Comprehensive treatment method for recovered and used humic acid in garbage infiltration liquid

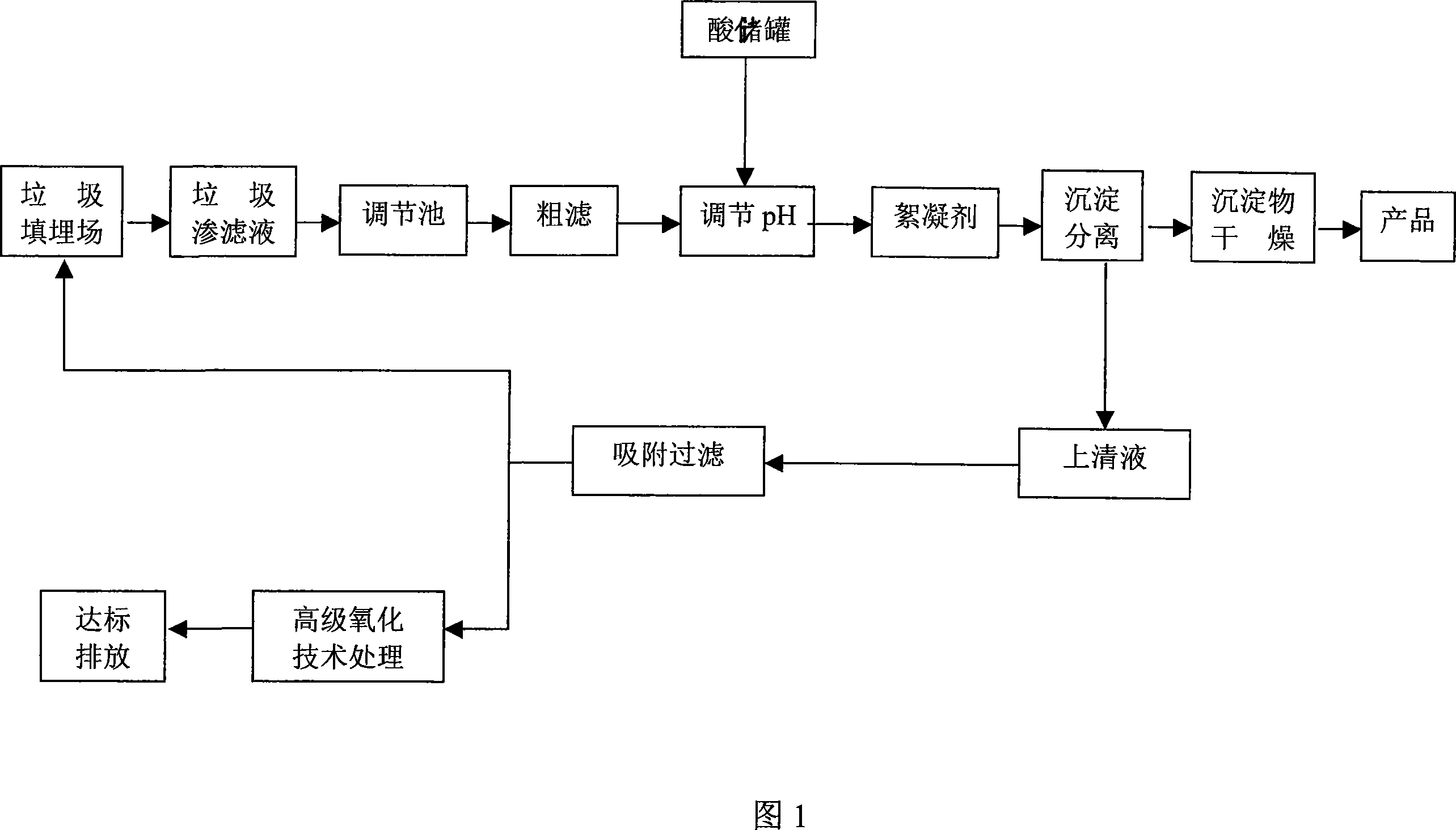

A technology for comprehensive treatment of landfill leachate, which is applied in the comprehensive treatment of humic acid recovery and utilization in landfill leachate, and in the field of landfill leachate treatment, can solve the problems of difficult to meet treatment requirements, high operating costs, waste of resources, etc., and achieve The effect of small investment, reduction of sewage charges, and mitigation of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 2 liters of landfill leachate, the flocculant is cationic polyacrylamide, hydrochloric acid

[0030] Landfill leachate: cationic polyacrylamide: hydrochloric acid = 1: 0.0002: 0.01

[0031] 2L landfill leachate is removed impurity through rough filtration, and measuring TOC and COD are 3402mg / L and 11500mg / L respectively; Put into beaker, add 20ml hydrochloric acid acidification at room temperature, adjust pH to be 4.0; Add 0.4ml 10% (by weight percentage) of cationic polyacrylamide, stirred at a stirring speed of 3000-4000r / min for 10min, settled for 80min, and centrifuged to obtain 24g (dry weight) of humic acid; determined by potassium dichromate oxidation method, its content was 91.5 %. The measured landfill leachate TOC and COD were 527.3mg / L and 1311mg / L respectively, and the removal rates reached 84.5% and 88.6% respectively.

[0032] The supernatant was adsorbed and filtered with magnesium-type modified slag to further remove pollutants in the leachate. After ...

Embodiment 2

[0035] Example 2 Landfill leachate is 8 liters, and the flocculant is polyferric sulfate, sulfuric acid

[0036] Landfill leachate: polyferric sulfate: sulfuric acid = 1: 0.0006: 0.004

[0037]8L landfill leachate is removed impurity through coarse filtration, and measuring TOC and COD are 3402mg / L and 11500mg / L respectively; Put into beaker, add 32ml sulfuric acid to acidify at room temperature, adjust pH to be 5.0; Add 4.8ml 10% (by weight Percentage) of polyferric sulfate, stirred at a stirring speed of 3000-4000r / min for 10min, settled for 80min, and centrifuged to obtain humic acid 99g (dry weight); measured by potassium dichromate oxidation method, its content was 91.5% . The measured landfill leachate TOC and COD were 483.1mg / L and 1219mg / L, and the removal rates reached 85.8% and 89.4%, respectively.

[0038] The supernatant is adsorbed and filtered with magnesium-type modified slag (preparation method is the same as in Example 1), further removes pollutants in the l...

Embodiment 3

[0040] Example 3 8 liters of landfill leachate, anionic polyacrylamide, phosphoric acid

[0041] Landfill leachate: anionic polyacrylamide: phosphoric acid = 1: 0.0004: 0.005

[0042] 8L landfill leachate is removed impurity through rough filtration, measure TOC and COD to be 3402mg / L and 11500mg / L respectively; Put into beaker, add 40ml phosphoric acid acidification at room temperature, adjust pH to be 5.5; Add 3.2ml 10% (by weight percentage) of anionic polyacrylamide, stirred at a stirring speed of 3000-4000r / min for 10min, settled for 80min, and centrifuged to obtain 98g (dry weight) of humic acid; determined by potassium dichromate oxidation method, its content was 90.5 %. The measured landfill leachate TOC and COD were 571.5mg / L and 1415mg / L, and the removal rates reached 83.2% and 87.7%, respectively.

[0043] The supernatant is adsorbed and filtered with magnesium-type modified slag (preparation method is the same as in Example 1), further removes pollutants in the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com