Process for recycling iron ore concentrate and ore sand from aluminum oxide red mud

A technique for recovering alumina and iron, applied in chemical instruments and methods, solid separation, magnetic separation, etc., can solve problems such as excessive content of Al2O3 and SiO2, failure to reach the grade that can be directly smelted, poor quality of iron concentrate, etc., to achieve The effect of saving construction and operating costs, reducing environmental pollution discharge fees, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

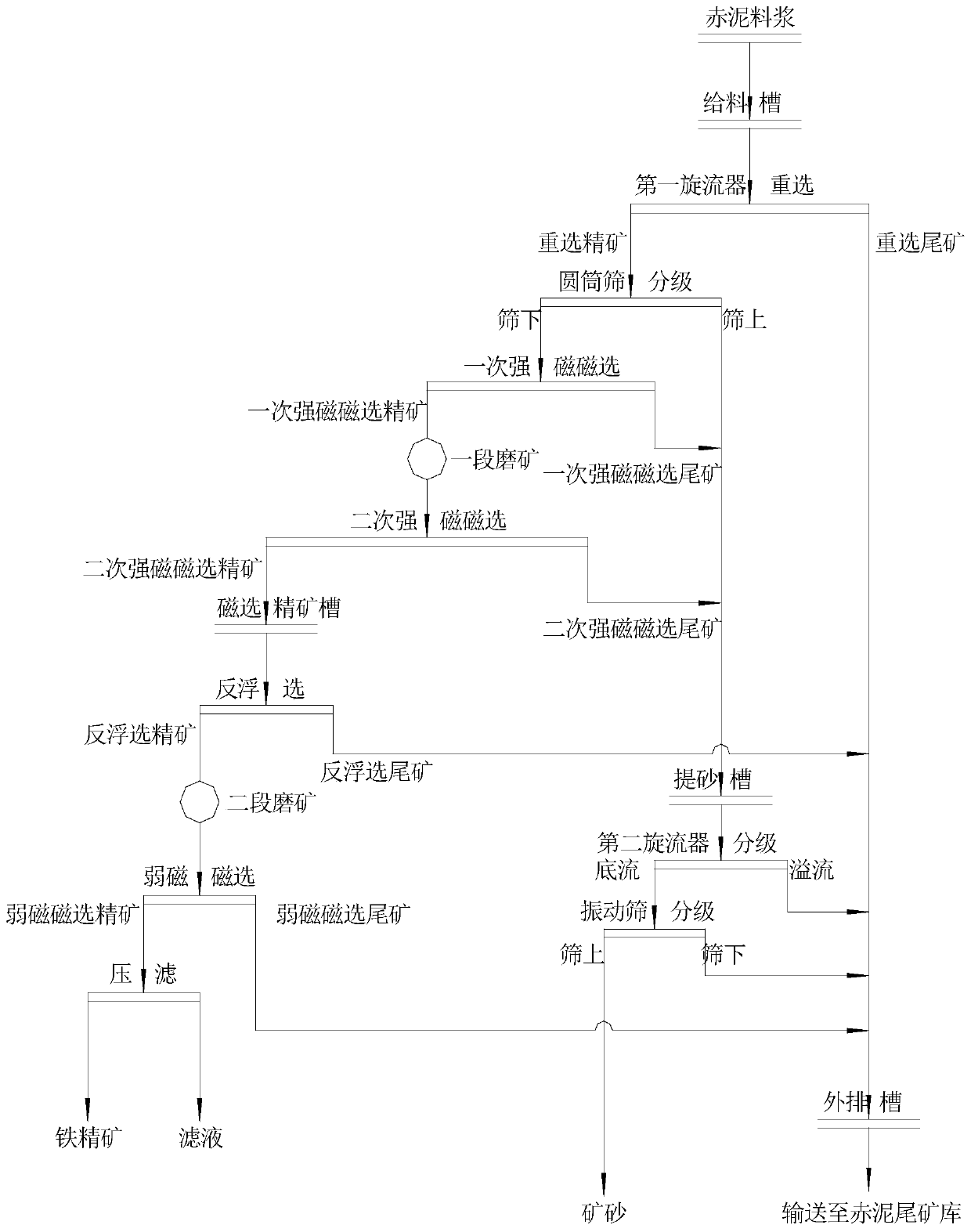

[0032] A process for recovering iron concentrate and ore from alumina red mud, the process comprises the following steps:

[0033] S1: Discharge the red mud slurry from the bottom flow of the last washing settling tank into the feeding tank and add water to pre-mix, and adjust the concentration of the pre-mixed red mud slurry to 25%, and then put it into the feeding tank The premixed red mud slurry is fed into the first cyclone for gravity separation treatment to obtain gravity separation concentrate and gravity separation tailings, and the gravity separation tailings are discharged into the outer discharge tank;

[0034] S2: Add the gravity-selected concentrate to a cylindrical sieve with a sieve hole of 1mm for grading treatment, then add the gravity-selected concentrate on the cylindrical screen to the sand extraction tank, and the The re-election concentrate is fed into the first strong magnetic separator for a strong magnetic separation, the magnetic field strength of the...

Embodiment 2

[0039] A process for recovering iron concentrate and ore from alumina red mud, the process comprises the following steps:

[0040] S1: Discharge the red mud slurry from the bottom flow of the last washing settling tank into the feeding tank and pre-mix with water, and adjust the concentration of the pre-mixed red mud slurry to 35%, and then put it into the feeding tank The premixed red mud slurry is fed into the first cyclone for gravity separation treatment to obtain gravity separation concentrate and gravity separation tailings, and the gravity separation tailings are discharged into the outer discharge tank;

[0041]S2: Add the gravity-selected concentrate to a cylindrical sieve with a sieve hole of 0.5mm for grading treatment, then add the gravity-selected concentrate on the cylindrical screen to the sand extraction tank, The re-selected ore concentrate is fed into the first strong magnetic separator for a strong magnetic separation, the magnetic field intensity of the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com