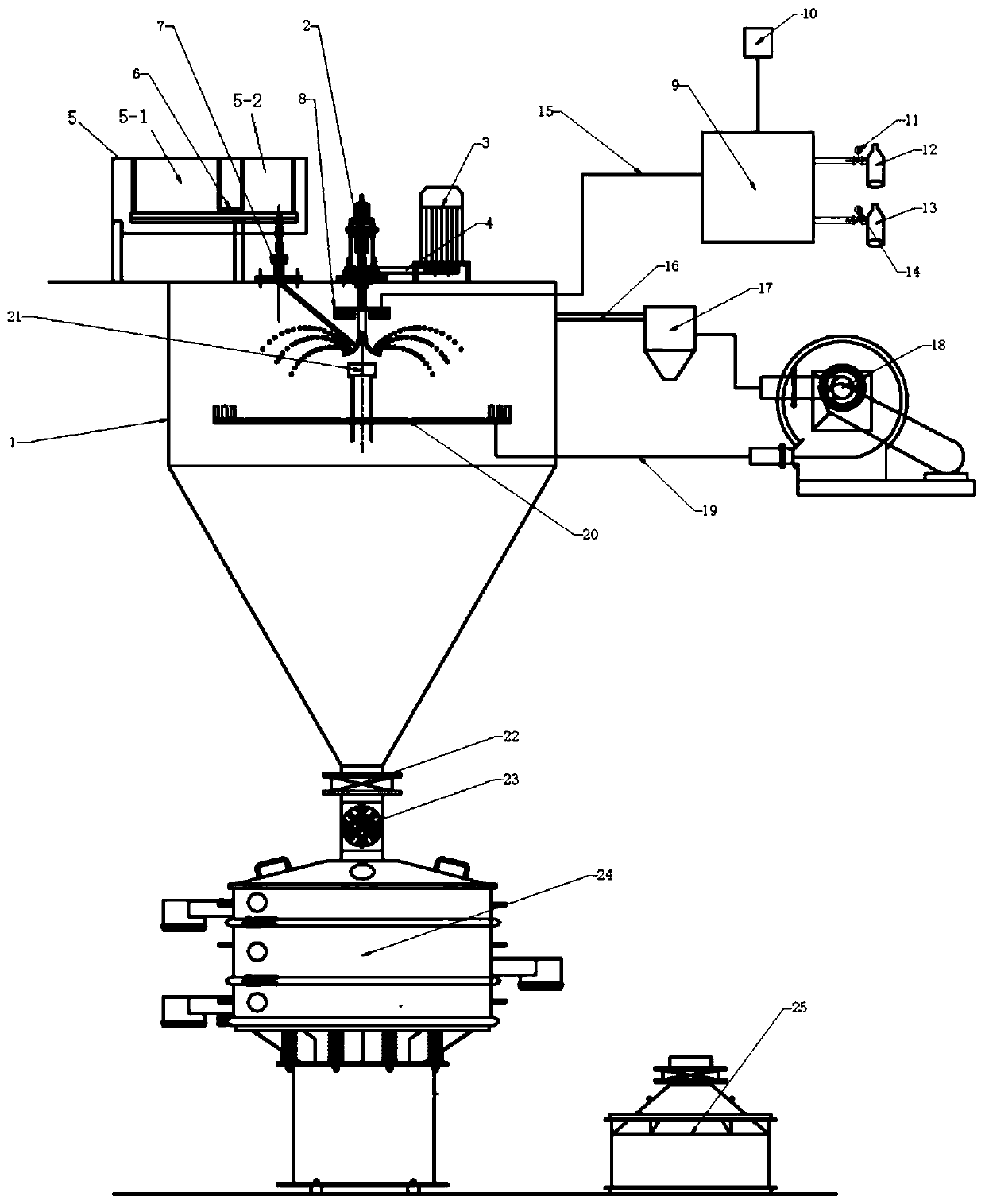

Equipment and method for preparing high-quality spherical welding powder

A high-quality, spherical technology, applied in the equipment and field of preparing high-quality spherical solder powder, can solve the problems of difficult control of sphericity of the surface structure of solder powder, complicated installation and maintenance, low atomization efficiency, etc., and achieve enhanced ultrasonic atomization efficiency , the temperature is uniform and pure, and the effect of improving the atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

