Spray head suitable for perfluorohexanone

A perfluorohexanone and sprinkler technology, applied in fire rescue and other directions, can solve the problems of spray coverage of dead corners, unfavorable fire extinguishing speed and effect, and unsatisfactory atomization, and achieve the effect of large atomization area and no dead corner coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

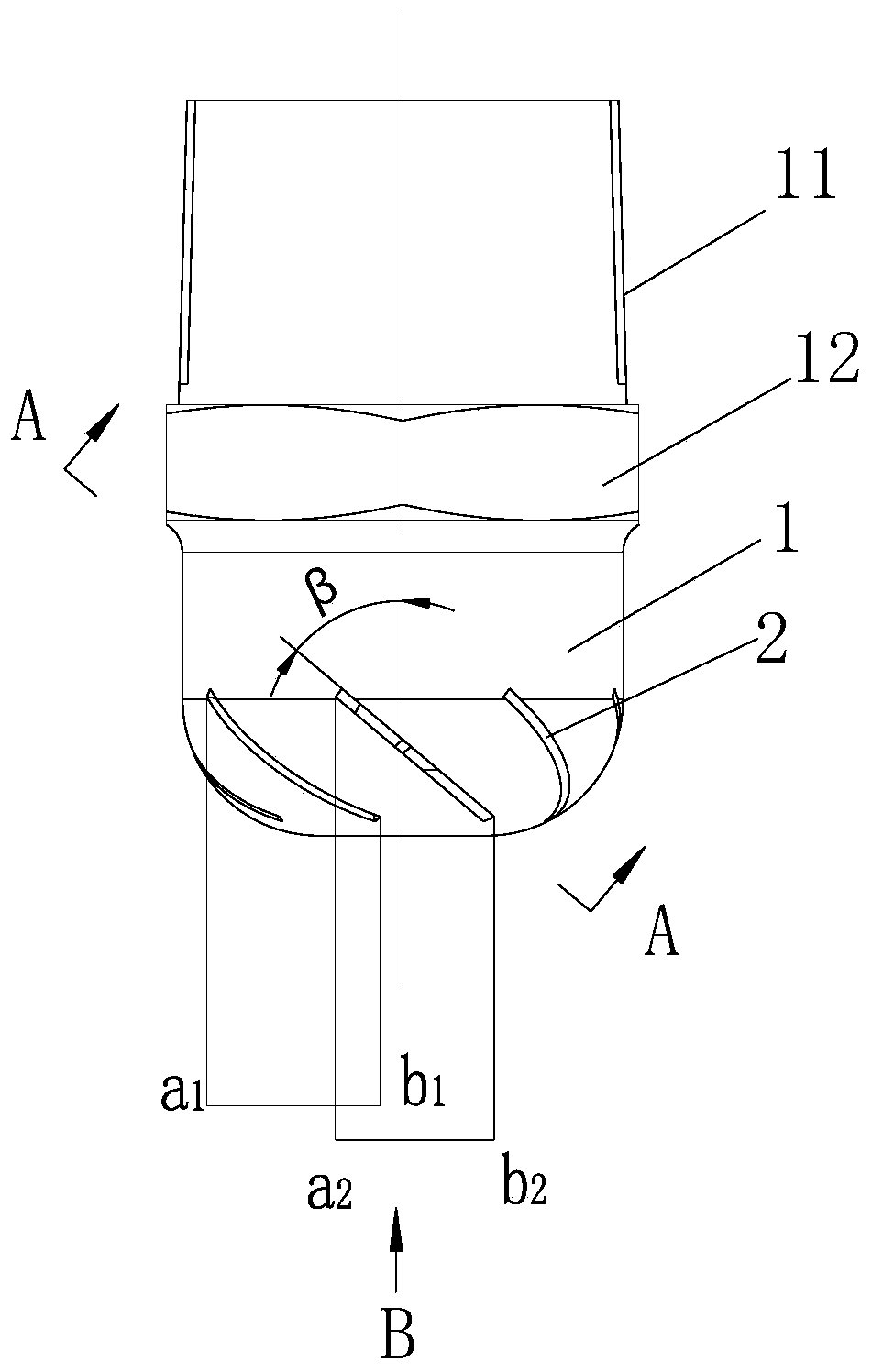

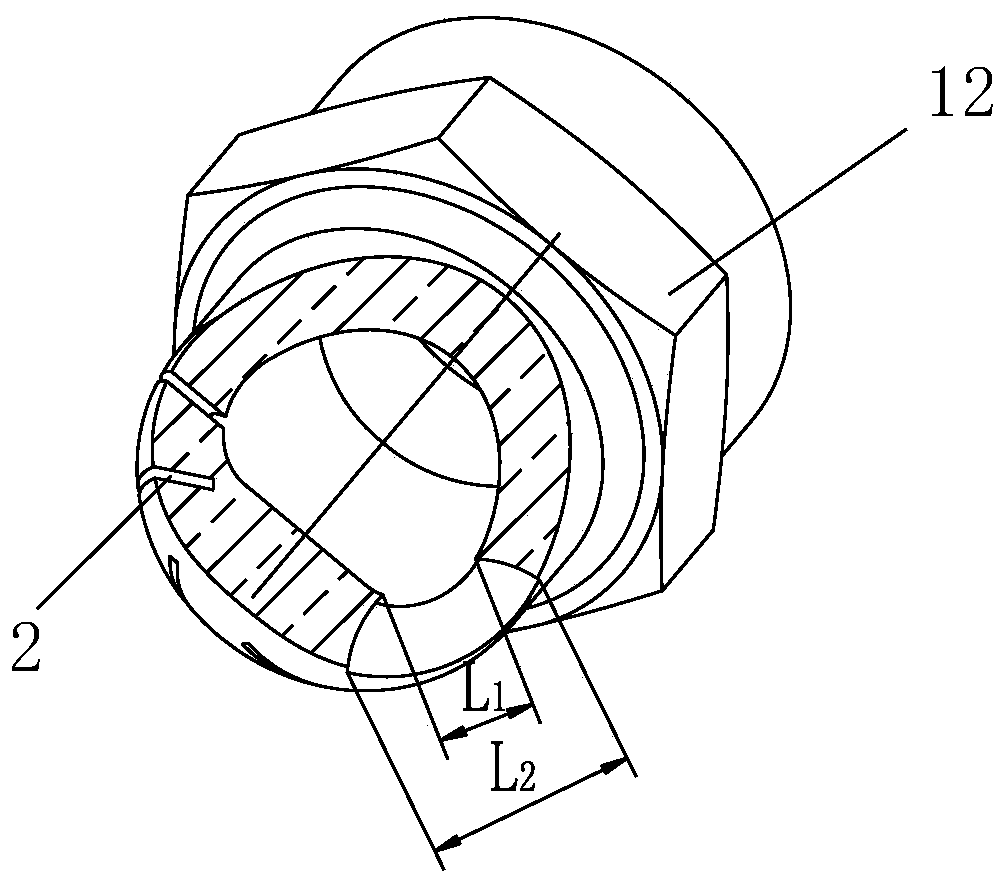

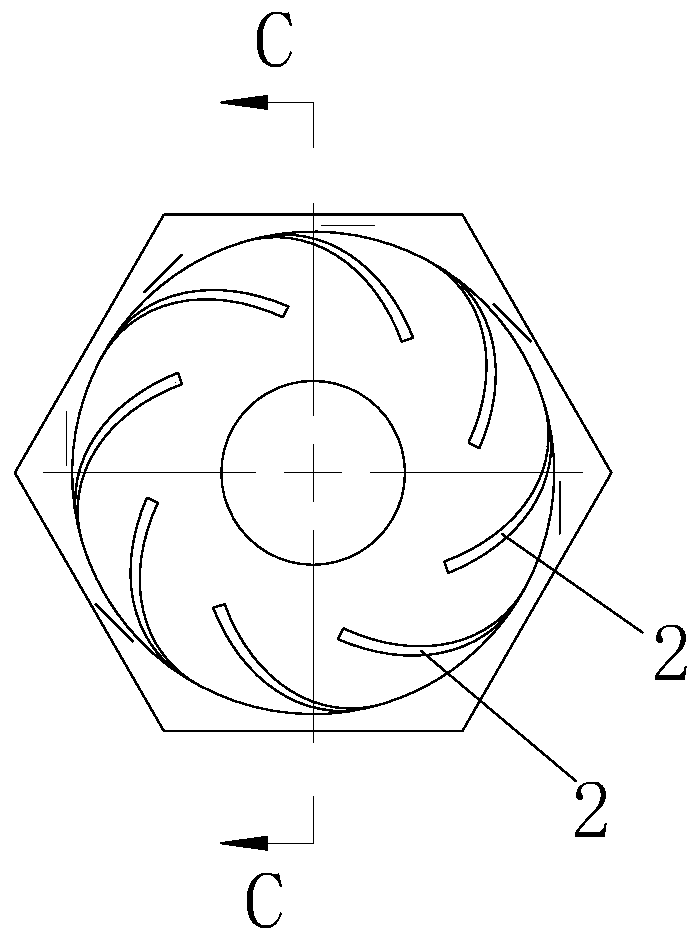

[0018] Figure 1 to Figure 5 Shown is an embodiment of the spray head suitable for perfluorohexanone according to the present invention. The spray head suitable for perfluorohexanone in this embodiment includes a housing 1, and a plurality of spray slots 2 are provided on the housing 1. The spray slots 2 are arranged along the circumferential direction, the spray slots 2 are arranged obliquely, and the projections of two adjacent spray slots 2 in the horizontal plane overlap from end to end (attached figure 1 in line segment a 1 b 1 Right end and line segment a 2 b 2 The left end overlaps), the inclination angle of spray slot 2 is β, then 0°<β≤90°.

[0019] The spray head suitable for perfluorohexanone adopts spray slots 2 arranged obliquely for spraying. Compared with spraying with spray holes, the agent can obtain a larger atom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com