Inhibitor for controlling electric dipole corrosion

A galvanic corrosion and corrosion inhibitor technology, applied in the field of corrosion inhibitors, can solve problems such as unsatisfactory galvanic corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

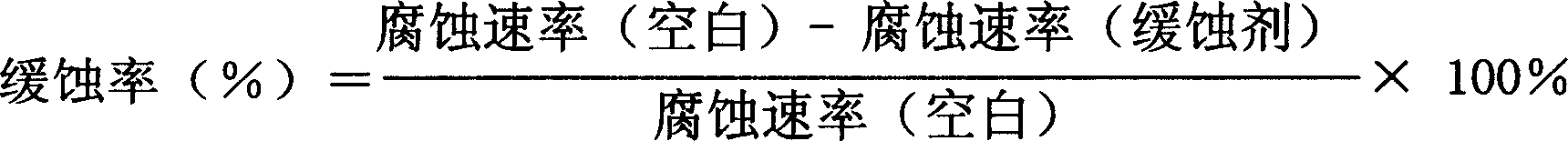

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the corrosion inhibitor is to mix and stir the fatty amine polyoxyethylene ether, propynyl alcohol, ethylenediamine, ethanol and water evenly.

[0019] The corrosion inhibitor provided by the present invention can be used in various corrosive media that cause galvanic corrosion, such as in the completion fluid, although the corrosion inhibitor provided by the present invention can be used to control galvanic corrosion, but preferably, the Based on the weight of the corrosive medium, the usage amount of the corrosion inhibitor is 0.5-5.0% by weight, preferably 1.0-4.0% by weight.

[0020] The present invention will be described in more detail through specific embodiments below.

Embodiment 1

[0022] This embodiment is used to prepare completion fluid.

[0023] The completion fluid can be obtained by mixing 265 grams of potassium chloride, 20 grams of dimethyl diallyl ammonium chloride, 3 grams of sulfamic acid, 2 grams of sodium sulfite and 1000 grams of seawater.

Embodiment 2

[0025] This embodiment is used to prepare the corrosion inhibitor provided by the present invention.

[0026] 70 grams of fatty amine polyoxyethylene ether (CH 3 -(CH 2 ) 7 -NH-(CH 2 -CH 2 -O) 9 -H), 30 grams of propynyl alcohol are mixed and stirred evenly to obtain the corrosion inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com