Cut-off non-return differential pressure valve

A differential pressure valve and non-return technology, which is applied in the direction of valve devices, engine components, mechanical equipment, etc., can solve the problems that the unit cannot be exhausted outside, unfavorable equipment reliability, and poor equipment appearance, etc., and achieves small resistance loss and excellent structure. Simple, effective cooling performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

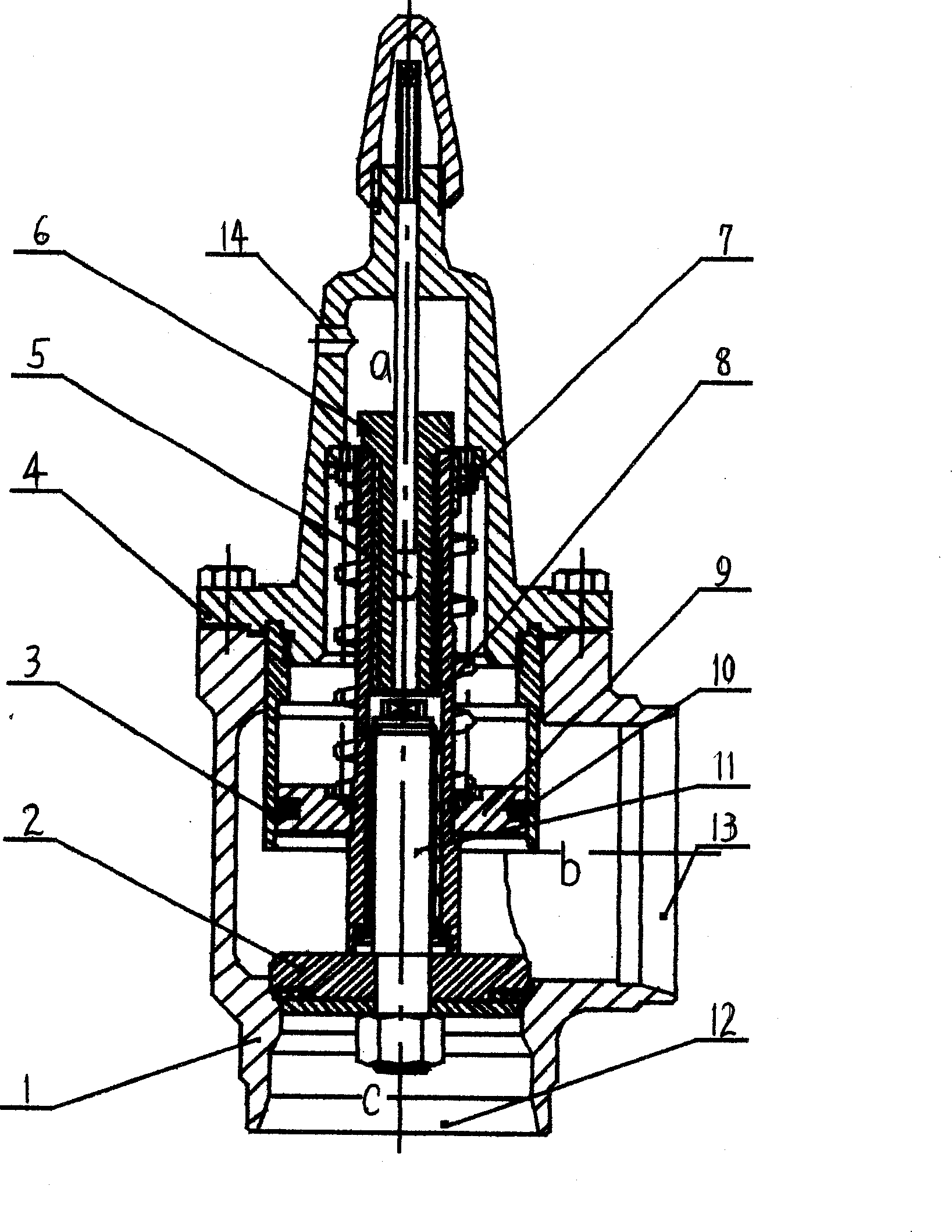

[0015] Embodiment: a cut-off check differential pressure valve (see accompanying drawing), which is provided with a valve seat 1, the lower end of the valve seat 1 is provided with a cavity 12, the cavity 12 is connected to c cavity, and the right side is provided with a cavity 13, Cavity port 13 is connected to cavity b, valve seat 1 is connected to valve body 4, valve body 4 is provided with cavity port 14, cavity port 14 is connected to cavity a, valve body 4 is connected to cylinder liner 3, and cylinder liner 3 is provided with piston 9, piston 9 There is a sealing ring 10 on the top, the piston 9 can move back and forth in the cylinder liner 3, the piston 9 is inlaid with soft sealing material, the piston 9 is connected to the piston rod 8, the piston rod 8 is covered with a spring 7, and the upper part of the piston rod 8 is connected Position screw 6, the limit screw 6 is provided with an adjustment rod 5, the adjustment rod 5 can move up and down in the limit screw 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com