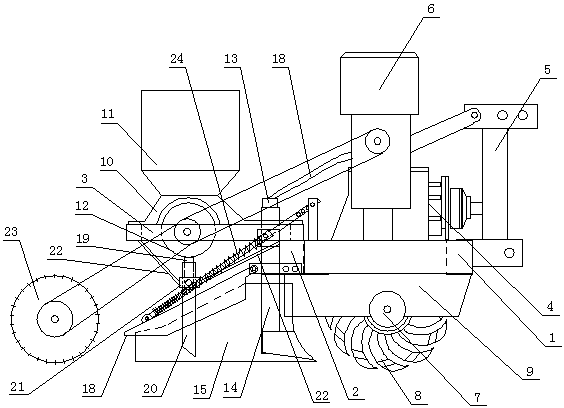

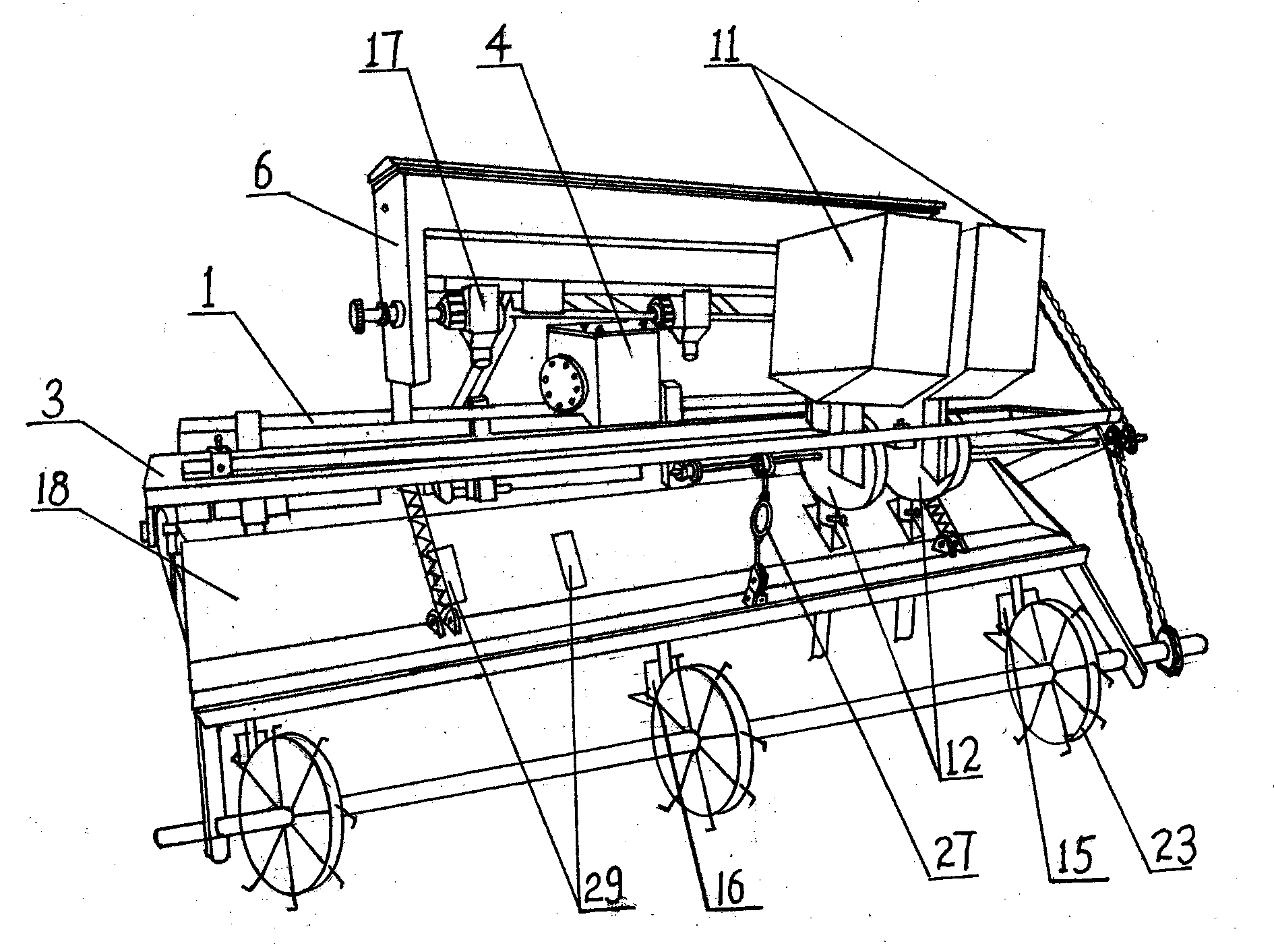

Rotary tillage, ridging, sowing and fertilizing all-in-one machine

An all-in-one machine and rotary tiller technology, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve the problems of burning seeds, excessive equipment, mechanical dragging, etc., to reduce trouble and loss, eliminate trouble and loss, Ease of disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

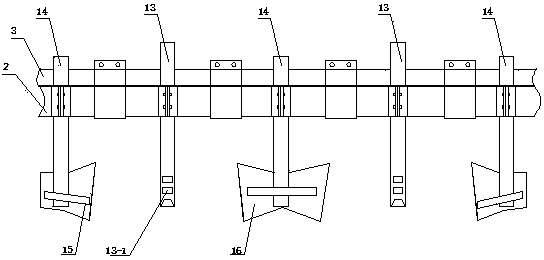

[0036] The difference between this embodiment and Embodiment 1 is that: the casing 21 and the support rod 22 are located above the cover plate 18, the casing 21 is connected with the sliding sleeve provided on the square bracket 3 through the support rod 22, and the sliding The kit is secured to the square bracket by pins, such as Figure 7 As shown, two adjacent bushings 21 are connected to the same sliding sleeve on the front side of the square bracket 3 through support rods 22, and the two bushings 21 are connected by transverse connecting rods, thereby effectively forming a stable triangular structure, Simultaneously, by being set on the transverse link, the support bar 22 that is perpendicular to the transverse link and connected with the sliding sleeve set on the rear side of the square support 3, when sowing, the support bar 22 that is connected with the front side of the square support 3 is opposite to the sowing tube. Form a pulling force, and the supporting rod 22 co...

Embodiment 3

[0038] The difference between this embodiment and the first embodiment is that the casing 21 is fixed on the cover plate 18, and has a matching arc with the seeding pipe, such as Figure 8 As shown, its arc is centered on the center line of the rotating shaft of the