Treatment system and method for dehydration and desalination of crude oil

A crude oil dehydration and treatment system technology, which is applied in the field of crude oil dehydration and desalination treatment systems, can solve the problems of unqualified salt and water content indicators, high oil content and water content, increase the number of oil-water mixing and separation, improve dehydration and desalination, and prolong the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

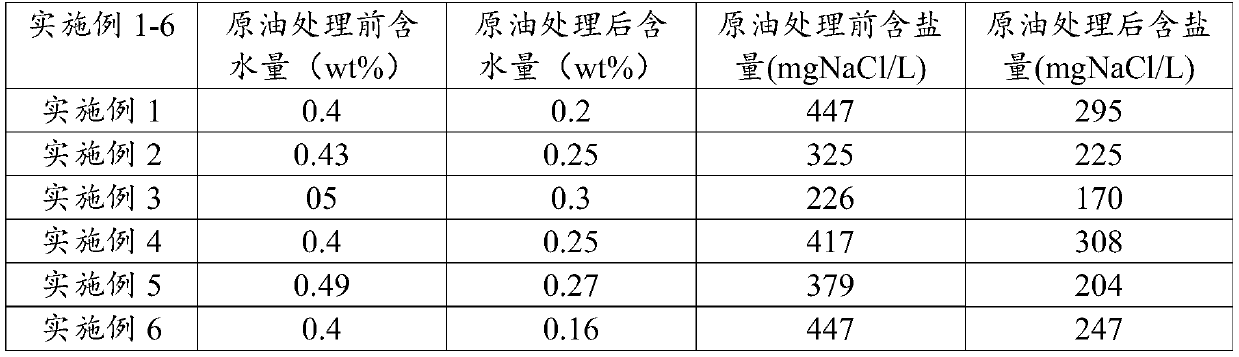

Embodiment 1

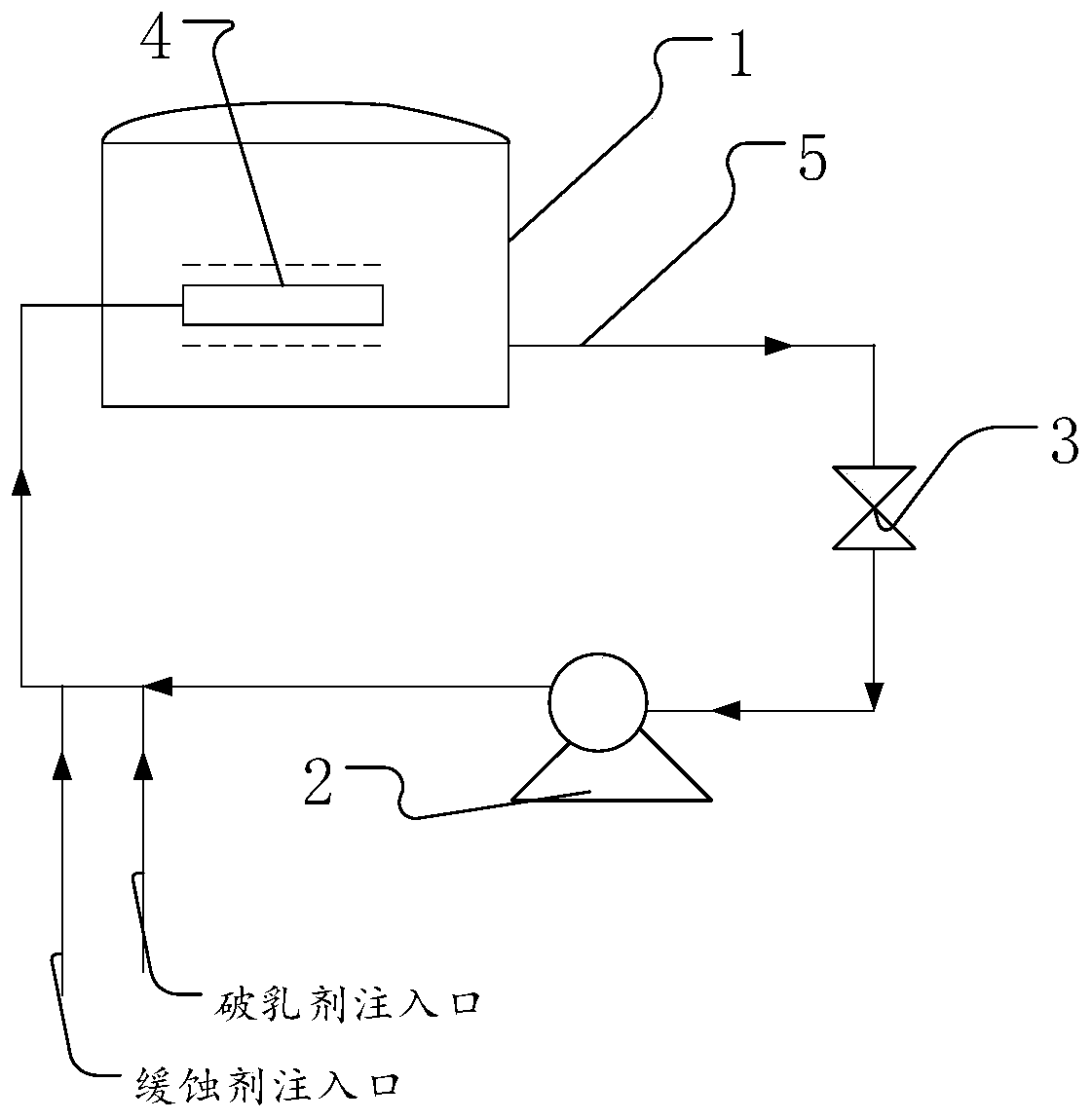

[0079] A treatment system for crude oil dehydration and desalination, such as figure 1 As shown, it includes a crude oil storage tank 1 and a return line 5; both ends of the return line 5 communicate with the bottom of the crude oil storage tank 1 to form a closed loop; the crude oil storage tank 1 is provided with an inlet distributor 4 The liquid inlet distributor 4 communicates with the drain port of the return line 5; the return line 5 is provided with a delivery pump 2 and a valve 3; the return line 5 is provided with a demulsifier injection port and a corrosion inhibitor injection port Entrance;

[0080] The method for dehydrating and desalting crude oil comprises the following steps:

[0081] Put the crude oil into the crude oil storage tank 1, firstly carry out the thermal sedimentation treatment, the temperature of the thermal sedimentation is 75°C, and the standing time is 7 hours. After the oil and water are separated, drain the water, and transport the drain water...

Embodiment 2

[0083] A treatment system for crude oil dehydration and desalination, same as Example 1;

[0084] The method for dehydrating and desalting crude oil comprises the following steps:

