Drum type rice precise hill seeder

A hole-seeding machine and drum-type technology, applied in the field of roller-type rice precision hole-seeding machines, can solve the problems of rough surface of rice seeds, difficult to meet the requirements, and low seeding precision, and achieve simple and reliable mechanical structure, low manufacturing cost, and structural well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] See attached picture.

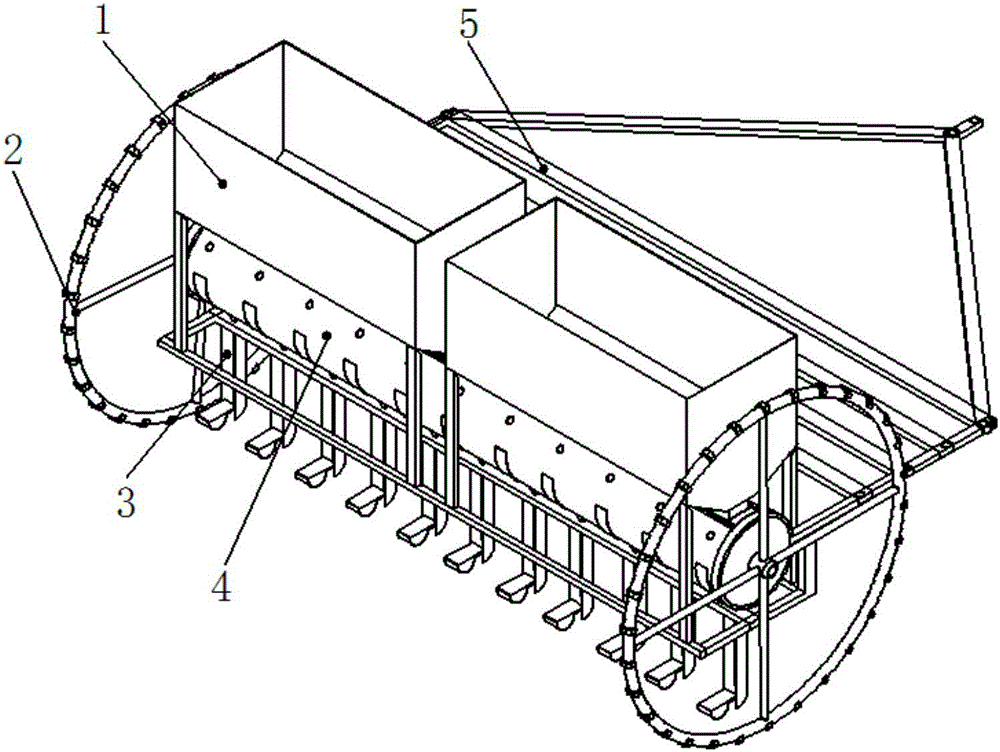

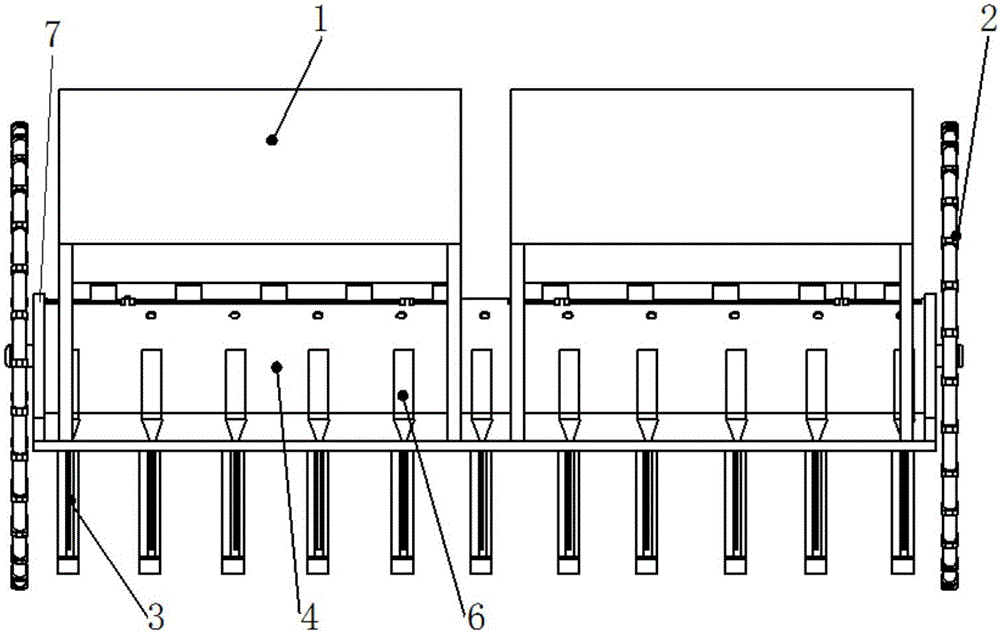

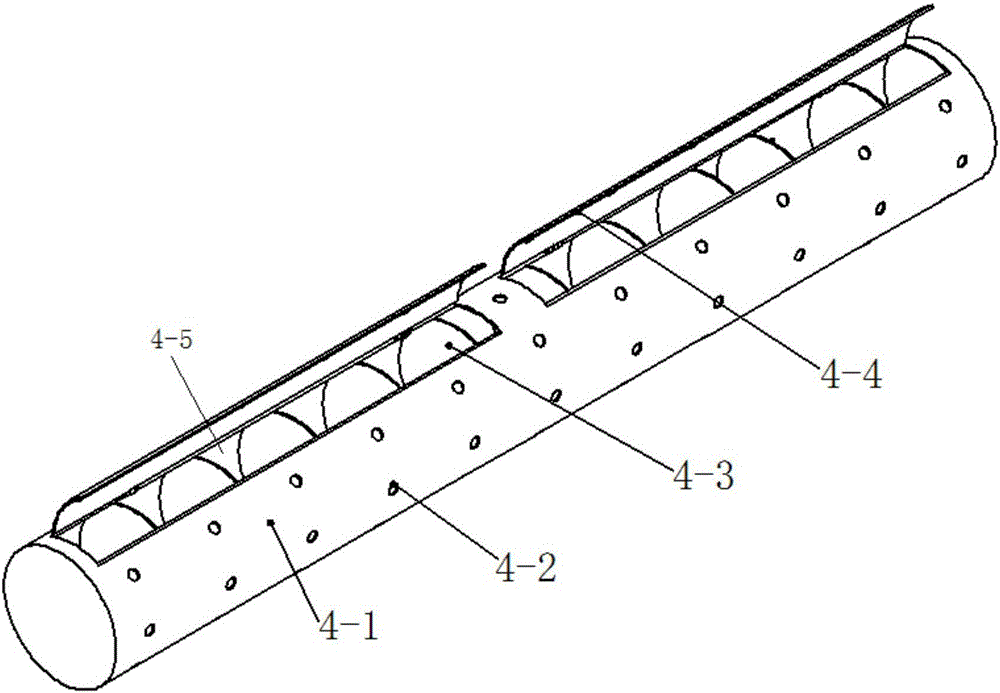

[0031] A drum-type precision hole seeder for rice, comprising a seed box 1, a walking wheel 2, a ditching device 3, a roller device 4, a traction frame 5, a seeding device 6, and a ratchet 7; the traction frame 5 is equipped with a roller Device 4, the drum device 4 includes a cylinder 4-1, the upper end surface of the cylinder is provided with an inoculation port 4-5, the inoculation port 4-5 is equipped with a cover plate 4-4 that is fastened with it, and the cylinder 4- The outer circumferential surface of 1 is evenly distributed with seed outlets 4-2 distributed at equal intervals, and the cylinders between adjacent seed outlets 4-2 are respectively provided with circular baffles perpendicular to the axial direction of the cylinder 4-1. Plate 4-3, the two ends of the drum device 4 are equipped with traveling wheels 2 that rotate synchronously with it, the top of the drum device 4 is equipped with a seed box 1, and the bottom of the drum devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com