Spray gun spray nozzle capable of realizing minuteness atomization

A spray gun and fine technology, applied in spray devices, liquid spray devices, etc., can solve the problems of restricting the use of advanced environmental protection coatings, restricting coating quality, coating loss, etc., achieving smaller diameter, easier operation, and improved coating quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

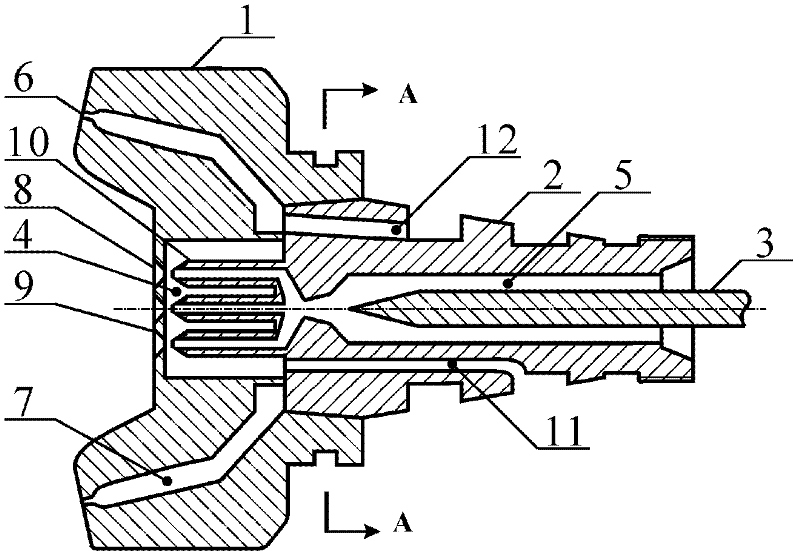

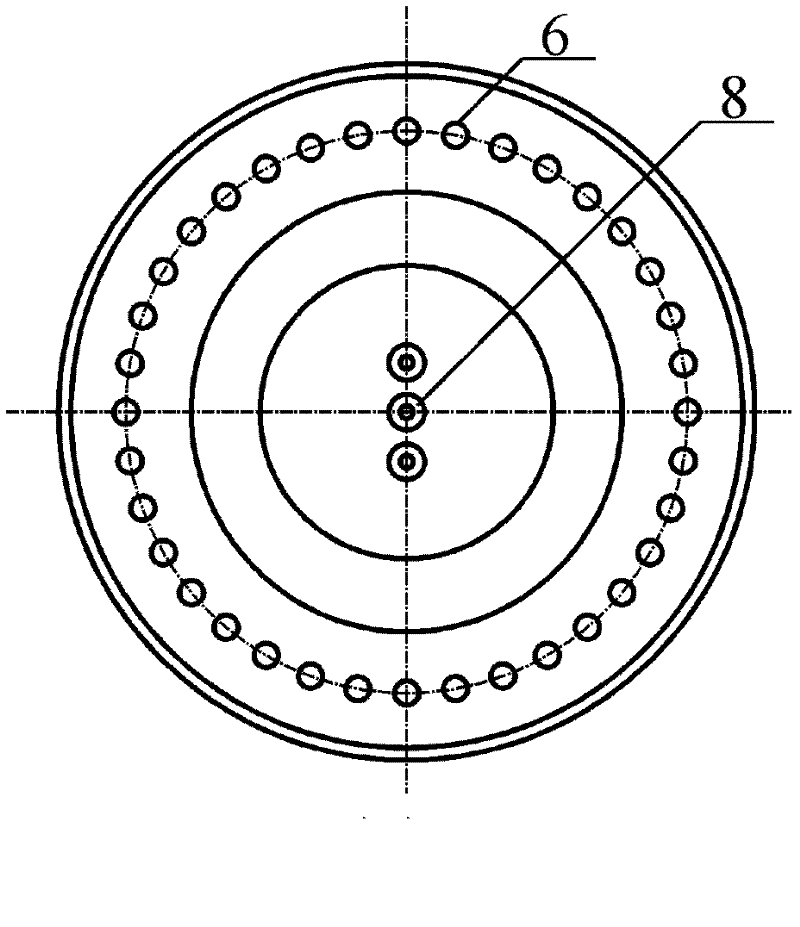

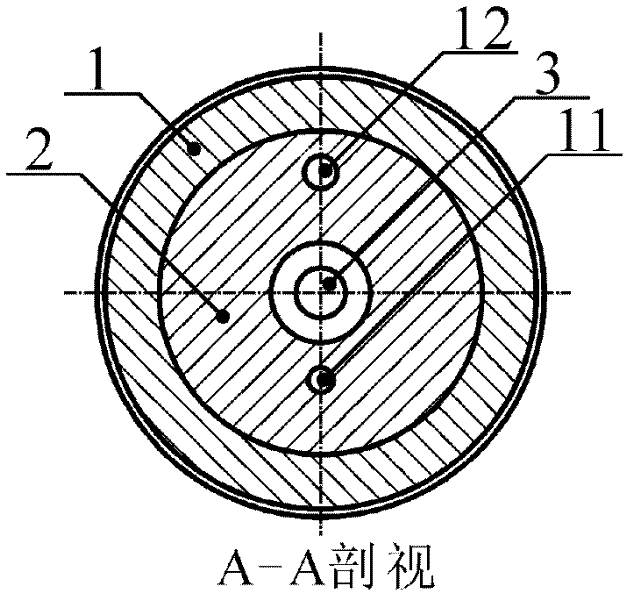

[0029] This embodiment is an implementation of a spray gun head capable of fine atomization. figure 1 It is a schematic diagram of the longitudinal section structure of Embodiment 1 of the present invention, figure 2 yes figure 1 side view, image 3 yes figure 1 A-A cross-sectional schematic diagram of the structure.

[0030] Such as figure 1 , figure 2 and image 3Shown: In this embodiment, the device is composed of an air cap 1, a feeder 2 and a valve needle 3; a high-pressure air chamber 4 is formed between the air cap 1 and the feeder 2, and the valve needle 3 extends into the feeder The inner wall of the device 2; the central part of the air cap 1 is a thin plate 9, and there are three discharge holes 8 on the thin plate 9, all of which are circular table tops that increase along the material output direction, arranged in a row; the outer edge of the air cap 1 is provided with a The air curtain spout 6 is a Venturi nozzle; the feeder 2 is provided with a paint pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com