Preparation method of activated clay

An activated clay and active technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve problems such as affecting product quality, large acid and water consumption, and achieve simplified production process flow, simple production process, and improved production efficiency. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

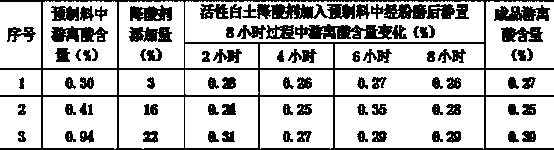

Embodiment 1

[0044] The first activated clay acid reducer consists of the following components by weight percentage: SiO 2 Content 36.12%, Al 2 o 3 Content 19.26%, Fe 2 o 3 content 8.58%, MgO content 9.86%, CaO content 10.26%, K 2 O content 4.0%, TiO 2 Content 1.2%, Na 2 The O content is 7.65%, other impurities are 3.07%, and the pH value is 7.2.

[0045] The preparation method of the first activated clay acid reducer comprises the steps:

[0046] Step 1: raw material selection, select 90 parts of gray attapulgite, 5 parts of bentonite, 3 parts of kaolinite, 1 part of illite and 1 part of quartz as basic raw materials to make granular materials;

[0047] Step 2: mixing the raw materials, mixing and stirring the gray attapulgite, bentonite, kaolinite, illite and quartz in the step 1 to form a mixture A;

[0048] Step 3: acidification treatment, the mixture A in the step 2 is acidified at room temperature with 3 parts of 38% hydrochloric acid and 15 parts of water to form mixture B, ...

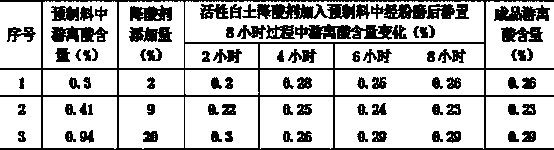

Embodiment 2

[0057] The second activated clay acid reducer consists of the following components by weight percentage: SiO 2 Content 59.62%, Al 2 o 3 Content 14.53%, Fe 2 o 3 content 2.82%, MgO content 9.17%, CaO content 5.26%, K 2 O content 0.17%, TiO 2 Content 2.39%, Na 2 The O content is 4.45%, other impurities are 1.59%, and the pH value is 8.4.

[0058] The preparation method of the second activated clay acid reducer comprises the steps:

[0059] Step 1: raw material selection, select 90 parts of gray-green attapulgite, 5 parts of bentonite, 2 parts of kaolinite, 2 parts of quartz and 1 part of dolomite as basic raw materials to make granular materials;

[0060] Step 2: mixing the raw materials, mixing and stirring the gray-green attapulgite, bentonite, kaolinite, quartz and dolomite in step 1 to form a mixture A;

[0061] Step 3: acidification treatment, the mixture A in the step 2 is acidified at room temperature with 5 parts of 36% hydrochloric acid and 15 parts of water to ...

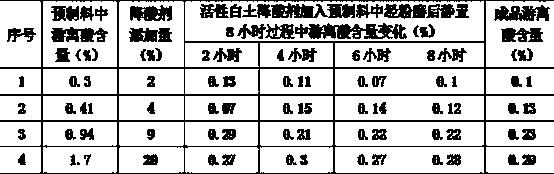

Embodiment 3

[0070] The third activated clay acid reducer is composed of the following components by weight percentage: SiO 2 Content 47.62%, Al 2 o 3 Content 9.53%, Fe 2 o 3 content 0.82%, MgO content 9.17%, CaO content 4.26%, K 2 O content 0.19%, TiO 2 Content 2.64%, Na 2 The O content is 3.45%, other impurities are 22.32%, and the pH value is 7.6.

[0071] The preparation method of the 3rd active clay acid reducer, comprises the steps:

[0072] Step 1: raw material selection, select 90 parts of off-white attapulgite, 5 parts of bentonite, 3 parts of kaolinite, 1 part of quartz and 1 part of feldspar as basic raw materials to make granular materials;

[0073] Step 2: mixing the raw materials, mixing and stirring the off-white attapulgite, bentonite, kaolinite, quartz and feldspar in step 1 to form a mixture A;

[0074] Step 3: acidification treatment, the mixture A in the step 2 is acidified at room temperature with 10 parts of 37% hydrochloric acid and 15 parts of water to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com