Method of using sodium bicarbonate for deacidifying incineration flue gas and realizing zero discharge of sewage

A technology for incinerating flue gas and baking soda, which is applied in separation methods, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high-salt wastewater sprayed into the quench tower to accumulate salt, affecting the stable production of the process, etc., to solve the problem of wastewater Dispose of problems, improve production economic benefits, and achieve the effect of zero discharge of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

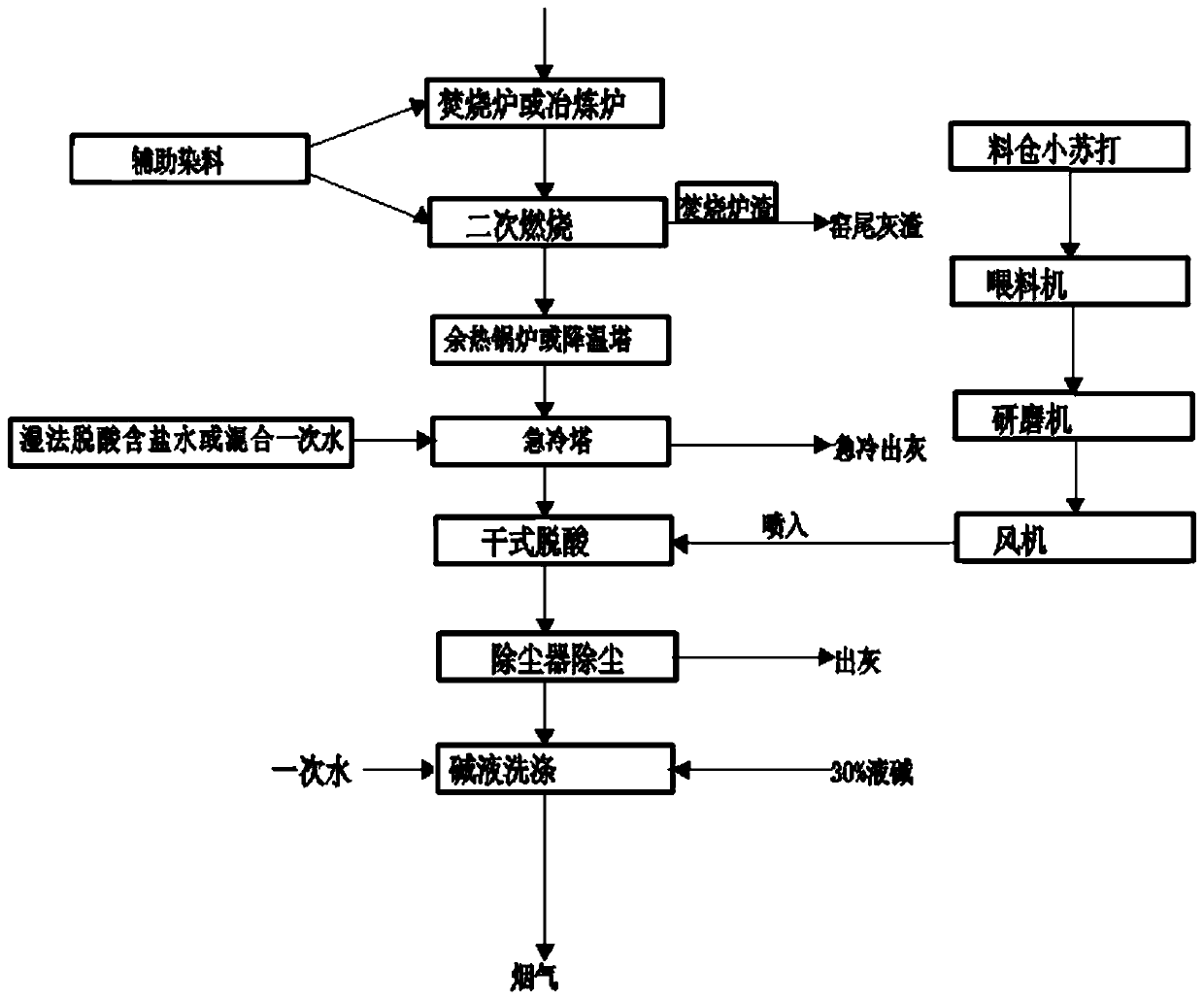

[0053] A method for using baking soda to deacidify incineration flue gas and realize zero discharge of sewage, comprising steps:

[0054] After the high-temperature flue gas enters the quenching tower, the temperature suddenly drops below 200°C under the action of water or brine. Discharge after the dust collector.

[0055] The ground baking soda is ground to 20 μm baking soda powder by an air grinder, and sprayed quantitatively and timely into the flue gas according to the requirements of working conditions.

[0056] Described incineration flue gas comprises the steps:

[0057] 1) When the high-temperature flue gas has no waste heat boiler, the cooling tower is used to cool the flue gas to above 500°C;

[0058] 2) The flue gas is rapidly cooled to below 200°C;

[0059] 3) The air grinder grinds the baking soda;

[0060] 4) Baking soda dry deacidification;

[0061] 5) Activated carbon adsorption;

[0062] 6) Filter dust removal;

[0063] 7) Step 4)-Step 6) are combined ...

Embodiment 2

[0067] A method for using baking soda to deacidify incineration flue gas and realize zero discharge of sewage, comprising steps:

[0068] After the high-temperature flue gas enters the quench tower, the temperature suddenly drops below 200°C under the action of water or salt water. At this time, the ground sodium bicarbonate is sprayed in time for deacidification. When the high-salt wastewater is produced by deacidification method, and it is difficult to discharge the high-salt wastewater into the sewage treatment plant and the environment, a salt inhibitor is added to the high-salt wastewater, and after mixing evenly, the uniformly mixed high-salt wastewater is sprayed back into the Quenching tower.

[0069] The ground baking soda is ground to 20 μm baking soda powder by an air grinder, and sprayed quantitatively and timely into the flue gas according to the requirements of working conditions.

[0070] Described incineration flue gas comprises the steps:

[0071] 1) When th...

Embodiment 3

[0091] A method for using baking soda to deacidify incineration flue gas and realize zero discharge of sewage, comprising steps:

[0092] After the high-temperature flue gas enters the quenching tower, the temperature suddenly drops below 200°C under the action of water or salt water, and when the high-salt wastewater is difficult to discharge into the sewage treatment plant and the environment, a salt inhibitor is added to the high-salt wastewater and mixed After uniformity, the homogeneously mixed high-salt wastewater is sprayed back into the quenching tower, and at this time, the ground sodium bicarbonate is sprayed in time for deacidification.

[0093] The ground baking soda is ground to 20 μm baking soda powder by an air grinder, and sprayed quantitatively and timely into the flue gas according to the requirements of working conditions.

[0094] Described incineration flue gas comprises the steps:

[0095] 1) When the high-temperature flue gas has no waste heat boiler, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com