Gas-liquid two-phase mist generator and generation method thereof

A generator and fine mist technology, applied in the direction of chemical instruments and methods, mixing methods, dissolution, etc., can solve the problems of high water quality requirements, small load area, easy to block nozzles, etc., achieve uniform atomization distribution, increase fog The effect of reducing the area and reducing the size of the fog particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

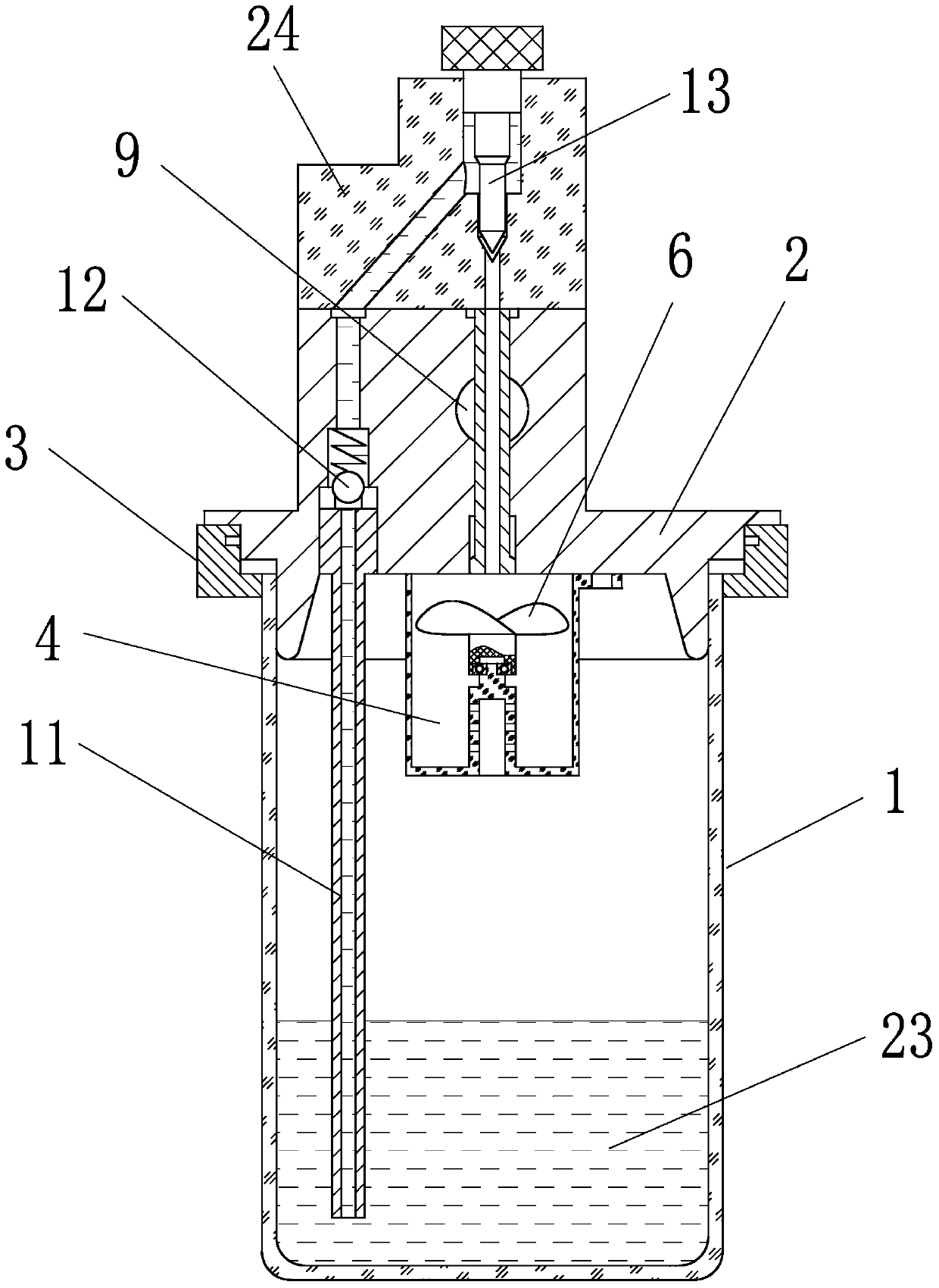

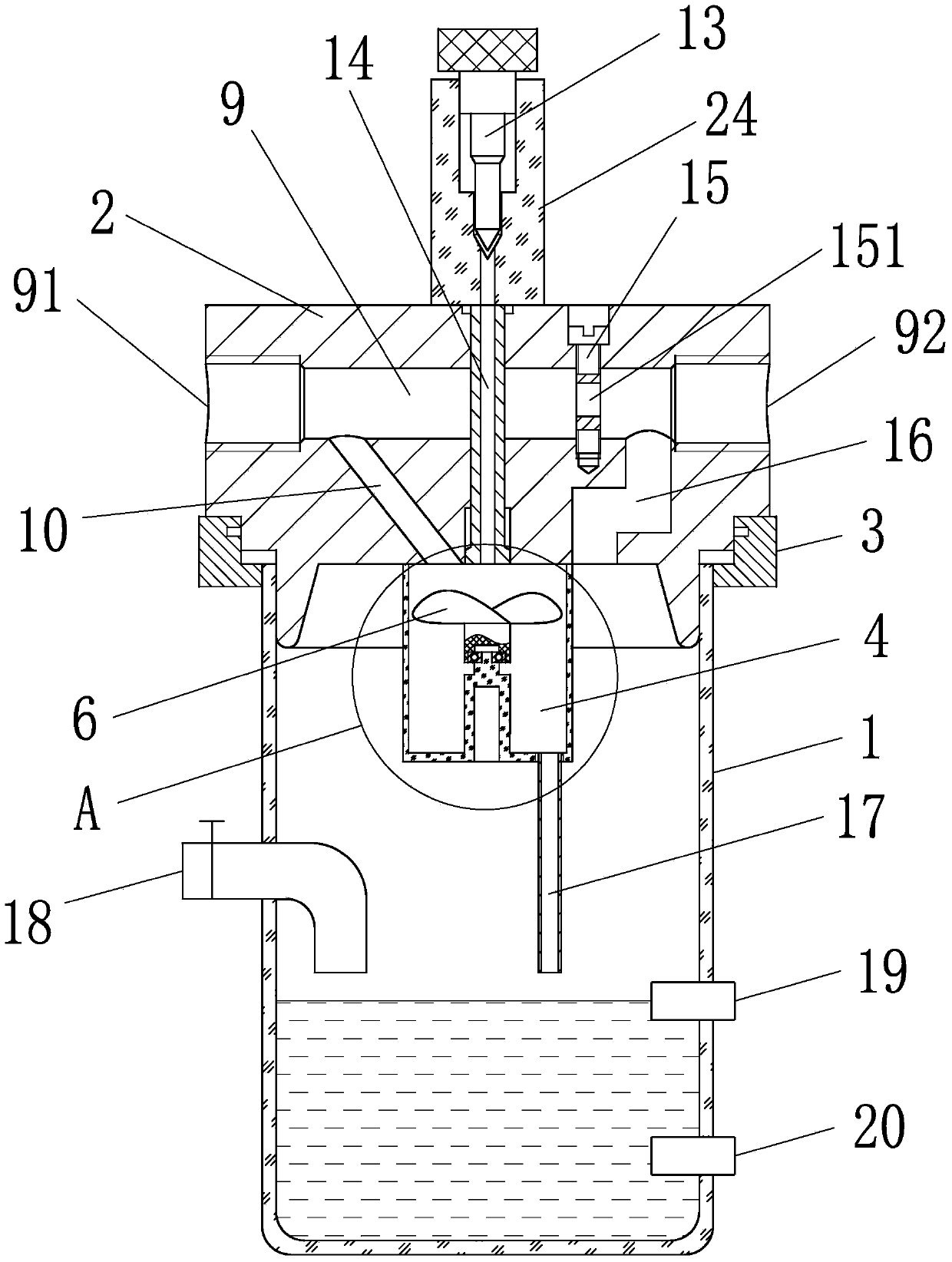

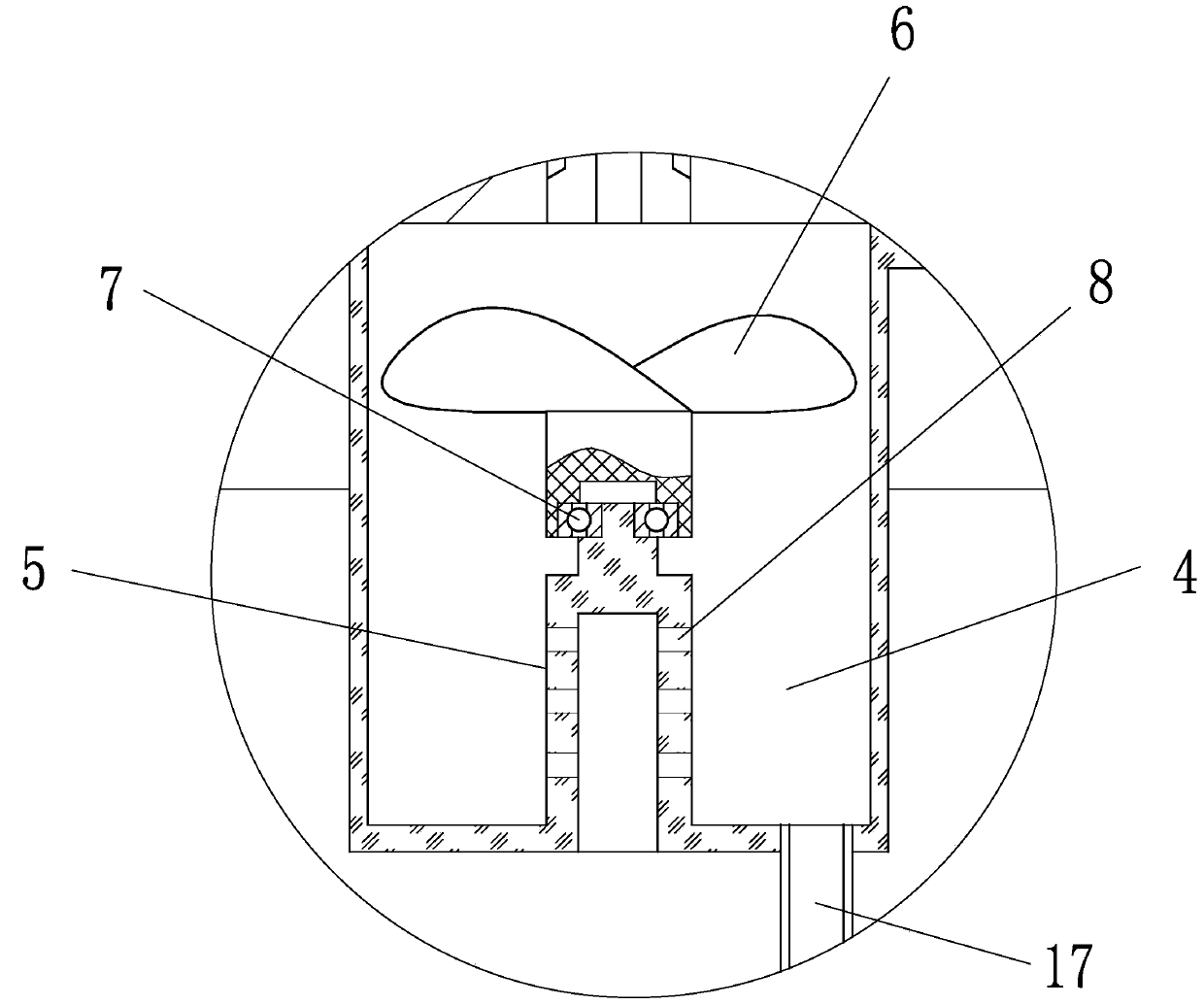

[0025] Embodiment 1: as figure 1 , 2 As shown, a gas-liquid two-phase fine mist generator includes a liquid storage tank 1 and a valve cover 2 sealed on the upper end of the liquid storage tank 1, and a clamping sleeve 3 is fastened at the connection between the liquid storage tank and the valve cover , the lower end of the clamping sleeve 3 is in interference fit with the upper edge of the liquid storage tank 1 , and the upper end of the clamping sleeve 3 is in interference fit