Telescopic type tool face stabilizer

A tool face, telescopic technology, used in directional drilling, drilling equipment, earth-moving drilling, etc., can solve the problems of torsional deformation of the drill string, difficulty in stabilizing the tool face, and easy deviation, so as to prevent deviation, and the operation is simple and reliable. , The effect of simple and reliable mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

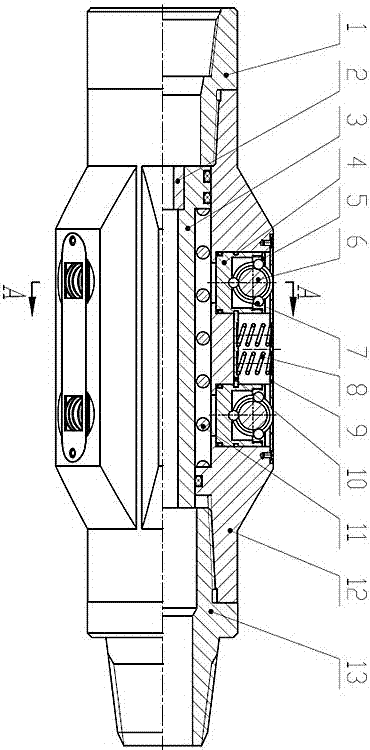

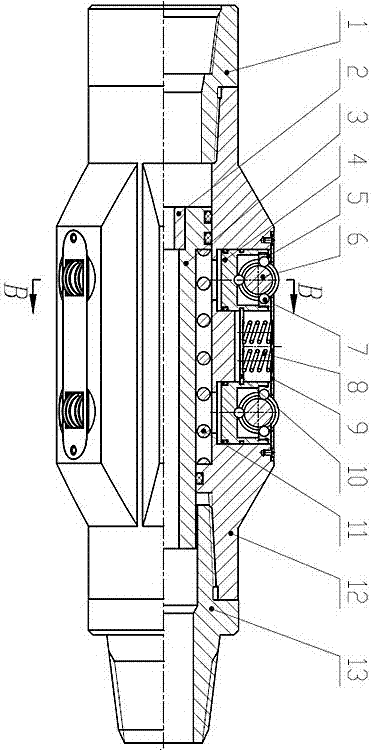

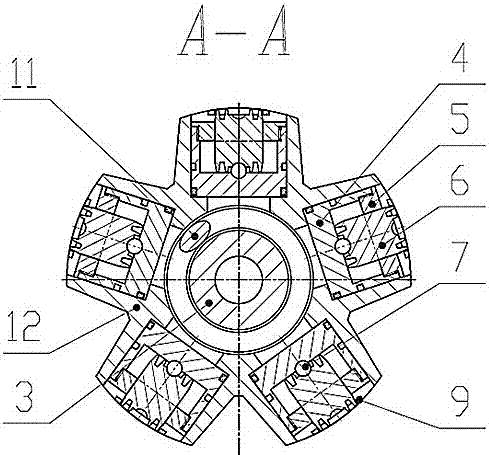

[0015] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a telescopic tool face stabilizer of the present invention is composed of an upper joint 1, a throttle nozzle 2, a mandrel 3, a roller seat 4, a roller cover 5, a roller 6, a steel ball 7, a return spring 8, a pressing plate 9, The connection plate 10, the mandrel spring 11, the stable housing 12 and the lower joint 13 are composed; its structural features are: a ring of sealing grooves is arranged on the lower part of the outer circle of the roller seat 4, a ring of grooves is arranged on the middle part of the outer circle, and the inner cavity of the roller seat 4 It is set as a blind hole, and the center of the lower end of the blind hole is provided with a hemispherical groove; the center of the roller cover 5 is provided with a rectangular through hole, and the two ends of the rectangular through hole are arranged as arc surfaces, and hemispherical grooves are respectively arranged on the two arc s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com