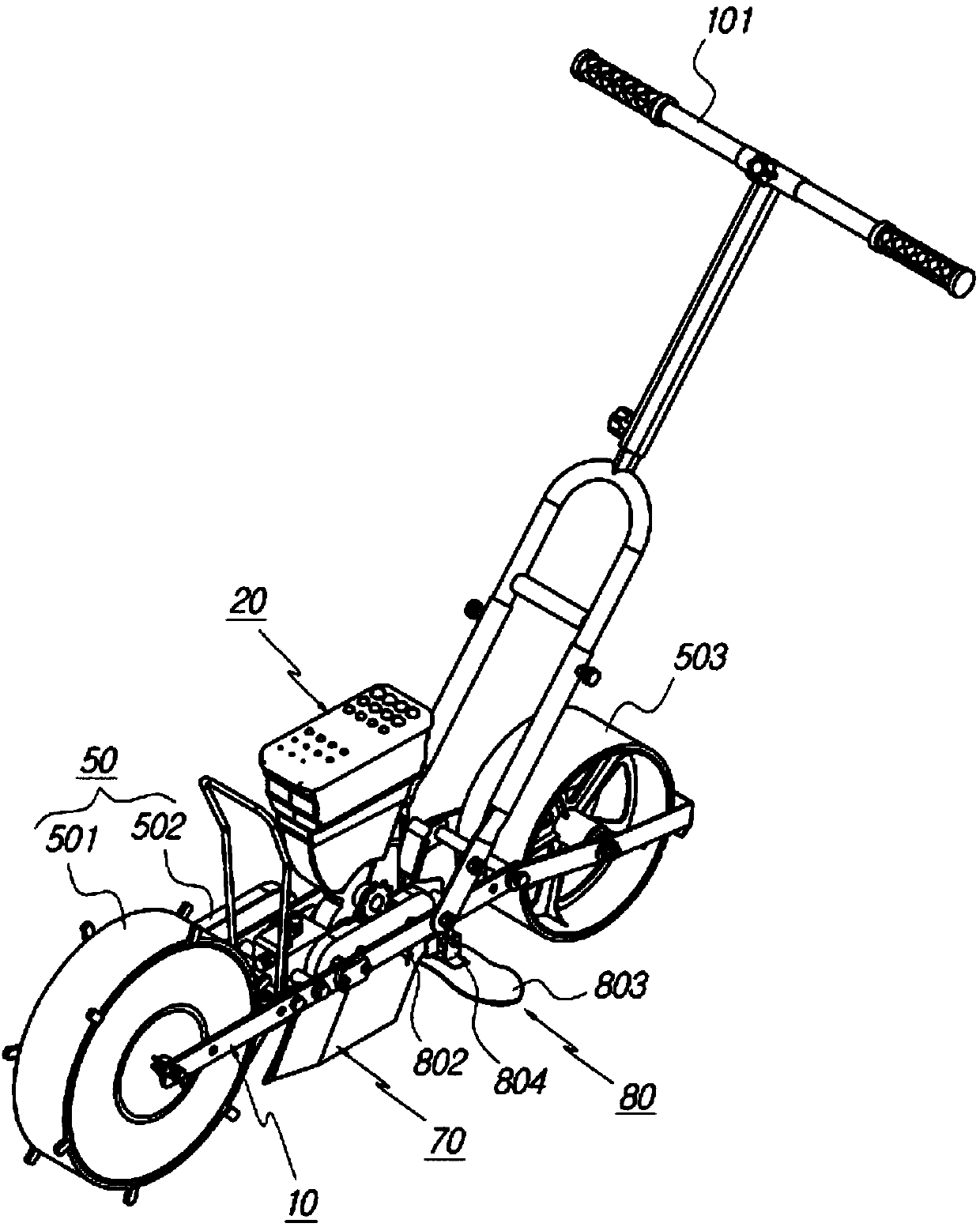

Seeder with electrostatic discharge function

An electrostatic discharge and seeder technology, applied in the directions of sowing seeders, seeder parts, and interval-type quantitative seeding machines, can solve the problems of aggravating static electricity, poor seeding, material deformation, etc., to prevent missing plants and prevent poor sowing. , the effect of accurate sowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