with the edge of the valve cover 2 . The upper part of the side wall of the liquid storage tank 1 has a liquid filling port 18, and the lower part of the side wall of the liquid storage tank is equipped with an upper liquid level sensor 19 and a lower liquid level sensor 20 at longitudinal intervals, and the upper liquid level sensor 19 and the lower liquid level sensor 20 pass through The controller is connected with the liquid filling port 18 . An air guide channel 9 runs through the valve cover 2 ...

Embodiment 2

[0028] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 4 As shown, the bottom surface of the primary atomization chamber 4 is a guiding slope 25 , and the guiding slope 25 is inclined towards the mouth of the liquid return pipe 17 . The bottom surface of the primary atomization chamber is a guiding slope. Since the guiding slope is inclined towards the mouth of the liquid return pipe, the non-atomized liquid produced in the primary spraying chamber is kept toward the liquid return pipe along the guiding slope, which is convenient for the primary fog The liquid in the atomization chamber is discharged to avoid residual liquid in the primary atomization chamber.

Embodiment 3

[0029] Embodiment 3: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 5 As shown, the center of the breaking wheel 6 is integrally connected with a top 21. The top 21 is conical. The needle valve and the drip tube 14 are all coaxial.

[0030] Set the top at the axis of the breaking wheel, and the top is vertically corresponding to the adjusting needle valve. After the adjusting needle valve adjusts the liquid entering the oil suction pipe into liquid droplets, the liquid drops vertically on the top of the rotating breaking wheel. The tip, the tip of the tip penetrates the droplet and splits the droplet into several water petals. The water petals are broken up by the breaking wheel, and the droplet is split by the top, and then broken up by the breaking wheel, so that the droplet can achieve Split and disperse for many times, so that the mist particles of the atomized liquid are finer, and the liquid and gas are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com