ERD (Efficient Reburning Denitration)+coal saturated steam catalytic combustion denitration device and technique

A catalytic combustion and catalytic burner technology, applied in gasification process, chemical industry, petroleum industry, etc., can solve problems such as after-combustion, and achieve the effects of significant heat consumption, low operating cost, and improved burnout rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

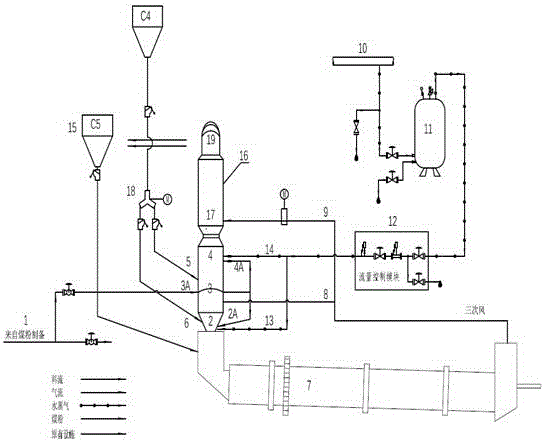

[0112] Such as figure 1 As shown, the present invention provides a kind of ERD+coal-fired saturated steam catalytic combustion denitrification device, comprising:

[0113] A calciner 16, the bottom of the calciner 16 is provided with a secondary air inlet, which is connected with the cement rotary kiln 7; The reduction zone 2 and the reburning zone 4 are respectively equipped with a saturated steam catalytic burner 13 in the reduction zone and a saturated steam catalytic burner 14 in the reburning zone; a C4 (fourth stage preheating separator) feeding pipe is installed in the main combustion zone 3 to enter the decomposition furnace The first raw material inlet 5, the C4 (fourth stage preheating separator) feeding pipe is installed at the position of the reduction zone 2 to enter the second raw material inlet 6 of the calciner; the main combustion zone 3 and the burnout zone 17 are respectively connected with the tertiary air and The burn-off air connection is an oxygen-enri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com