Method for treating sulfur-containing circulating cooling water

A technology of circulating cooling water and water treatment agent, applied in special treatment targets, water treatment parameter control, chemical instruments and methods, etc., can solve problems such as leakage, and achieve the effects of reducing energy consumption, simple operation, and saving pharmaceutical costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

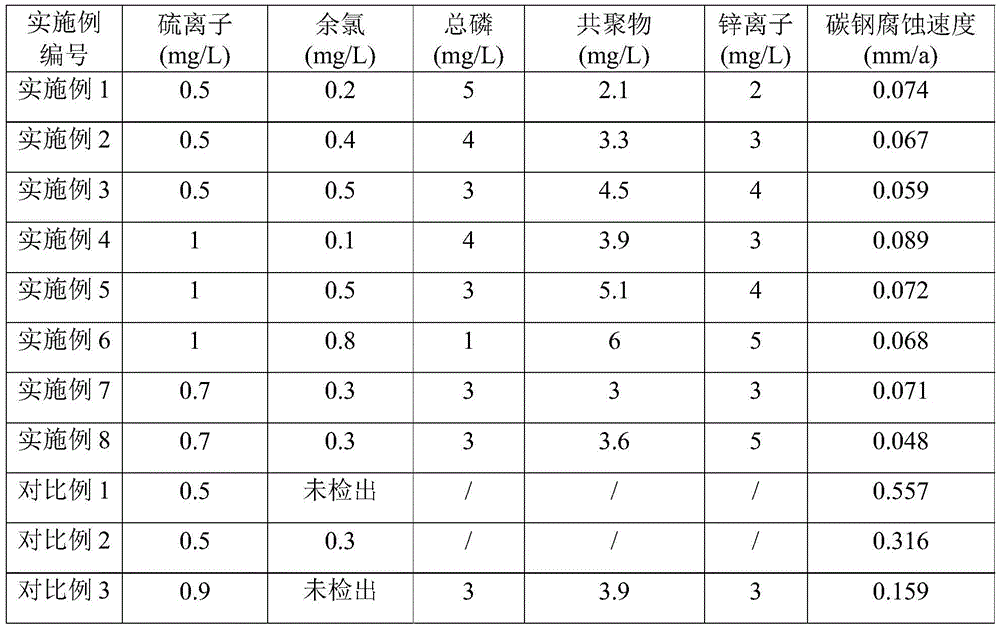

Examples

Embodiment 1

[0033] This example is used to illustrate the corrosion inhibition effect of using the method of the present invention to treat circulating cooling water containing sulfur.

[0034] The test water is the circulating water of a refinery. The water quality is: calcium ion 1350mg / L, total hardness 1980mg / L, total alkalinity 120mg / L, Cl - 570mg / L, S 2- 0.5mg / L, residual chlorine was not detected.

[0035] Dosing the corrosion test on the rotating coupons after adding chemicals to the test water in the following way:

[0036] Without changing the original chemical YSW105 (purchased from Beijing Yanhua Jilian Company) in the refinery, sodium hypochlorite was added to make the residual chlorine reach 0.2 mg / L, and a composite corrosion inhibitor (containing maleic anhydride / styrene sulfonic acid copolymerized The aqueous solution of substance, HEDP, benzotriazole and zinc chloride, wherein the maleic anhydride / styrene sulfonic acid copolymer is JNH-406 purchased from Langfang Jinnu...

Embodiment 2

[0038] This example is used to illustrate the corrosion inhibition effect of using the method of the present invention to treat circulating cooling water containing sulfur.

[0039] The test water is the circulating water of a refinery. The water quality is: calcium ion 1350mg / L, total hardness 1980mg / L, total alkalinity 80mg / L, Cl - 570mg / L, S 2- 0.5mg / L, residual chlorine was not detected.

[0040] Dosing the corrosion test on the rotating coupons after adding chemicals to the test water in the following way:

[0041] Without changing the original chemical YSW105 (purchased from Beijing Yanhua Jilian Company) in the refinery, add sodium hypochlorite to make the remaining chlorine reach 0.4 mg / L, add sodium bicarbonate to make the total alkalinity reach 120 mg / L, add compound Corrosion inhibitor (the aqueous solution containing acrylic acid / styrene sulfonic acid copolymer, HPAA and zinc nitrate, wherein acrylic acid / styrene sulfonic acid copolymer is AA-SSA purchased from H...

Embodiment 3

[0043] This example is used to illustrate the corrosion inhibition effect of using the method of the present invention to treat circulating cooling water containing sulfur.

[0044] The test water is the circulating water of an oil refinery. The water quality is: calcium ion 850mg / L, total hardness 1250mg / L, total alkalinity 180mg / L, Cl - 360mg / L, S 2- 0.5mg / L, residual chlorine was not detected.

[0045] Dosing the corrosion test on the rotating coupons after adding chemicals to the test water in the following way:

[0046] Without changing the original agent YSW105 (purchased from Beijing Yanhua Jilian Company) in the refinery, sodium hypochlorite was added to make the remaining chlorine reach 0.5 mg / L, and a composite corrosion inhibitor (containing maleic anhydride / allyl sulfonic acid Copolymer, HEDP / ATMP mixed solution, aqueous solution of zinc sulfate, wherein the maleic anhydride / allylsulfonic acid copolymer is SY-414 purchased from Lianyungang Sanyi Water Treatment D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com