Vertical type cable former with back-twist control function

A vertical cable forming machine and untwisting technology, which is applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as undiscovered technical solutions, achieve simple and reliable mechanical structure, stable and convenient electrical control, and ensure production quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

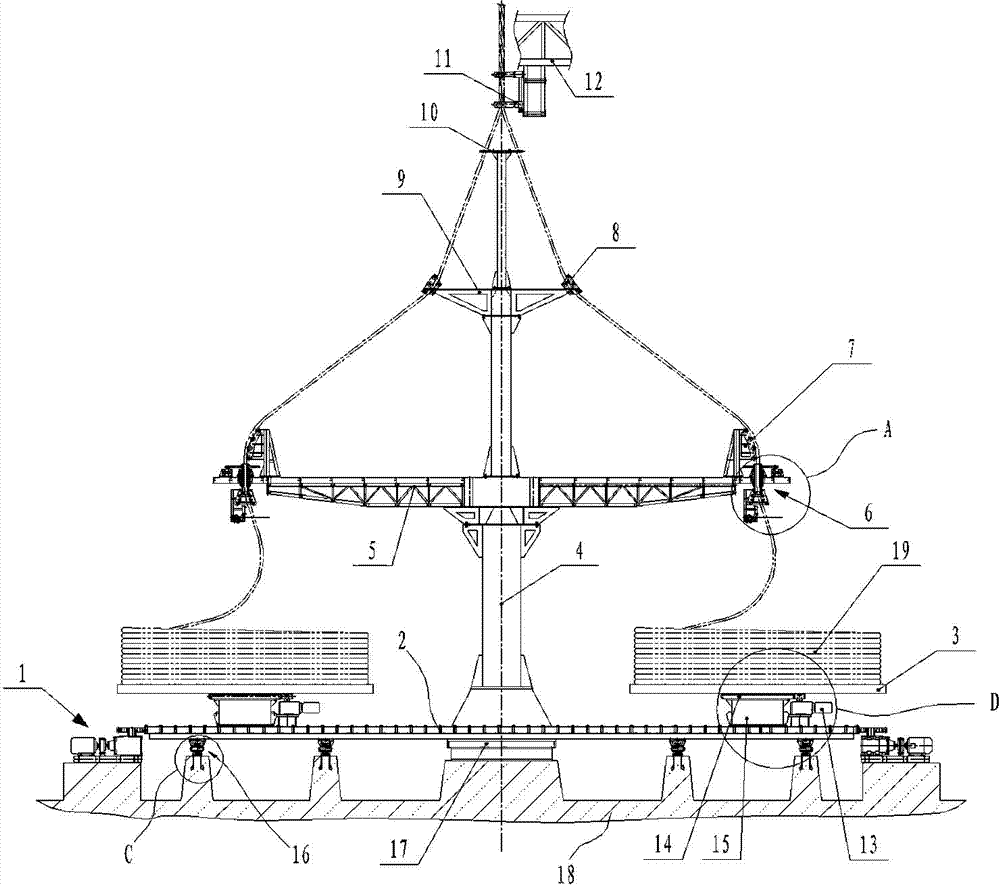

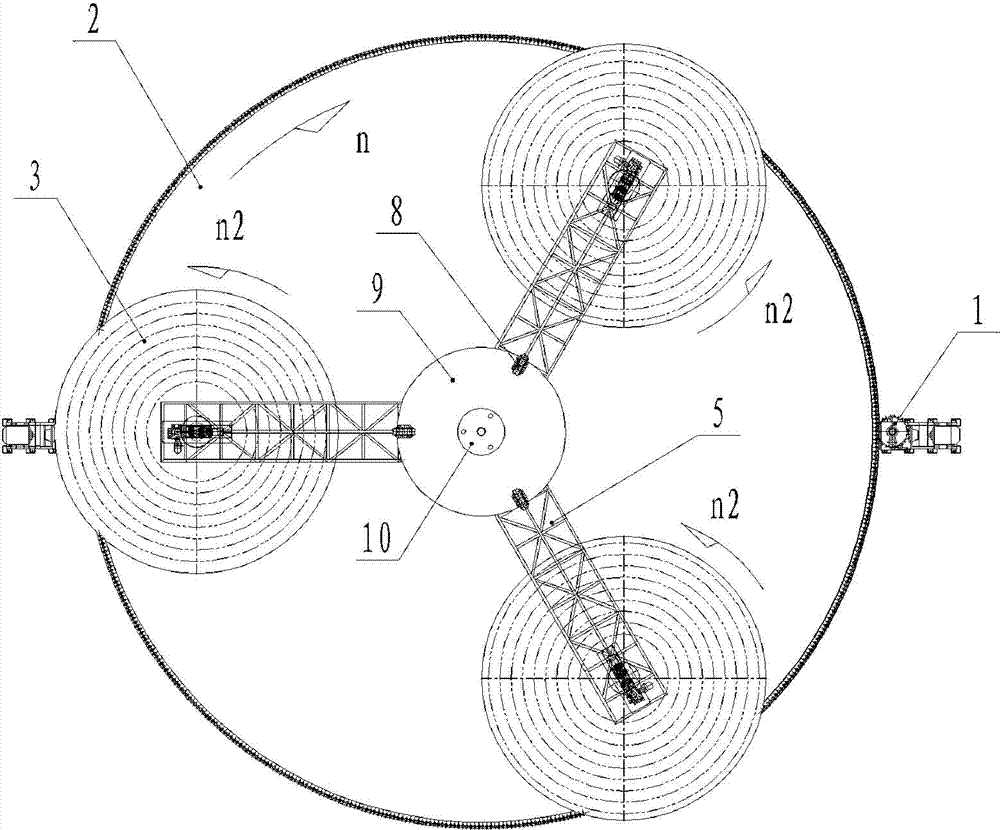

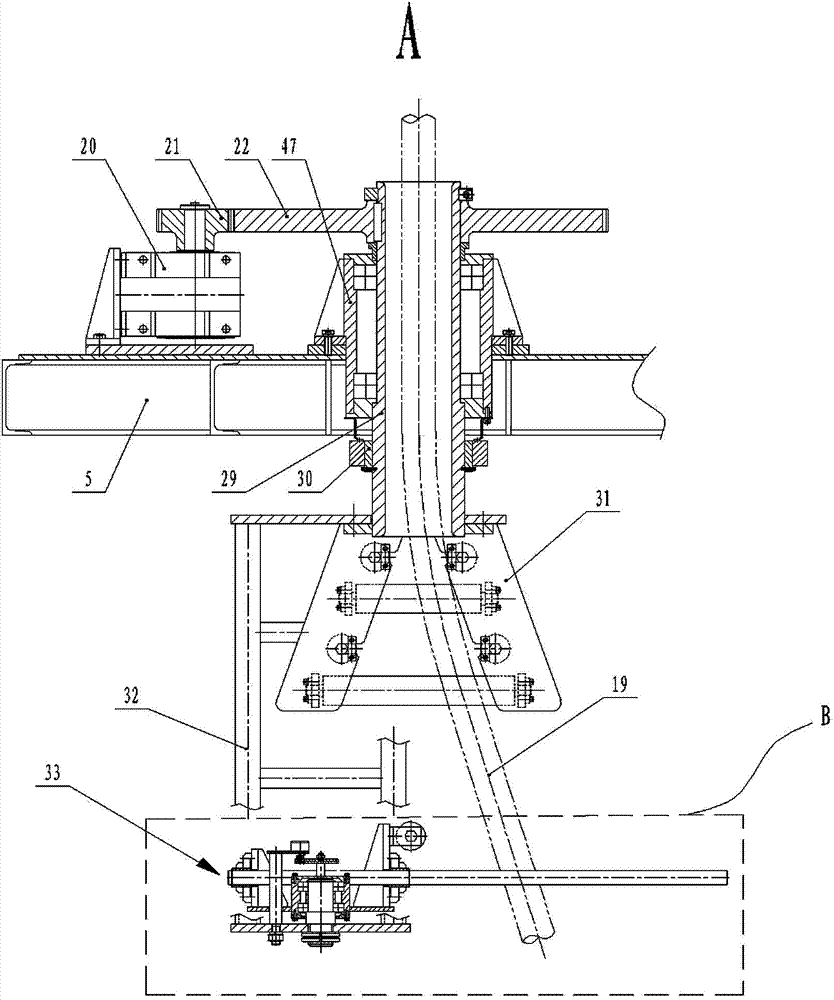

[0025] Such as figure 1 , figure 2 and image 3 As shown, a kind of vertical cabling machine with back twist control that the present invention provides, comprises base 18, is provided with turntable support 17 on base 18, is also provided with a group of supporting roller device 16 on base 18, described The idler device 16 includes an idler base 16a, the idler base 16a is fixed on the base 18 by bolts 16b, the idler base 16a is connected with the idler roller 16c through a bearing, and the idler 16c is matched with the support base 2a, the support base 2a Connect the twisted turntable 2 by screws, connect the twisted turntable 2 on the turntable bracket 17 and the support wheel device 16, connect the column 4 on the turntable support frame 17, and connect the distribution box 10 on the upper end of the column 4 , a platform support 12 is correspondingly arranged above the line distribution disc 10, a double row mold base 11 is provided on the platform support 12, and a dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com