Method and device for deacidifying hot flue gas

A technology of hot flue gas and deacidification, applied in the field of heat treatment, can solve problems such as treating the symptoms but not the root cause, increasing equipment costs, etc., to achieve the effect of improving efficiency and reducing the probability of corrosion and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

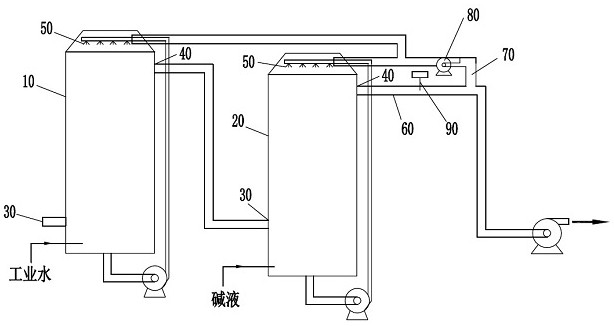

[0024] Such as figure 1 As shown, the device for deacidification of hot flue gas according to the present invention has a main body of a precooling tower 10 and a deacidification tower 20, the precooling tower 10 is arranged before the deacidification tower 20, and the precooling tower 10 Industrial water is used for spray cooling, and the deacidification tower 20 is deacidified and cooled with lye.

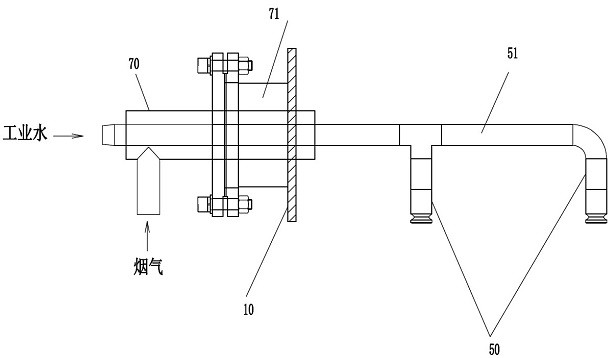

[0025] The sides of the precooling tower 10 and the deacidification tower 20 are both provided with a flue gas inlet 30 and a flue gas outlet 40 . The acidic hot flue gas enters the precooling tower 10 at first. A spray head 50 is arranged on the top of the pre-cooling tower 10 . The hot flue gas is in countercurrent contact with the fine liquid particles coming out of the shower head 50 to realize the cooling of the hot flue gas, and the easily soluble gas in the hot flue gas is also removed at the same time. The innovation of the present invention is: the deacidified flue ga...

Embodiment 2

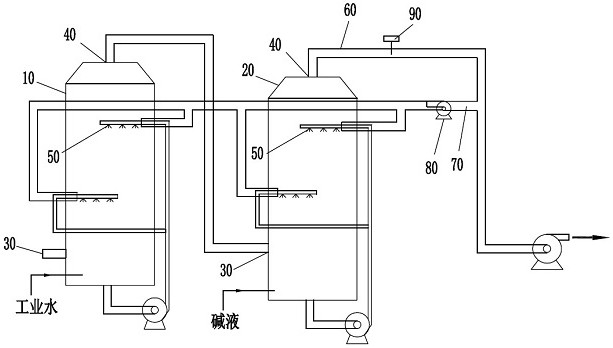

[0030] Such as figure 2 Shown, the difference between this embodiment and embodiment 1 is:

[0031] 1. The spray heads 50 in the pre-cooling tower 10 and the deacidification tower 20 are no longer a single layer, but are arranged in two layers, including an upper layer spray head and a lower layer spray head, and the lower layer spray head is located at the flue gas inlet 30 on one side. The staggered setting of the upper spray head and the lower spray head makes the hot flue gas move in an S shape in the precooling tower 10 and the deacidification tower 20, which is conducive to increasing the lateral flow of the hot flue gas and making the cooling and deacidification of the hot flue gas more efficient. full.

[0032] 2. The flue gas outlet 40 of the precooling tower 10 and the deacidification tower 20 is no longer arranged on the side of the precooling tower 10 and the deacidification tower 20, but is arranged on the top of the precooling tower 10 and the deacidification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com