Dismantling-free stiffened composite template and manufacturing and using method thereof

A composite formwork and disassembly-free technology, which is applied in the field preparation of formwork/formwork components, building components, construction, etc., can solve the problems of large proportion of pigment usage, poor bonding compatibility, and product performance impact, and achieve adhesion High knot strength, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

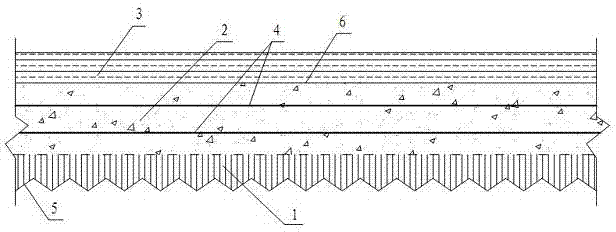

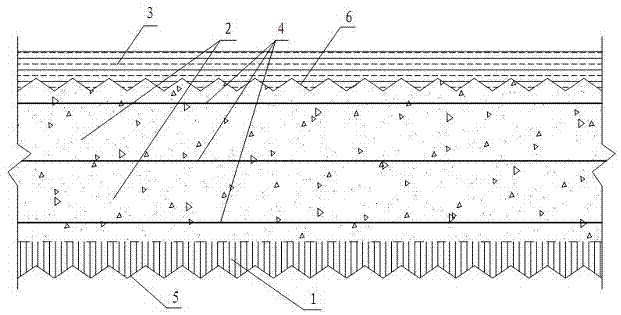

[0033] A disassembly-free stiffened composite formwork includes an inner bonding layer 1 and an outer stiffening layer 2, the bonding layer 1 is poured from cement paste or concrete material, the outer surface of the bonding layer 1 and the inner surface of the stiffening layer 2 Connected by continuous pouring, the stiffening layer 2 is poured from concrete material and has two layers of high-strength stainless steel wire mesh skeleton 4 inside; the inner side 5 of the bonding layer is a rough surface; the outer side 6 of the stiffening layer is also a rough surface; The outer side 6 of the stiffening layer has a protective layer 3 .

[0034] Wherein, the above-mentioned high-strength stainless steel wire mesh skeleton 4 can be replaced by glass fiber mesh, carbon fiber mesh or polymer material mesh skeleton, also can be replaced by polyester mesh, polypropylene mesh or polyethylene mesh skeleton; protective layer 3 is a decorative protective layer , poured by cement paste mi...

Embodiment 2

[0036] A method for preparing a reinforced composite formwork without disassembly, the steps comprising:

[0037] (1) Make a mold according to the size of the designed disassembly-free stiffened composite formwork, brush the release agent on the surface of the mold, and place the mold on the vibrating table;

[0038] (2) Pour the cement slurry or commercial concrete material evenly into the mold, covering the bottom of the mold and 1mm higher than the bottom of the mold, that is, laying the bonding layer 1;

[0039] (3) Continue laying a layer of high-strength stainless steel wire mesh skeleton 4 on the bonding layer 1 described in step (2). After the skeleton is completed, it is covered with commercial concrete materials, and the pouring thickness is 12 mm;

[0040] (4) Repeat step (3) once;

[0041] (5) Lay another layer of stainless steel wire mesh skeleton 4, the diameter of the steel wire is 0.5 mm, the channel is square, the side length of the square is 10 mm, and then...

Embodiment 3

[0052] The method for using the non-disassembly stiffened composite template described in embodiment 1, its steps include:

[0053] (1) Splicing the non-disassembly-free stiffening composite formwork according to the shape of the main pouring structure to form a pouring formwork, and fixing it with a supporting device;

[0054] (2) 1-2 hours before the pouring of the main structure, spray and wet the non-disassembly stiffening composite formwork;

[0055] (3) The concrete of the main structure is poured in the pouring formwork formed by splicing the reinforced composite formwork without disassembly;

[0056] (4) After the main structure concrete is poured 3-28 days, the supporting device is removed to complete the pouring work.

[0057] Among them, before the above step (2), the inner surface 5 of the bonded layer of the non-removable stiffened composite template is cleaned; Side 5, use interface agent to strengthen the bonding performance of new and old concrete. The inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com