Automatic control system for height of cutting table of combine-harvester

An automatic control system and combine harvester technology, applied to harvesters, cutters, mechanical equipment, etc., can solve problems such as machine blockage, machine failure, poor real-time performance and accuracy, and achieve precise sowing, avoid waste, The effect of improving harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

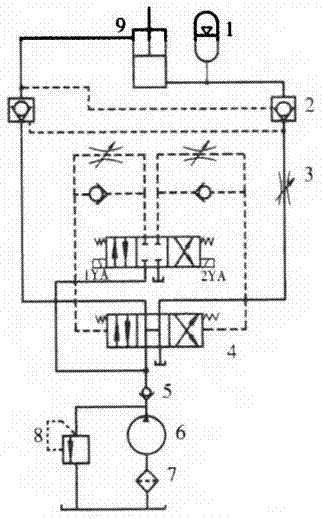

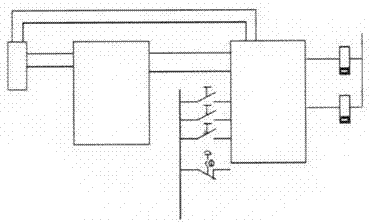

[0017] Such as figure 1 , The hydraulic system consists of accumulators, hydraulic control check valves, speed control valves, electro-hydraulic reversing valves, check valves, hydraulic pumps, filters, overflow valves, hydraulic cylinders and other basic components. Main function: Accept the signal sent by the controller to control the hydraulic circuit to ensure that the header has the positions of rising, falling and maintaining the original position.

[0018] When the controller sends a signal to lift the header, at this time, 2YA in the electro-hydraulic reversing valve 4 is energized, the auxiliary control valve is in the right position, the hydraulic pump outputs hydraulic pressure, and the main control valve is in the right position, and the liquid enters the hydraulic cylinder The lower chamber, the hydraulic cylinder rises. When the hydraulic cylinder rises ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com