Fertilizer applying device for water chestnut planting

A fertilization device and the technology of water chestnuts, which are applied in the field of fertilization devices for planting water chestnuts, can solve the problems of fertilizer waste, fertilizer nutrient loss, and a large amount of labor, and achieve the effects of improving absorption effect, improving practicability, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

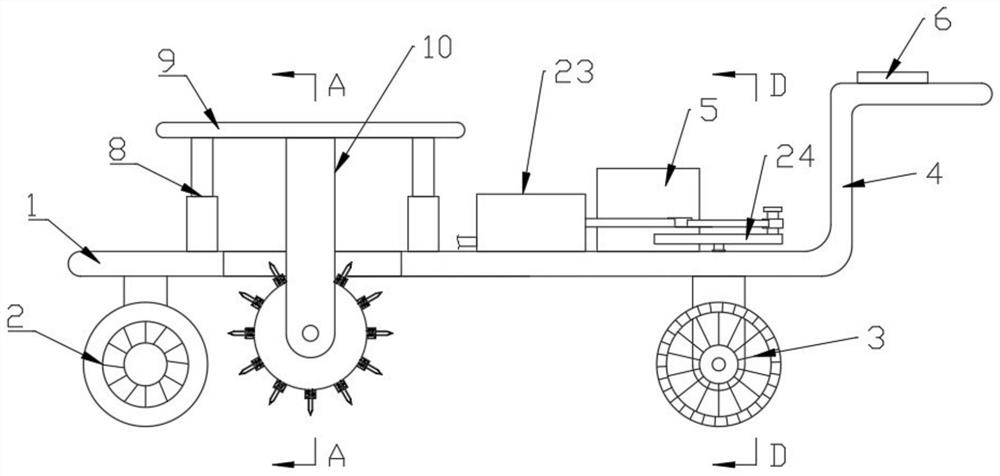

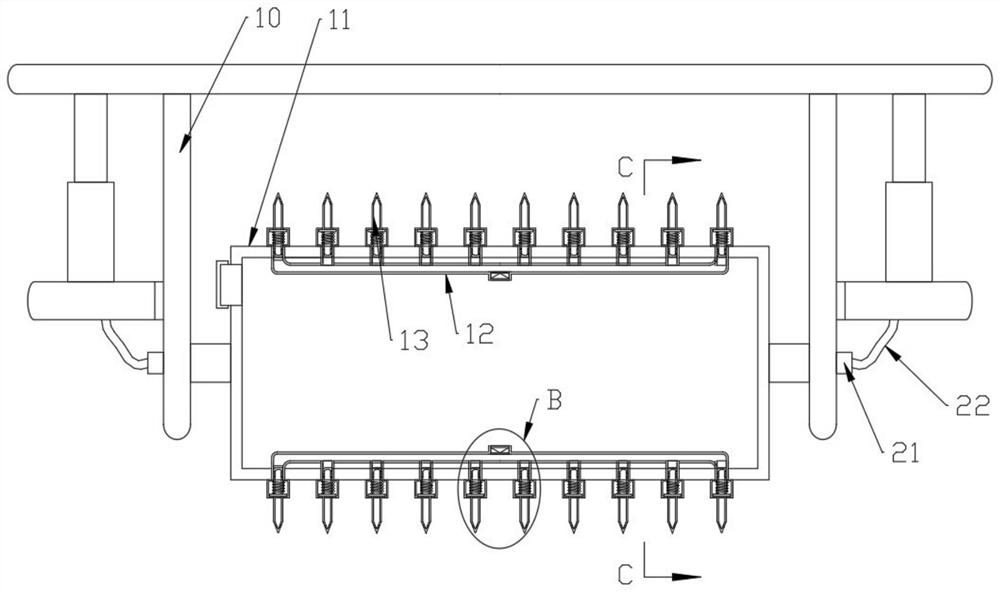

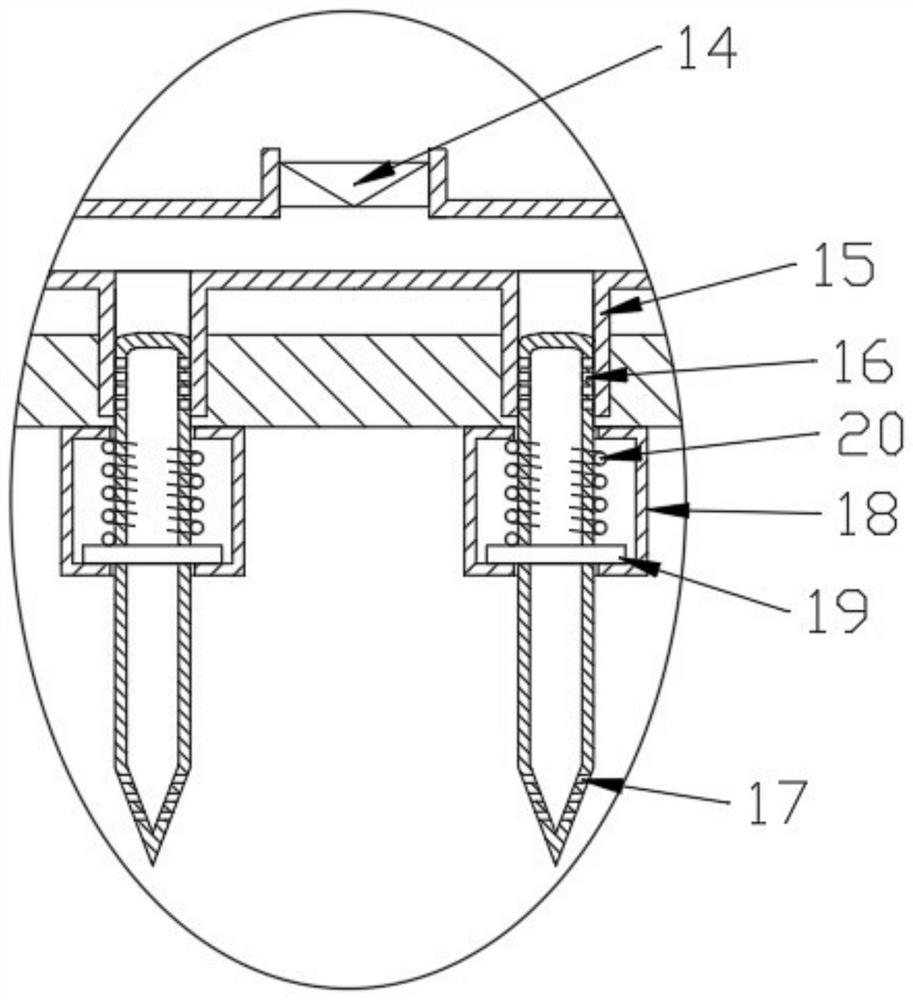

[0028] see Figure 1-8, a fertilization device for water chestnut planting, comprising a moving base 1 and two direction wheels 2 and two driving wheels 3 arranged under the moving base 1, a push rod 4 and a storage battery 5 are arranged on one side of the top surface of the moving base 1 , and the moving base 1 is located above the push rod 4 and is provided with a controller 6 electrically connected to the battery 5, the moving base 1 is provided with a through hole 7, and the top surface of the moving base 1 is located symmetrically on both sides of the through hole 7. There is an electric telescopic rod 8, the top of the electric telescopic rod 8 is fixedly provided with a support plate 9, and the bottom surface of the support plate 9 is symmetrically fixed with a mounting plate 10, and the mounting plate 10 is provided with a fertilization mechanism, and the fertilization The mechanism includes a tank body 11 rotatably connected between two mounting plates 10 and a plura...

Embodiment 2

[0033] This embodiment describes the drive assembly in detail on the basis of Embodiment 1, specifically:

[0034] The drive assembly includes a shaft sleeve 30, a first rotating shaft 31, a fixed box 32 and a drive shaft 33. There are two shaft sleeves 30, and the two shaft sleeves 30 are symmetrically fixed on the bottom surface of the moving seat 1, and The adjacent surfaces of the two shaft sleeves 30 are symmetrically fixed with a fixed box 32, and the adjacent surfaces of the two fixed boxes 32 are symmetrically provided with a chute 34, and the two ends of the first rotating shaft 31 pass through the chute 34 and is rotatably connected with the fixed box 32, and the middle part of the rod body of the first rotating shaft 31 is fixedly provided with a worm 35, one end of the drive shaft 33 is fixedly connected with the turntable 24, and the other end of the drive shaft 33 runs through the moving base 1 and is rotatably connected with it , and the end of the drive shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com