Electroplating reclaimed water recycling and treating system

A treatment system and reclaimed water technology, applied in the field of water treatment, can solve the problems of excessive heavy metal substances, secondary pollution, unstable effluent quality, etc., and achieve the effects of protecting the environment, saving production costs, good economic benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

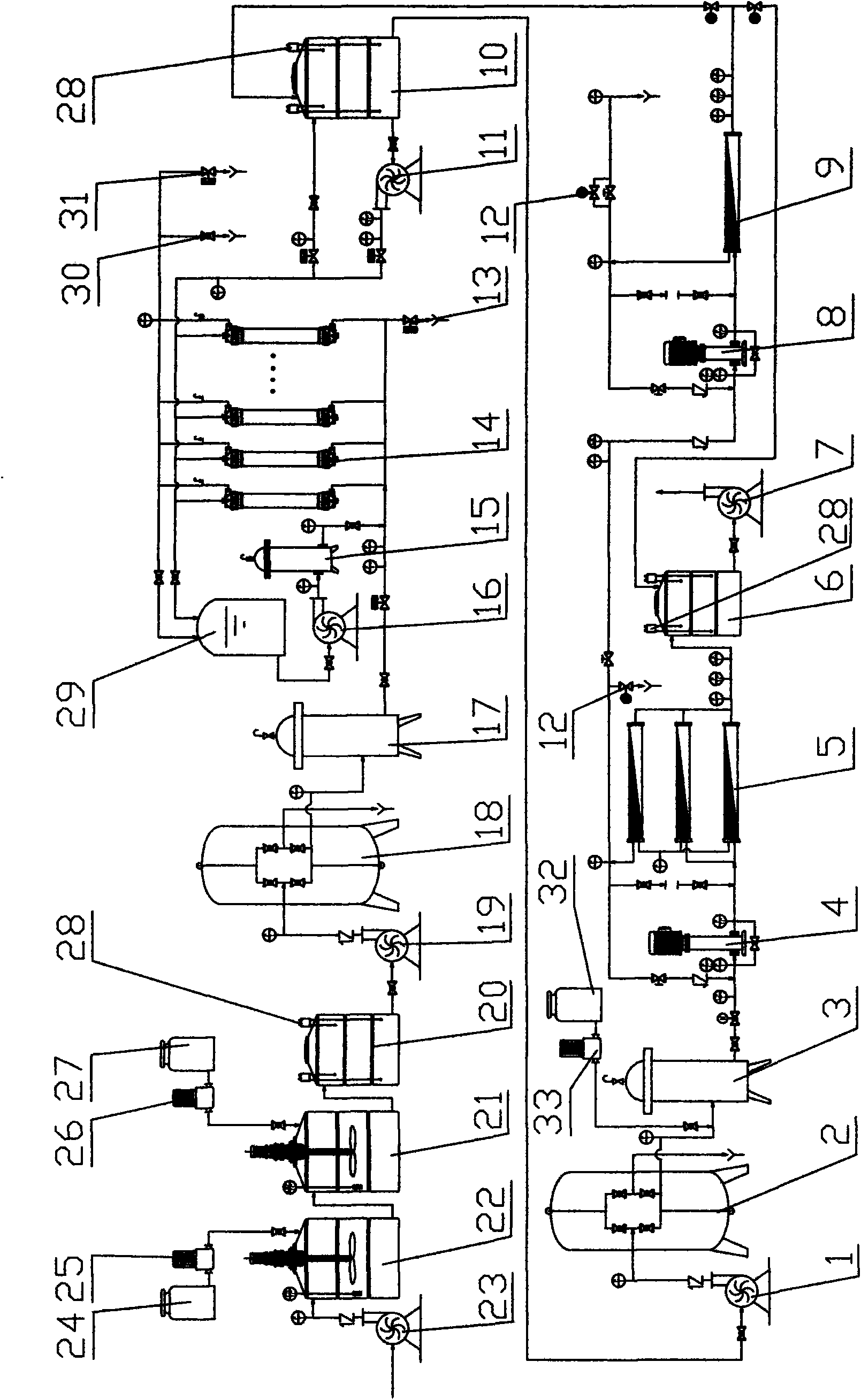

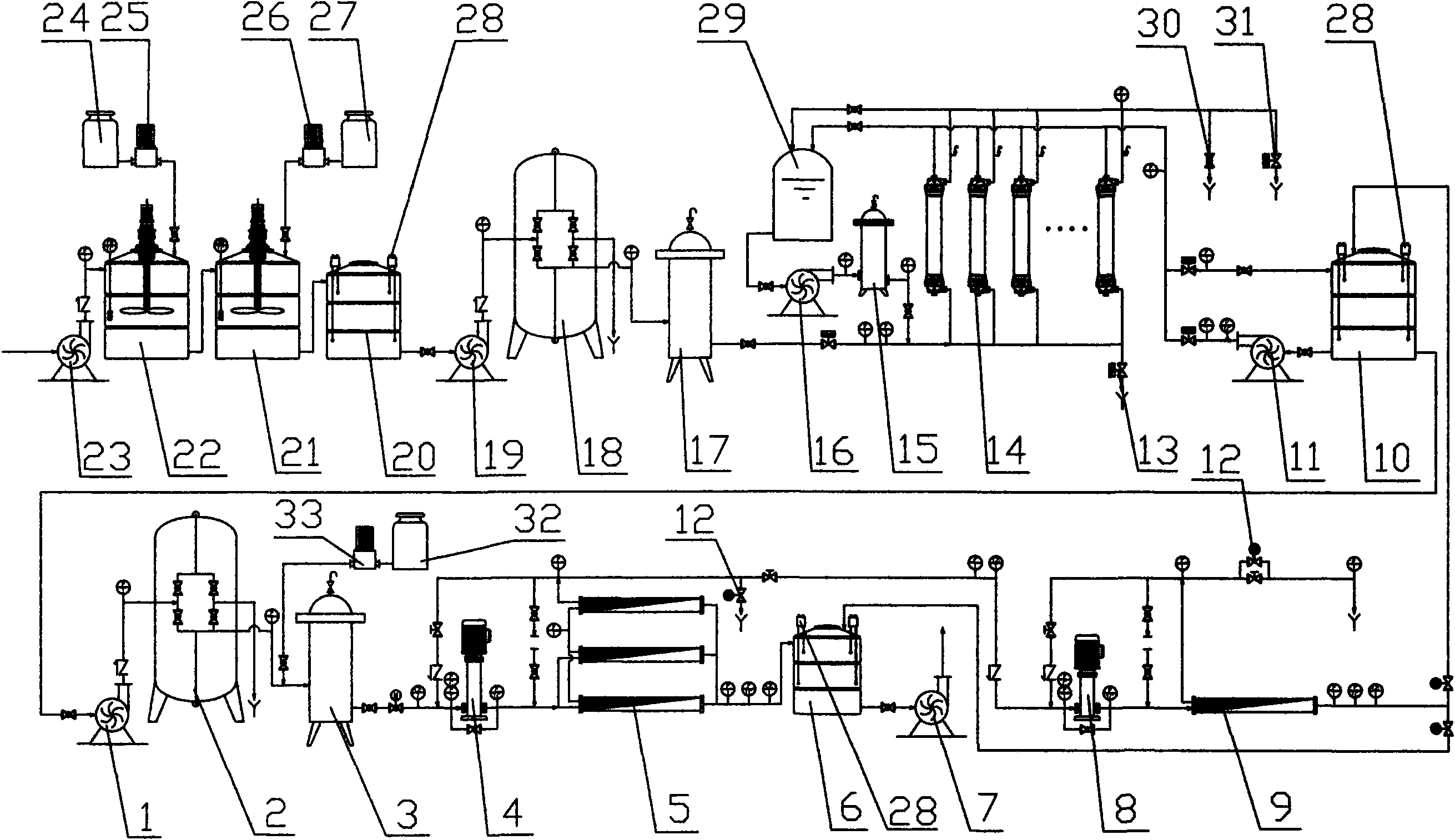

[0018] like figure 1 As shown, the electroplating water reuse treatment system includes a control device and an interconnected pre-regulation system, an ultrafiltration treatment system and a reverse osmosis treatment system. The pre-regulation system includes an interconnected ORP (oxidation-reduction potential) adjustment device and PH adjustment device, the ORP adjustment device includes ORP adjustment box 21, reducing agent metering pump 26, reducing agent tank 27 and agitator, the electroplating wastewater enters the clear water pool after being treated to reach the discharge standard, and is transported to the clean water tank by the lift pump 23 ORP adjustment box 21; the ultrafiltration treatment system includes an interconnected ultrafiltration water supply pump 19, a quartz sand filter 18, a precision filter 17, an ultrafiltration membrane assembly 14, an ultrafiltration backwash pump 11 and an ultrafiltration water tank 10, The pH adjustment device includes a pH adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com