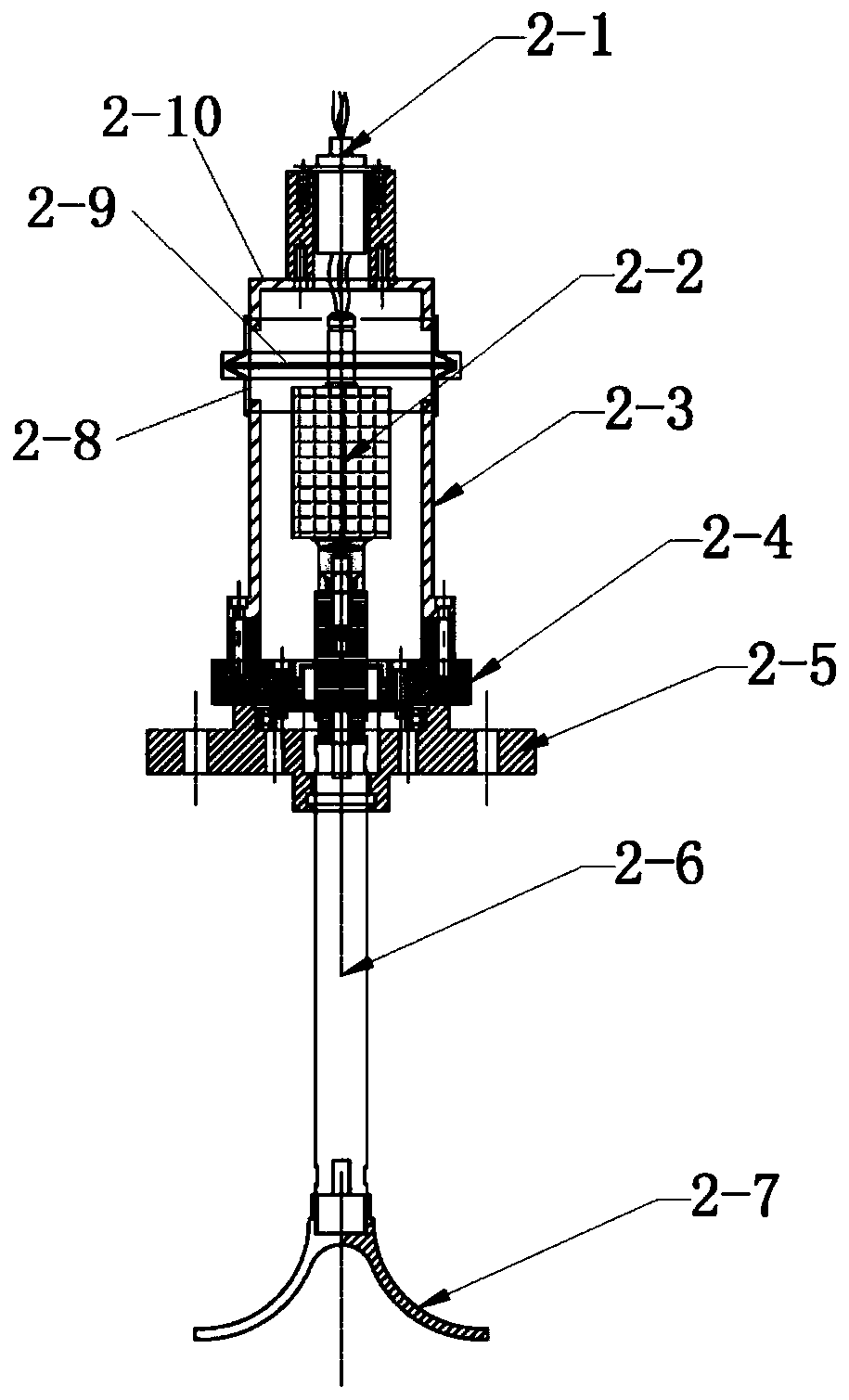

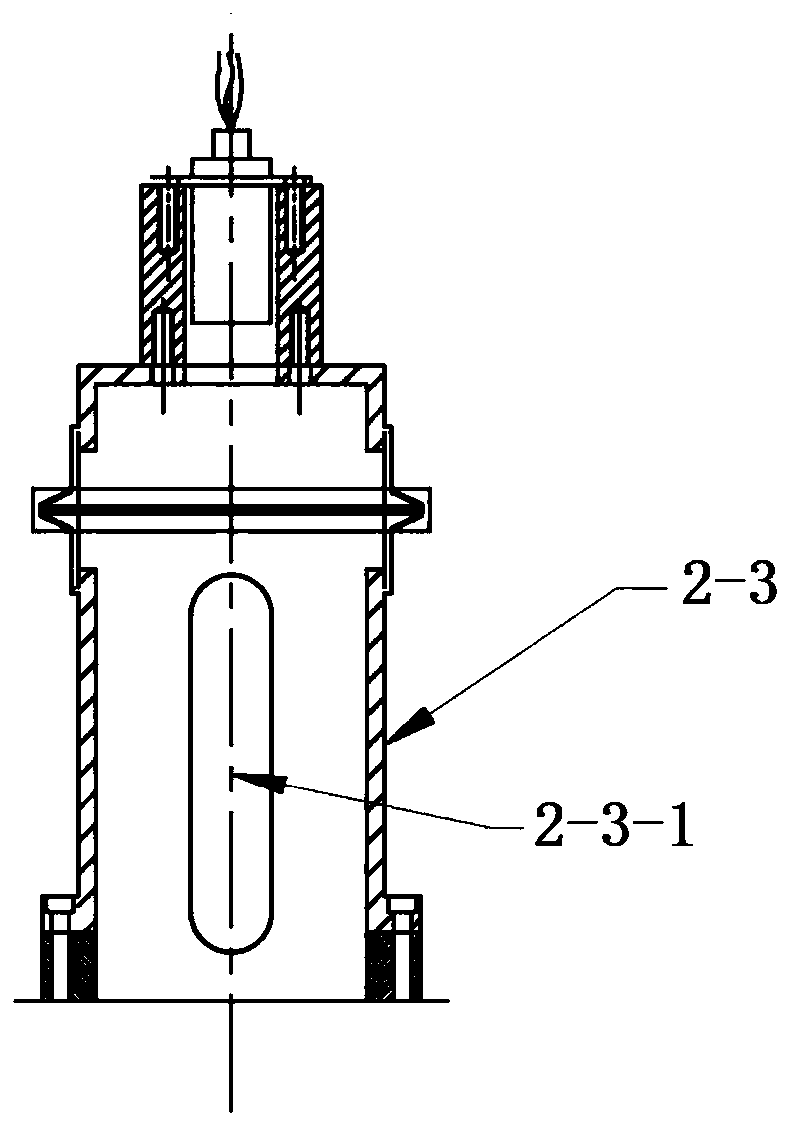

Method used

Image

Examples

example 3

[0051] Production example 3, producing Pb92.5Ag2.5Sn5.0 spherical solder powder. Feed the Pb92.5Ag2.5Sn5.0 alloy ingot, set the temperature of the molten material holding furnace and the feeding pipe at 380°C to 390°C, set the temperature of the infrared radiation heater at 350°C, set the frequency of ultrasonic atomization at 49.6khz, and set the rotation speed of the rotating motor The oxygen content control value of the oxygen content analyzer is set to 110ppm, the control value of the gas heating and cooling thermostat is 50°C, the speed of the circulating fan is set to 680rpm, and the production of Pb92.5Ag2.5Sn5.0 powder adopts a discontinuous screening process , that is, use a turnover tank to collect the atomized powder and then feed it to an ultrasonic sieving machine for screening. The average sphericity of the Pb92.5Ag2.5Sn5.0 powder produced by this process is >0.95, the surface of the powder is smooth without obvious defects, and the oxygen content <100ppm, no sat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com