Electroplating wastewater treatment recycling system

A technology of electroplating wastewater and wastewater, which is applied in the direction of metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high system operating cost, complex composition of discharged water, and high operation risk, so as to reduce wastewater discharge fees, The effect of large market prospects and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

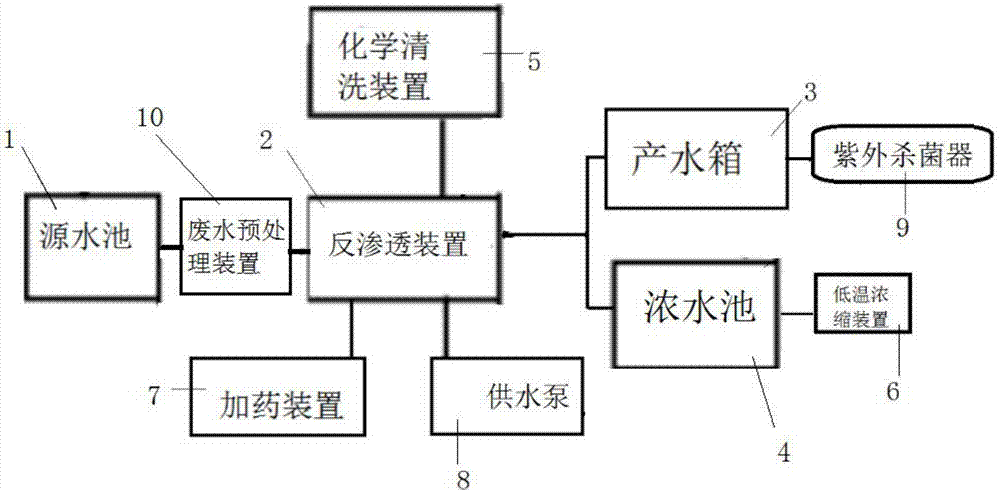

[0018] Example 1 This example discloses a treatment and recycling system for electroplating wastewater. The reverse osmosis wastewater treatment system includes a source water tank 1 and a reverse osmosis device 2 connected thereto. The source water tank and the reverse osmosis device A waste water pretreatment device 10 is also arranged between, and after the reverse osmosis device 2, two produced water tanks 3 and a concentrated water tank 4 are connected; the outer surface of the reverse osmosis device 2 is provided with an explosion-proof membrane, and the reverse osmosis device A check valve 6 is set at the water outlet and the water inlet. The volume of the produced water tank 3 is 50m 3 . The water production tank 3 is provided with a water inlet pipe, a water outlet pipe, an overflow pipe, an emptying pipe, a breathing pipe and an interface flange. There are two source water pools 1, the order is the first source water pool and the second source water pool, the volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com