Automatic film-breaking type electric control seeding machine and method for peanuts

A technology of planter and film breaking, applied in the directions of planter parts, fertilizer and planting equipment, botanical equipment and methods, etc., can solve the problems of complex transmission structure, inconvenient operation, damage to peanut fields, etc. The effect of saving labor and preventing leakage of fertilizer and seeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

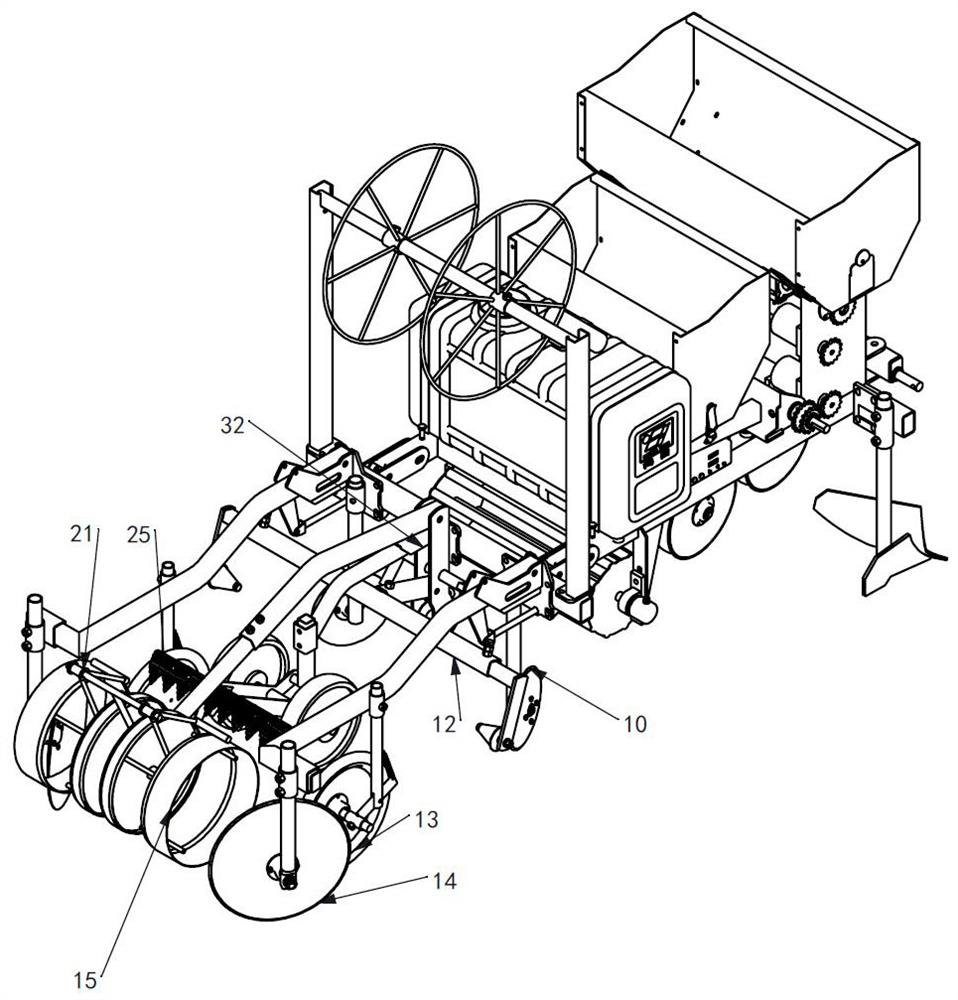

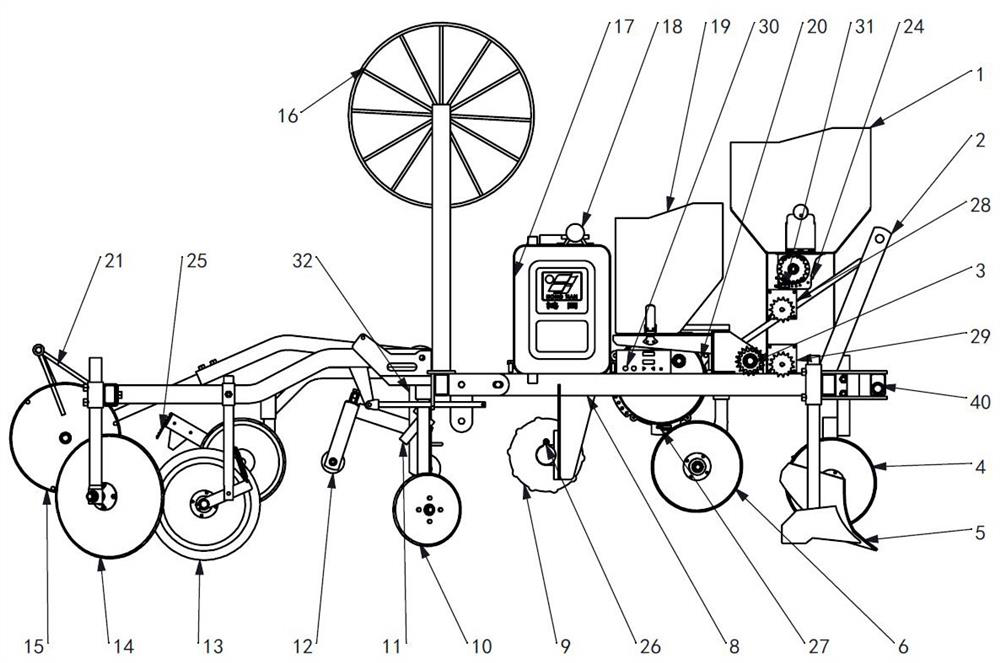

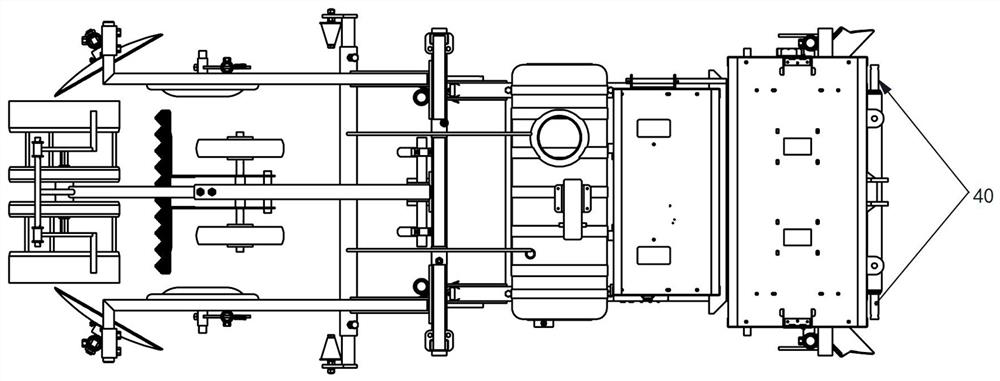

[0033] An electric control seeder with automatic cutting film for peanuts, comprising a frame 8, a ridger 5, a disc type fertilizer plow 4, a fertilizer box 1, a disc type plow 4, a seed box 19, a soil embossing roller 9, Medicine box 17, electric medicine pump 18, spray nozzle 11, drip irrigation tape laying rack 16, edge trimmer 10, mulching film laying rack 12, film pressing roller 13, soil submerging film device 14, film covering soil device 15, Soil cleaner 21 and film cutter 25, fertilizer box 1 is arranged on the frame 8, two disc type fertilizer plows 4 symmetrically arranged are arranged at the bottom of frame 8, and the fertilization pipe of fertilizer box 1 is positioned at two disc type. Between the fertilizer plows, the frame behind the fertilizer box 1 is provided with a seed box 19, and the bottom of the frame 8 is provided with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com