Combined purification system for waste incineration smoke and technology of combined purification system

A technology for incinerating flue gas and purifying system, applied in the field of environmental engineering, can solve the problems such as the lack of better control of the concentration of smoke and dust, the difficulty of ensuring continuous control of the concentration of dust emissions, and the increase of absorbent consumption and fly ash generation. , to achieve the effect of saving thermal energy consumption, reducing engineering investment and operating costs, and saving resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

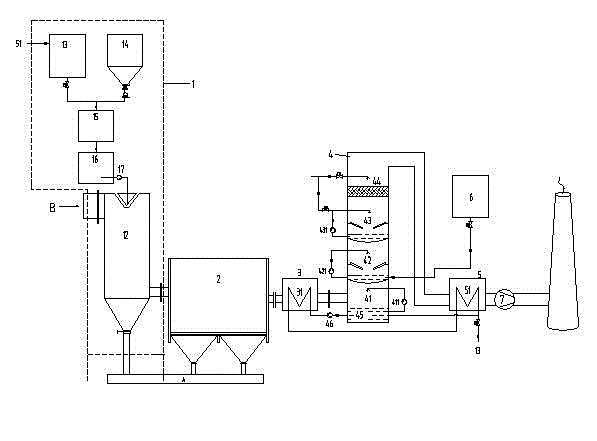

[0058] As shown in the figure, a combined incineration flue gas purification system disclosed by the present invention is set between the waste incineration (waste heat) boiler outlet B and the induced draft fan 7, including a spray deacidification system 1, a dust collector 2, a flue gas Cooler 3, flue gas scrubber 4, flue gas reheating device 5.

[0059] The spray deacidification system 1 includes a spray device, a reaction tower 12 , a water tank 13 , an absorbent raw material bin 14 , an absorbent preparation tank 15 , an absorbent storage tank 16 , and an absorbent delivery pump 17 .

[0060] The flue gas cooler 3 includes a heat exchange component 1 31 .

[0061] The flue gas scrubber 4 includes a water-eluting acid section 41, a neutralization absorption section 42, a cleaning section 43, a dehumidification section 44, a total sump 45, and a drainage pump 46. The neutralization absorption section 42 and the cleaning section 43 are respectively provided with Circulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com