Automatic film mulching seeder

A seeder, automatic technology, applied in the directions of seeder parts, fertilizers and seeding equipment, plant protection covers, etc., can solve the problems of low efficiency of film-laying and seeding operations and increased manpower input.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

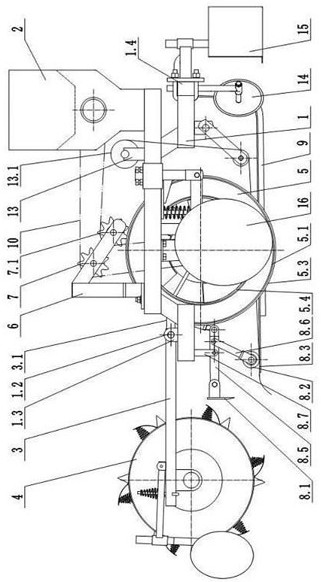

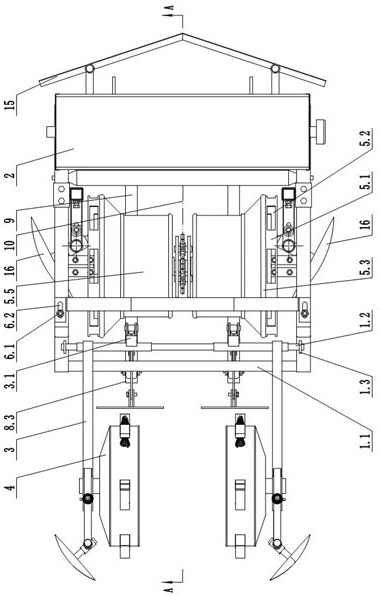

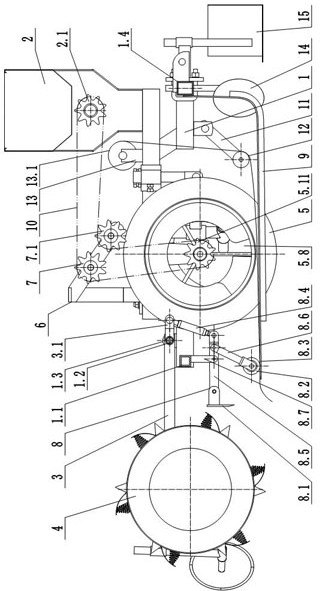

[0021] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

[0022] figure 1 -2: 1-Rack, 1.1-rack rear beam, 1.2-roller tutoring, 1.3-roller traction shaft hinge, 1.4 rack front end beam, 2-fat box, 2.1-fertilizer sprocket, 3 - Sowing drum rack, 3.1-link hinge, 4-seed roller, 5-pressure soil, 5.1-walking rim, 5.2-leak hole, 5.3-pressure film ring, 5.4-ground circle , 5.5- Soil roller, 5.6- fixed end cover, 5.7-end cover, 5.8-row water hole, 5.9-long film, 5.10-short film, 5.11-pressure traveling film cover roller sprocket, 6-play fertilizer chain Tensioning frame, 6.1-bolt, 6.2-bolt adjustment long hole, 7,7.1-tension sprocket, 8-automatic assembly membrane mechanism, 8.1-off film knife, 8.2-flap roller, 8.3-mezzanine Board, 8.4-link, 8.5-Franc-Film Rod, 8.6-flap roller, 8.7-off-membrane rod support, 9-anti-drift track, 10-chain, 11-exubebed roller, 12-exhibition Membrane roller, 13-ground film bracket, 13.1-floral film, 14-open groove, 15-flat floor, 16-earth.

[0023] Refer Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com