cover plate 18, and at the same time, the inner pipe 19 arranged on the outlet of the seeder is also an arc-shaped structure with the same radian, thereby effectively adapting to the rotation of the cover plate 18 and the outer surface of the cover plate 18. Tube 20 height adjustment. By fixing the sleeve pipe 21 on the cover plate, on the one hand, when adjusting the height of the cover plate to realize the adjustment of the ridge height, the position of the lower end of the sowing pipe and the cover plate 18 can be kept unchanged, so that the sowing depth can be kept stable, avoiding Because the adjustment of the height of the ridge causes the change of the sowing depth, on the other hand, it can effectively impr...

Embodiment 4

[0040] Such as Figure 9 As shown: the difference between this embodiment and the first embodiment is that the rotating shaft of the ground wheel 23 is hinged to the rear beam 2 through the connecting rod 27, and a spring pressing rod is arranged between the connecting rod 27 and the square bracket 3 28. One end of the spring pressing rod 28 is hinged with the connecting rod 27, and the other end is slidingly connected with the sliding sleeve provided on the square bracket 3, and one end of the spring inserted on the spring pressing rod 28 is against the sliding sleeve. sleeve, the other end is against the connecting rod 27 or against the limit boss arranged at the lower end of the spring pressure rod 28, and the top of the spring pressure rod 28 is inserted with a pin to prevent the spring pressure rod 28 from slipping off from the sliding sleeve. The ground wheel 23 is compressed in the groove by the spring pressure rod 28, on the one hand the overall structure of the ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com