Fruit peeler

A peeling machine and fruit technology, applied in the peeling of vegetables or fruits, food science, application, etc., can solve the unfavorable problems of fully automatic assembly line processing, etc., and achieve the effect of simple and reliable mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

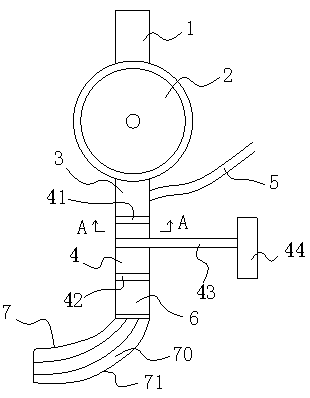

[0011] Below with reference to the accompanying drawings, through the description of the implementation examples, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between each part, the role and working principle of each part, etc., will be further described. detailed description of the .

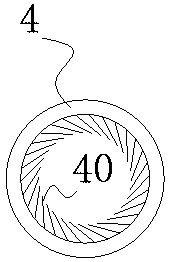

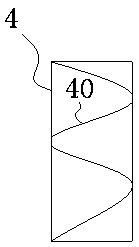

[0012] Such as figure 1 , 2 , 3, the fruit peeling machine of the present invention, comprises feed channel 1, peeling cylinder 2 and discharge channel 3, discharge channel 3 is connected with cleaning pipeline 4 upper ends by ball bearing 41, and discharge channel 3 inner wall is connected and is provided with Towards the water spray pipe 5 of the cleaning pipeline 4, the lower end of the cleaning pipeline 4 is connected to the feeding passage 6 through a ball bearing 42, the bottom of the feeding passage 6 communicates with the separation passage 7, and the outer wall of the cleaning pipeline 4 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com