[0085] Put the crude oil into the crude oil storage tank 1, firstly carry out the thermal sedimentation treatment, the temperature of the thermal sedimentation is 65°C, and the standing time is 8 hours. After the oil and water are separated, the drain is carried out, and the drain is transported again through the return pipeline 5 by the delivery pump 2 To the bottom of the crude oil storage tank 1, the water is evenly distributed through the liquid inlet distributor 4, and the oil and water are mixed. At the same time, 7 μg / g of RUN-131 oil-soluble demulsifier and 12 μg / g of corrosion inhibitor benzotriazole are added, and the water is drained into the crude oil storage tank. The temperature of the tank is 60°C, and the residence time is 36h. After standing for stratification, the oil and water ar...

Embodiment 3

[0087] A treatment system for crude oil dehydration and desalination, same as Example 1;

[0088] The method for dehydrating and desalting crude oil comprises the following steps:

[0089] Put the crude oil into the crude oil storage tank 1, firstly carry out the thermal sedimentation treatment, the temperature of the thermal sedimentation is 65°C, and the standing time is 8 hours. After the oil and water are separated, the drain is carried out, and the drain is transported again through the return pipeline 5 by the delivery pump 2 To the bottom of the crude oil storage tank 1, distribute water evenly through the liquid inlet distributor 4, and mix oil and water. At the same time, add JH-1 water-soluble demulsifier 20μg / g, corrosion inhibitor benzotriazole 20μg / g, and drain into the crude oil storage The temperature of the tank is 60°C, and the residence time is 30h. After standing for stratification, the oil and water are separated, and the water content and salt content of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com