Corrosion inhibitor and preparation method thereof

A technology of corrosion inhibitor and Mannich base, used in chemical instruments and methods, earthwork drilling, wellbore/well components, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

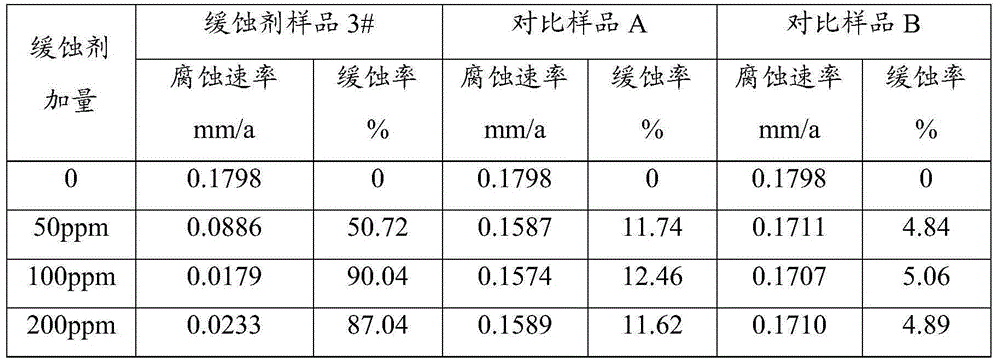

Examples

preparation example Construction

[0032] Specifically, the preparation method of the Mannich base includes the following steps:

[0033] (1) Add 1 part by weight of N-methylaniline to a three-necked flask and heat it to 80°C with an electric heating mantle. Use concentrated hydrochloric acid to adjust the pH to 2; in addition to adjusting the pH, the concentrated hydrochloric acid also acts as a catalyst ;

[0034] (2) Heat the flask to 95°C, add 1 part by weight of acetone to the flask, and heat to 150°C;

[0035] (3) Add 0.5 parts by weight of formaldehyde and 0.5 parts by weight of benzaldehyde to the flask, keep the temperature at 150°C, and reflux for 4 hours under stirring to obtain Mannich base;

[0036] Wherein, the above steps are all carried out under reflux of the condenser. Steps (1) and (2) adopt reflux of the condenser. On the one hand, the temperature in the flask can be kept constant, and on the other hand, the components in the flask can be prevented from volatilizing.

[0037] Preferably, the preparat...

Embodiment 1

[0049] Example 1 Preparation of Mannich base

[0050] Add 10g of N-methylaniline to a 500ml three-necked flask. The equipment range is a thermometer, stirring device and reflux device at 200°C. Use an electric heating mantle to heat to 80°C, reflux, and adjust the pH of the solution to 2 with concentrated hydrochloric acid; Continue heating the solution to 95°C, add 10g of acetone to the flask and heat it to 150°C; add 5g of formaldehyde and 5g of benzaldehyde to the flask, keep the temperature at 150°C, reflux for 4 hours under stirring, and obtain Mannich base sample 1 #.

Embodiment 2

[0051] Example 2 Preparation of Mannich base

[0052] Add 10g of N-methylaniline to a 500ml three-necked flask with a thermometer, stirring device and reflux device with a range of 200°C. Use an electric heating mantle to heat to 80°C, reflux, and adjust the pH of the solution to 2 with concentrated hydrochloric acid; The solution continues to be heated to 95°C, add 10g of acetone to the flask and heat to 150°C; add 5g of formaldehyde and 5g of benzaldehyde to the flask, keep the temperature at 150°C, reflux for 4 hours under stirring; cool the refluxed three-necked flask to At room temperature, pour all the contents into a 500ml beaker; put the stirring magnet into the beaker, heat it to 180℃ while stirring, keep the beaker at 180℃ for 3min, pour the contents of the beaker into a 500ml three-necked flask , Install the reflux device, reflux at a constant temperature of 180°C for 1 hour to obtain Mannich base sample 2#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com