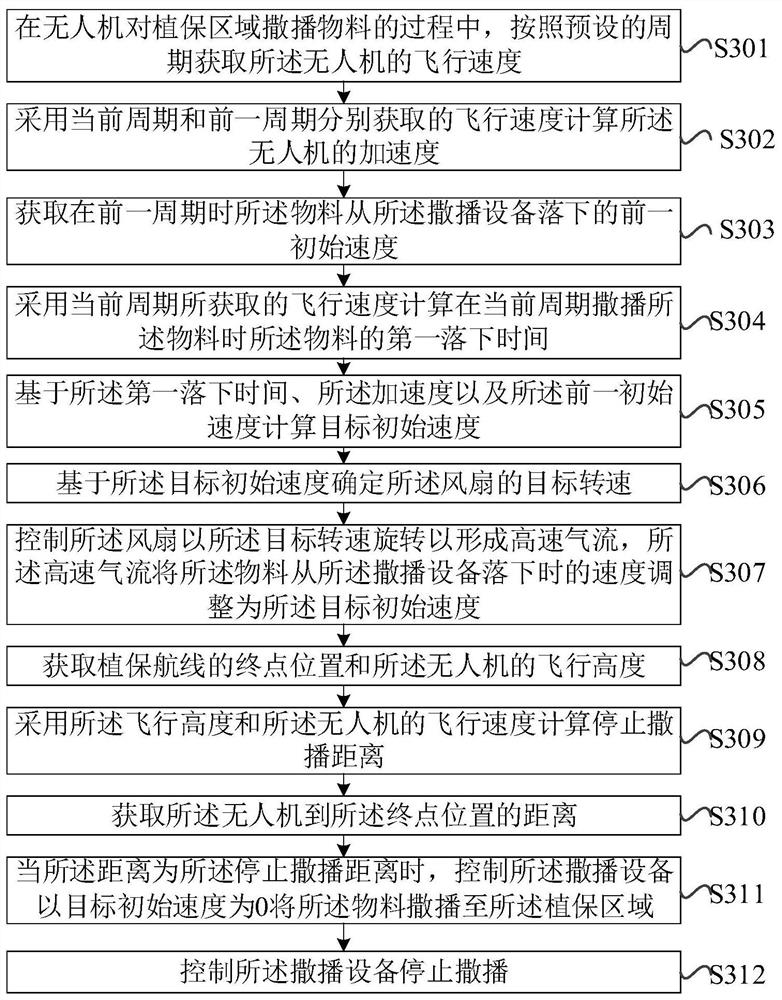

Broadcast sowing control method, broadcast sowing control device, unmanned aerial vehicle and storage medium

PendingCN112859906AAvoid uneven material spreadingPrecision spreadingPosition/course control in three dimensionsFlight heightSowing

The embodiment of the invention discloses a broadcast sowing control method, a broadcast sowing control device, an unmanned aerial vehicle and a storage medium. The broadcast sowing control method is applied to an unmanned aerial vehicle mounted with broadcast sowing equipment. The broadcast sowing control method comprises the steps that: the flight speed of the unmanned aerial vehicle is acquired according to a preset period in the process that the unmanned aerial vehicle broadcasts materials in a plant protection area; based on the flight speed, a target initial speed when the material falls from the broadcast sowing equipment in the current period is determined; and the broadcast sowing equipment is controlled to broadcast the materials to the plant protection area at the target initial speed. The initial speed when the material falls is determined according to the flight speed, and the falling time of the materials is determined according to the initial speed under the condition that the flight height is constant, so that the horizontal movement distance of the materials can be adjusted according to the falling time, and the horizontal movement distance is matched with the horizontal movement distance of the unmanned aerial vehicle, so that the materials are broadcasted to accurate positions, the problem that the materials are broadcasted unevenly due to changes of the flight speed is avoided, accurate broadcast of the materials is achieved, and the even broadcasting effect can be achieved.

Owner:GUANGZHOU XAIRCRAFT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com