Atomizing core and atomizer applying same

An atomization core and atomizer technology, applied in the field of atomizers, can solve the problems of small atomization area, slow oil supply, and easy suspension of heating wire, etc., and achieve large atomization area, fast oil supply speed, and optimal The effect of the smoking experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

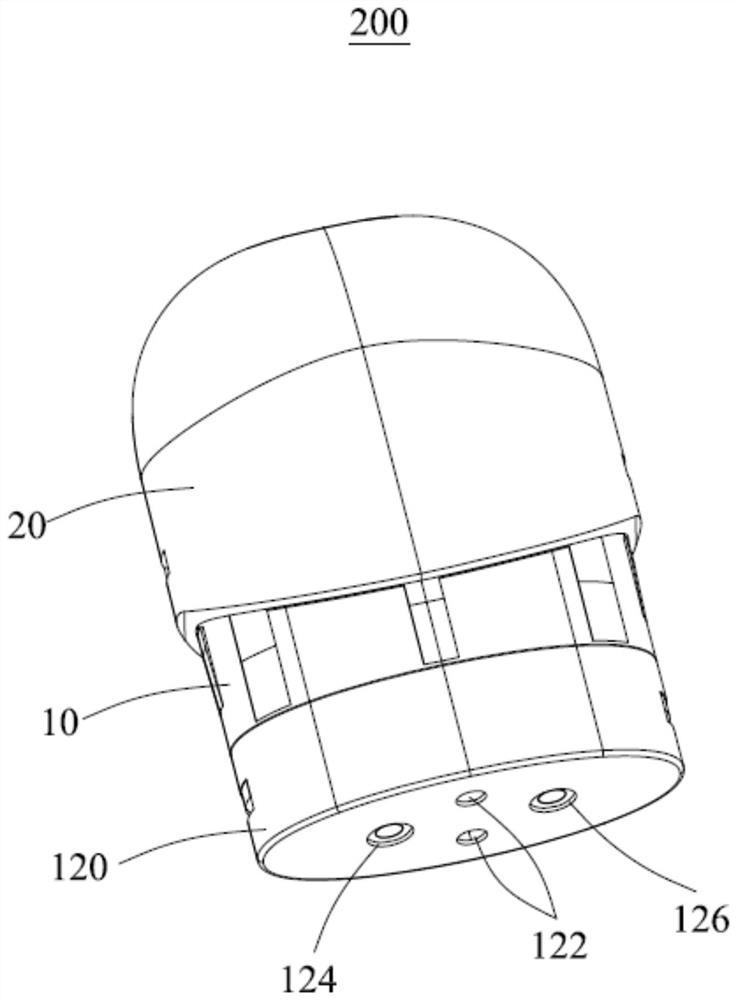

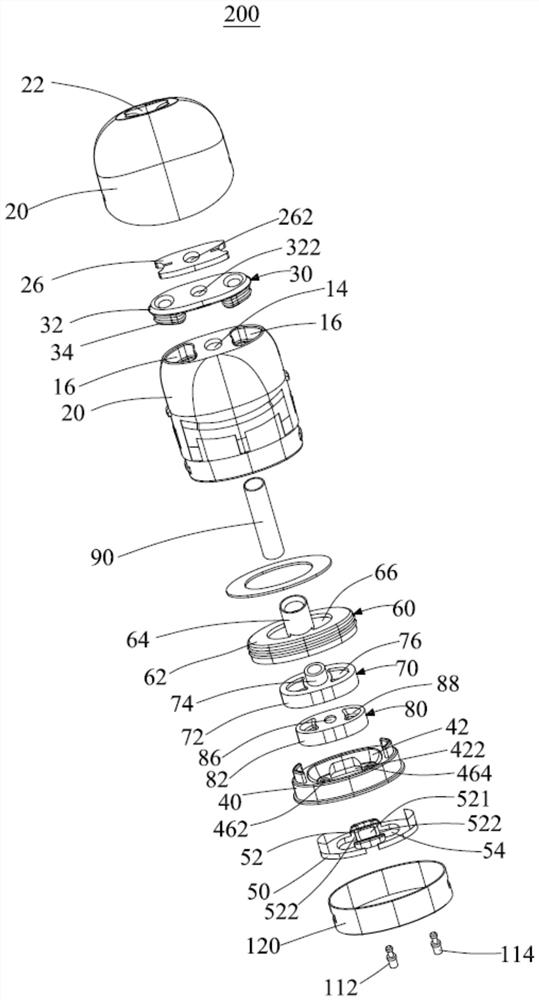

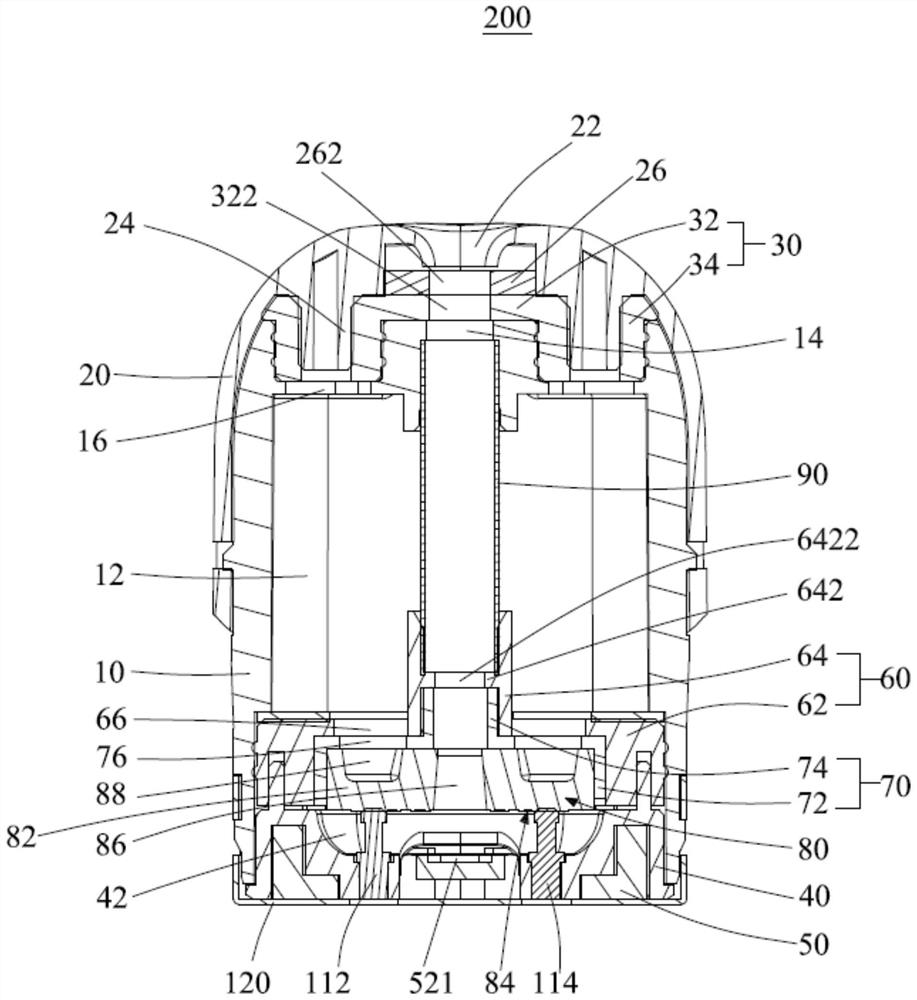

[0084] see figure 1 , the present embodiment provides an atomizer 200 , including an oil cup 10 , a suction nozzle 20 fitted to the first end of the oil cup 10 , and a cylindrical protective shell 120 fitted to the second end of the oil cup 10 .

[0085] see Figure 1 to Figure 3 , the atomizer 200 also includes a breather tube 90 installed in the oil cup 10 , a seal 60 , a spacer 70 and an atomizing core 80 .

[0086] The sealing member 60 includes a tubular first connecting portion 64 and a cylindrical first body 62 extending outward from an end of the first connecting portion 64 . The outer periphery of the first body 62 is in sealing connection with the inner wall of the oil cup 10, for example, by setting a sealing ring on the outer wall of the first body 62, and the sealing ring is tightly pressed to the inner wall of the oil cup 10 so as to realize the connection with the inner wall of the oil cup 10. Sealed connection. The inside of the first connection portion 64 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com