Mini combustor

A micro combustion and combustion chamber technology, applied in the field of construction machinery, can solve the problems of large size, low integration, and inconvenient movement of the burner, and achieve the effects of small size, increased atomization area, and fast ignition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

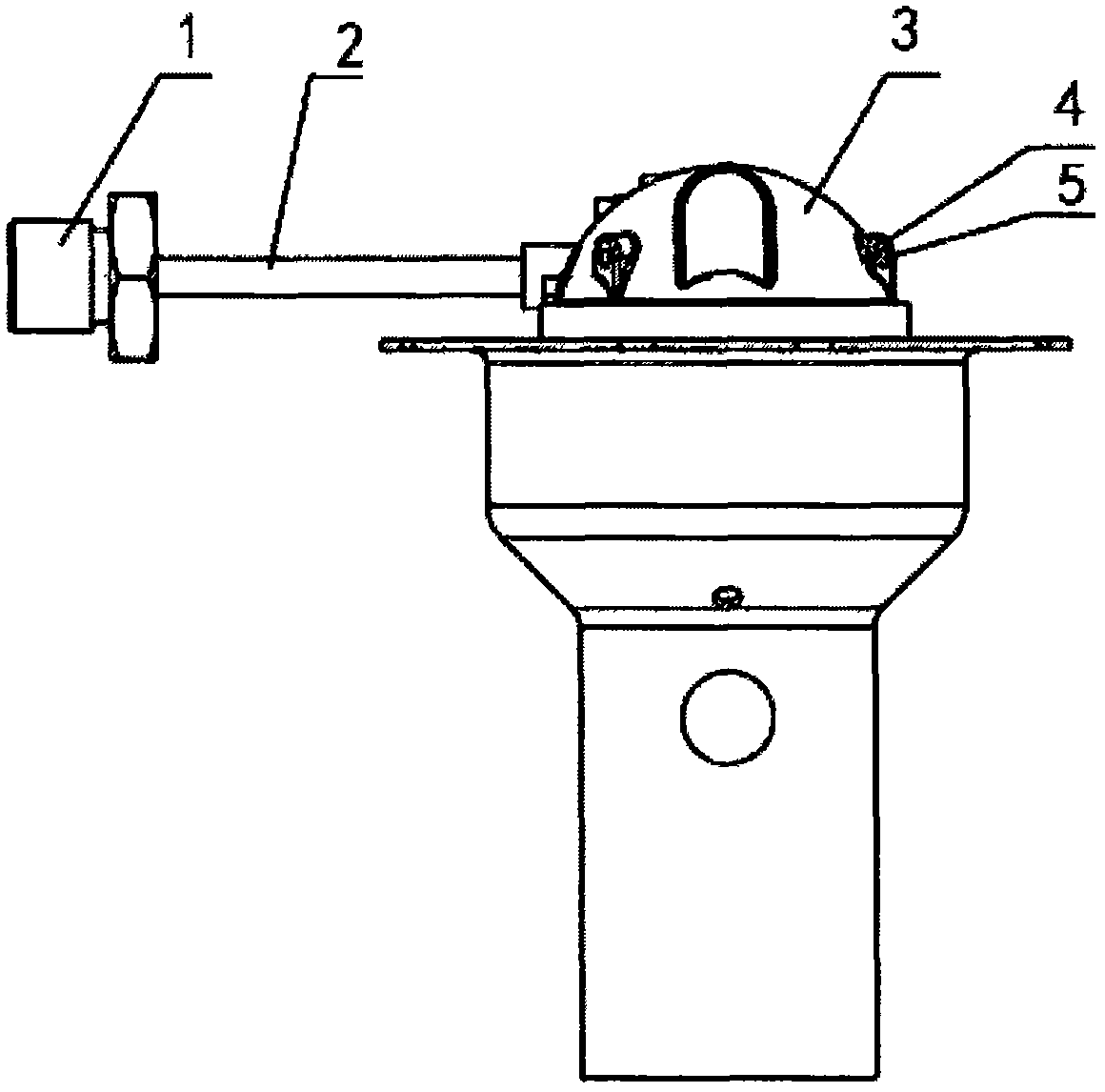

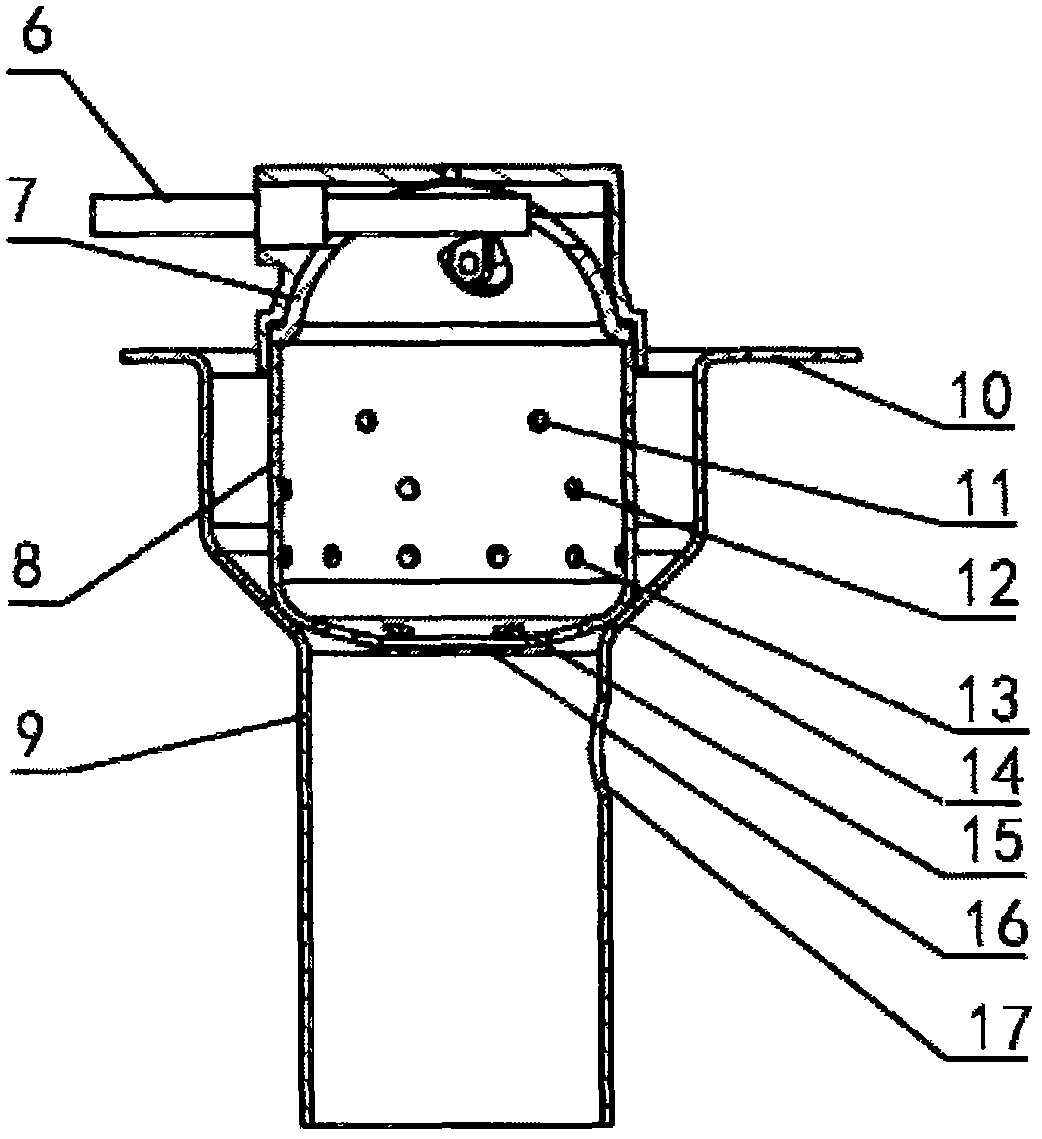

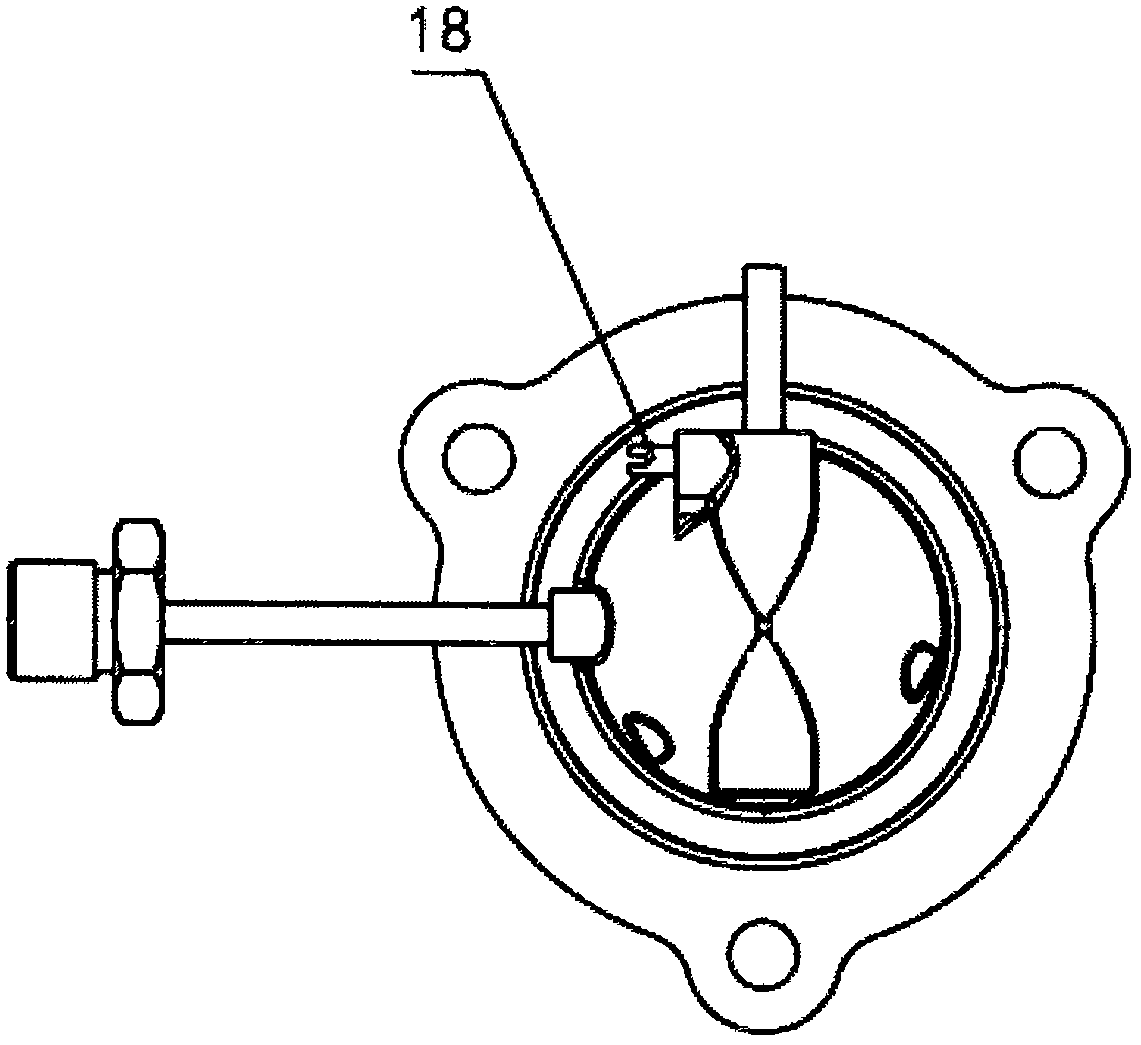

[0023] Combine below Figure 1 to Figure 3 , the present invention is further described:

[0024] A miniature atomizer for fuel atomization, ignition and combustion, including a fuel pipe rotary joint 1, an oil inlet pipe 2, an atomization cover 3, a protrusion 4, an air duct hole 5, a glow plug 6, an atomization net 7, a wind Cover 8, flame nozzle 9, mounting flange 10, first air inlet hole 11, second air inlet hole 12, third air inlet hole 13, welding hole 14, small gas outlet hole 15, large Gas outlet hole 16, flame detection hole 17 and set screw 18.

[0025] The oil pipe rotary joint 1 is used to connect the external fuel pipe, and the fuel is introduced into the oil inlet pipe 2. The oil inlet pipe 2 is made of seamless stainless steel pipe, and the inner diameter of the pipe cannot exceed 3mm. The cover 3 is welded together by welding. The fuel flows into the atomizing cap 3 through the oil pipe rotary joint 1 and the oil inlet pipe 2 . The atomizing net 7 is placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com