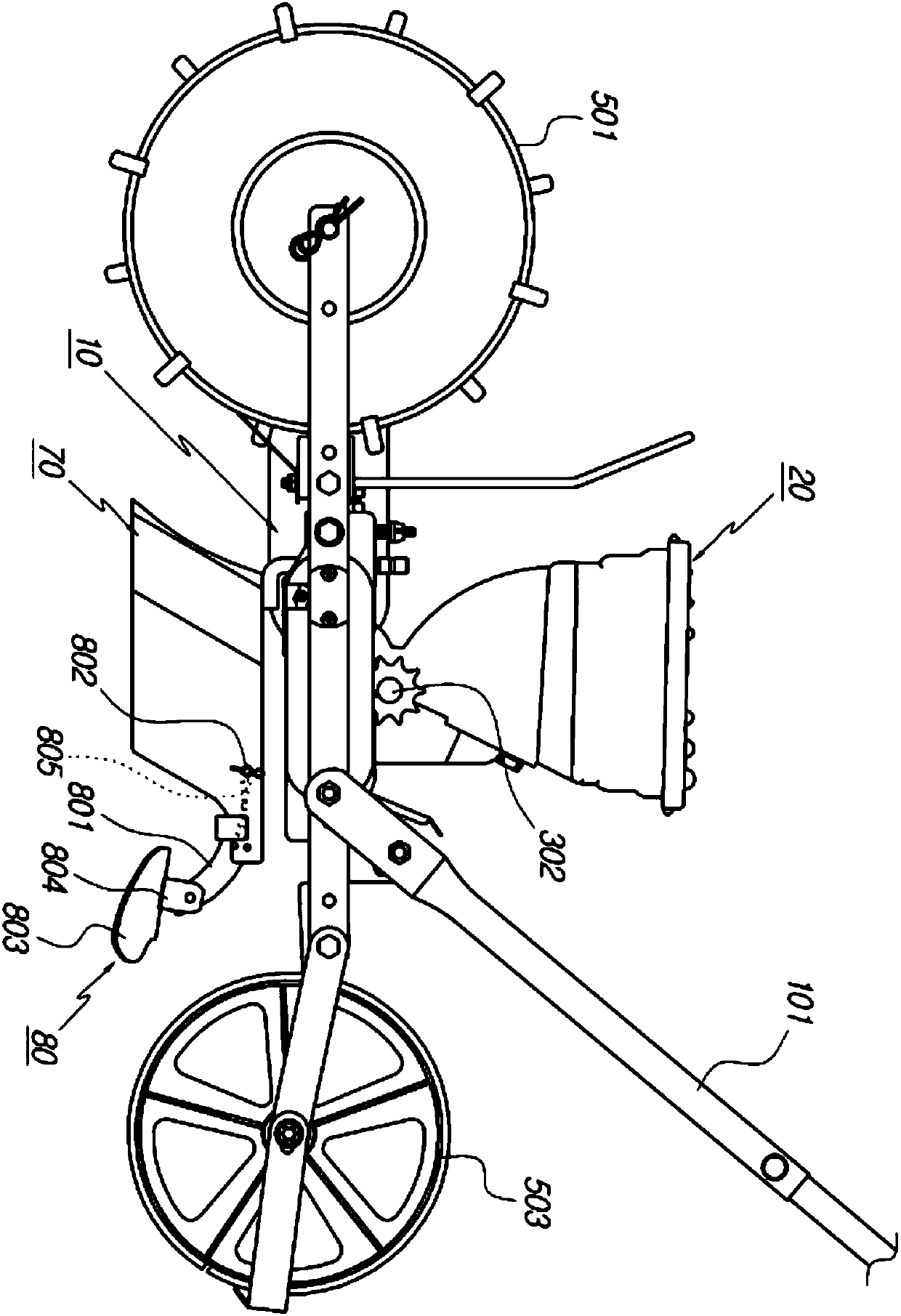

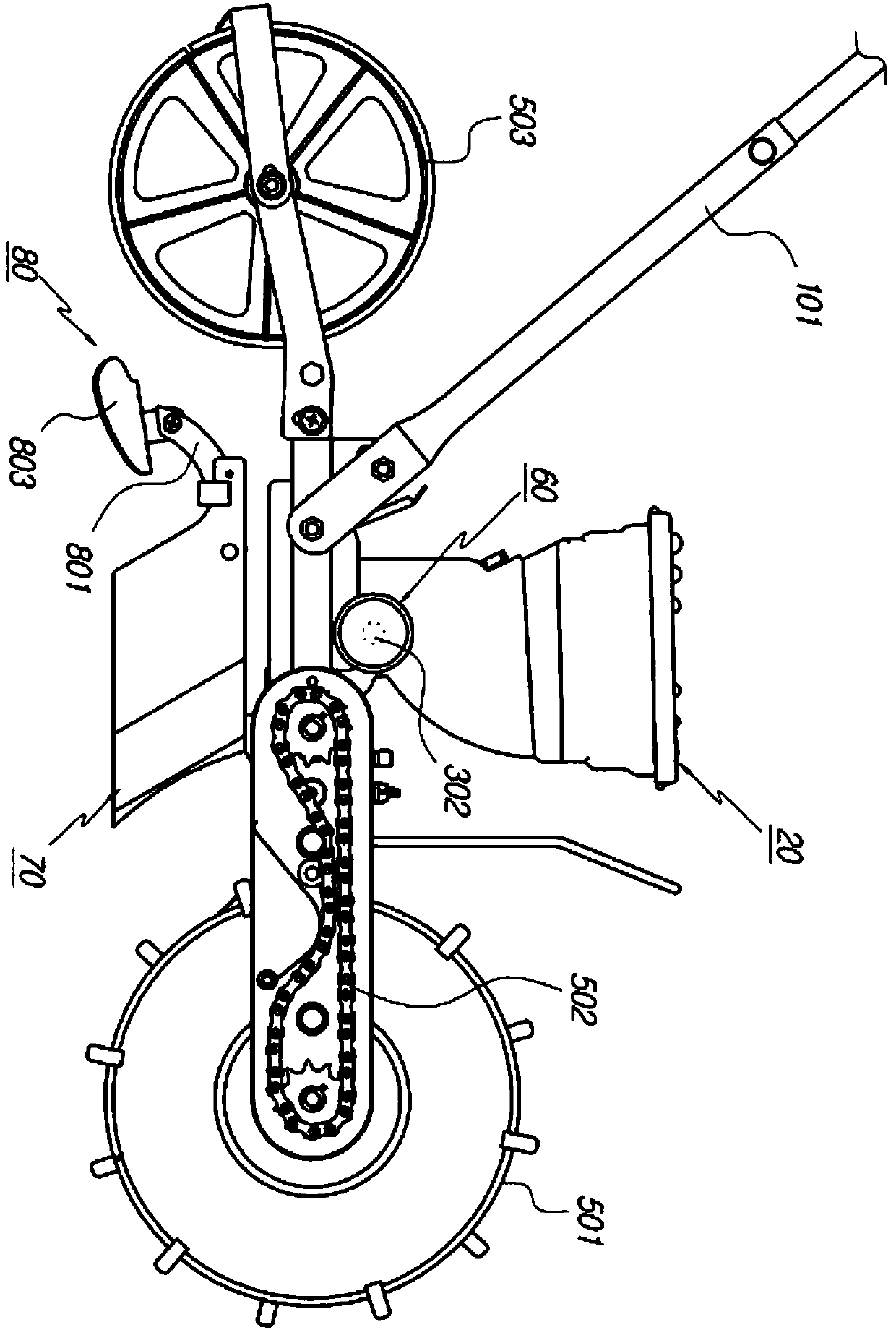

[0039] Hereinafter, the structure and function of a preferred embodiment of the seeder with electrostatic discharge function according to the present invention will be described in more detail with reference to the accompanying drawings. However, the following description is not intended to limit the technical idea of the present invention to description. It should be understood that the specific embodiments of the present specification include various modifications, equivalents, and / or alternatives of the embodiments of the present invention.

[0040] The expressions such as "first" and "second" used in the present invention have nothing to do with order and / or importance, and are only used to distinguish them from other constituent elements, and do not limit the constituent elements.

[0041] In addition, the terms used in the present invention are only used to describe a specific embodiment, and may not be intended to limit the scope of other embodiments, and the singular ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com