Hydraulic pump

A technology of hydraulic pumps and plunger pumps, which is applied in the direction of pumps, pump devices, liquid displacement machines, etc. It can solve the problems of slow oil supply, unstable oil pressure, and insufficient pressure, and achieve fast oil supply and stable oil pressure , the effect of sufficient pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

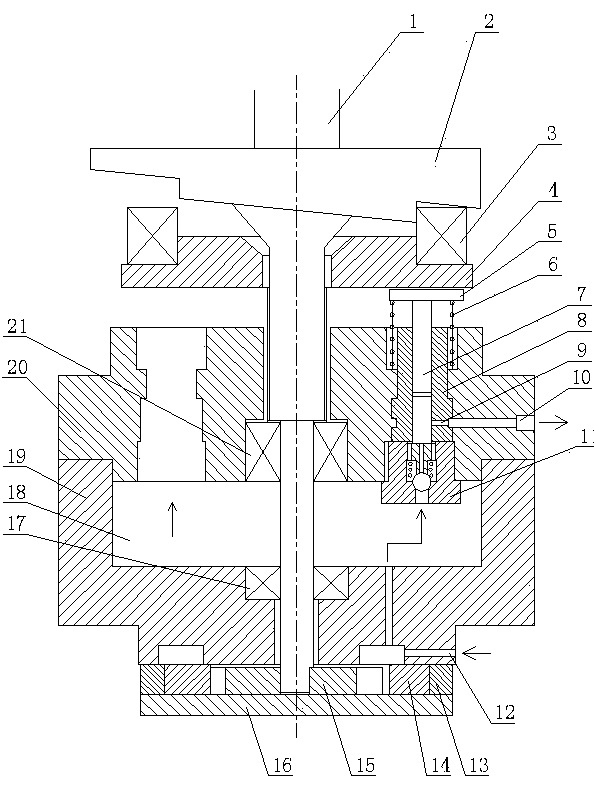

[0008] Such as figure 1 As shown, it is a hydraulic pump, including a transmission shaft 1, an inclined-plane step 2 is provided on the transmission shaft 1, and the lower end surface of the inclined-plane step 2 is an inclined plane. Also set bearing block 4, plunger pump body 20, gear pump body 19 and external gear 15 on transmission shaft 1, bearing block 4 is arranged on the below of slope step 2, and plane bearing 3 is set on bearing block 4. The plunger pump body 20 is set on the transmission shaft 1 through the needle bearing 21, the plunger pump body 20 is set under the bearing seat 4, and three plunger sleeves 8 are arranged in the plunger pump body 20 along the circumferential direction, each column The plunger 7 is respectively inserted in the plug sleeve 8, and the upper end of each plunger 7 is connected with a big end step 5 respectively, and each big end step 5 is respectively arranged between the bearing seat 4 and the plunger pump body 20, and each plunger Sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com