Wastewater Comprehensive Reuse System for Heating Boilers

A technology for heating boilers and wastewater, which is applied in water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc. , affecting the economic interests of enterprises and other issues, to achieve the effect of clean and efficient provision and reduction of sewage charges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

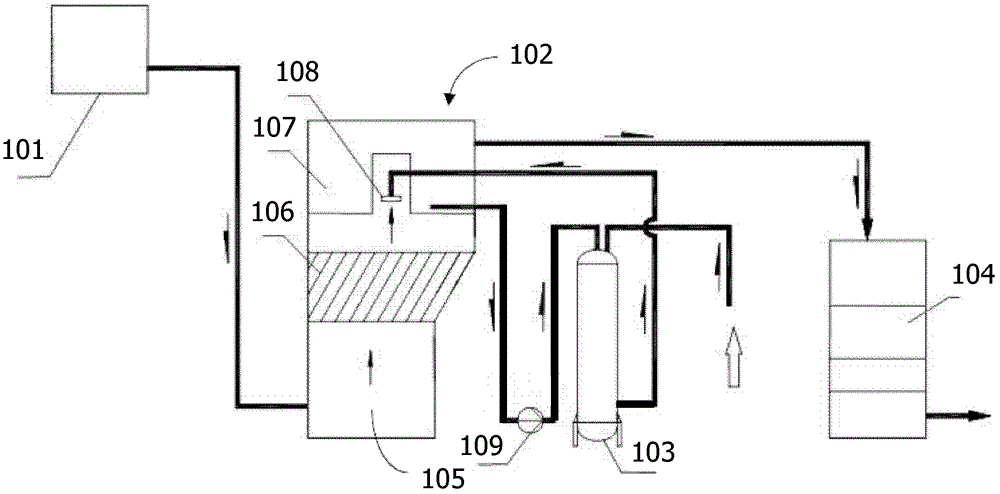

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] figure 1 Schematically shows the structure of a comprehensive waste water reuse system for heating boilers according to an embodiment of the present invention. Such as figure 1 As shown, the waste water comprehensive reuse system for heating boilers of the present invention may at least include: a waste water collection tank 101 , a sedimentation filter unit 102 , an automatic dosing device 103 and a concentration pool 104 . The sedimentation filtration unit 102 receives the wastewater from the wastewater collection tank 101 and performs sedimentation and filtration treatment on the wastewater.

[0024] especially in figure 1 In the illustrated embodiment, the sedimentation and filtration unit 102 may further include: a sedimentation tank 105 , an automatic alkali adding device 106 , a mixing tank 107 and a water purification tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com