Preparation method of distributor of reaction tank nozzle

A production method and reactor technology, which is applied in the production field of reactor nozzle distributors, can solve the problems of small atomization area, insufficient atomization, and uneven spatial distribution, and achieve high atomization area, improved transparency, and physical and chemical volume big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

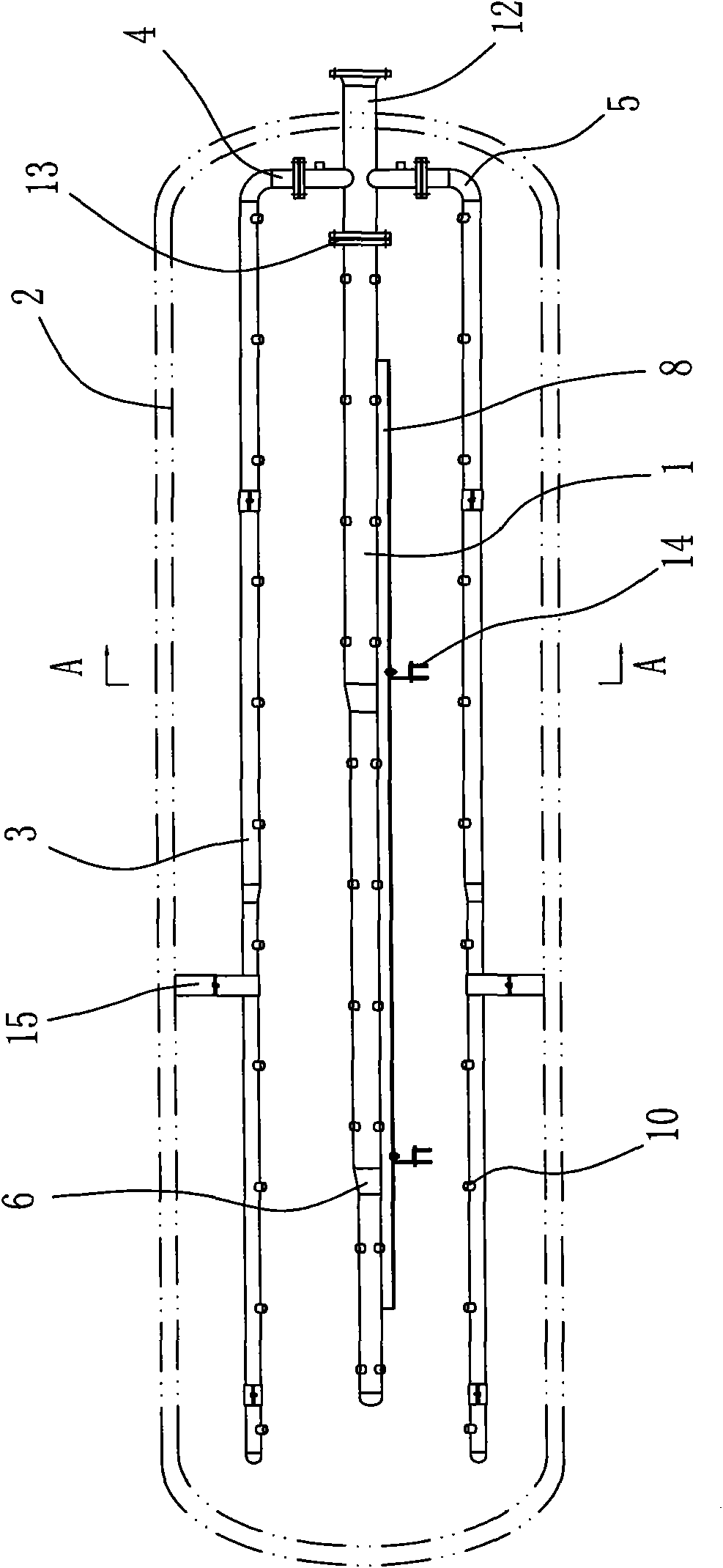

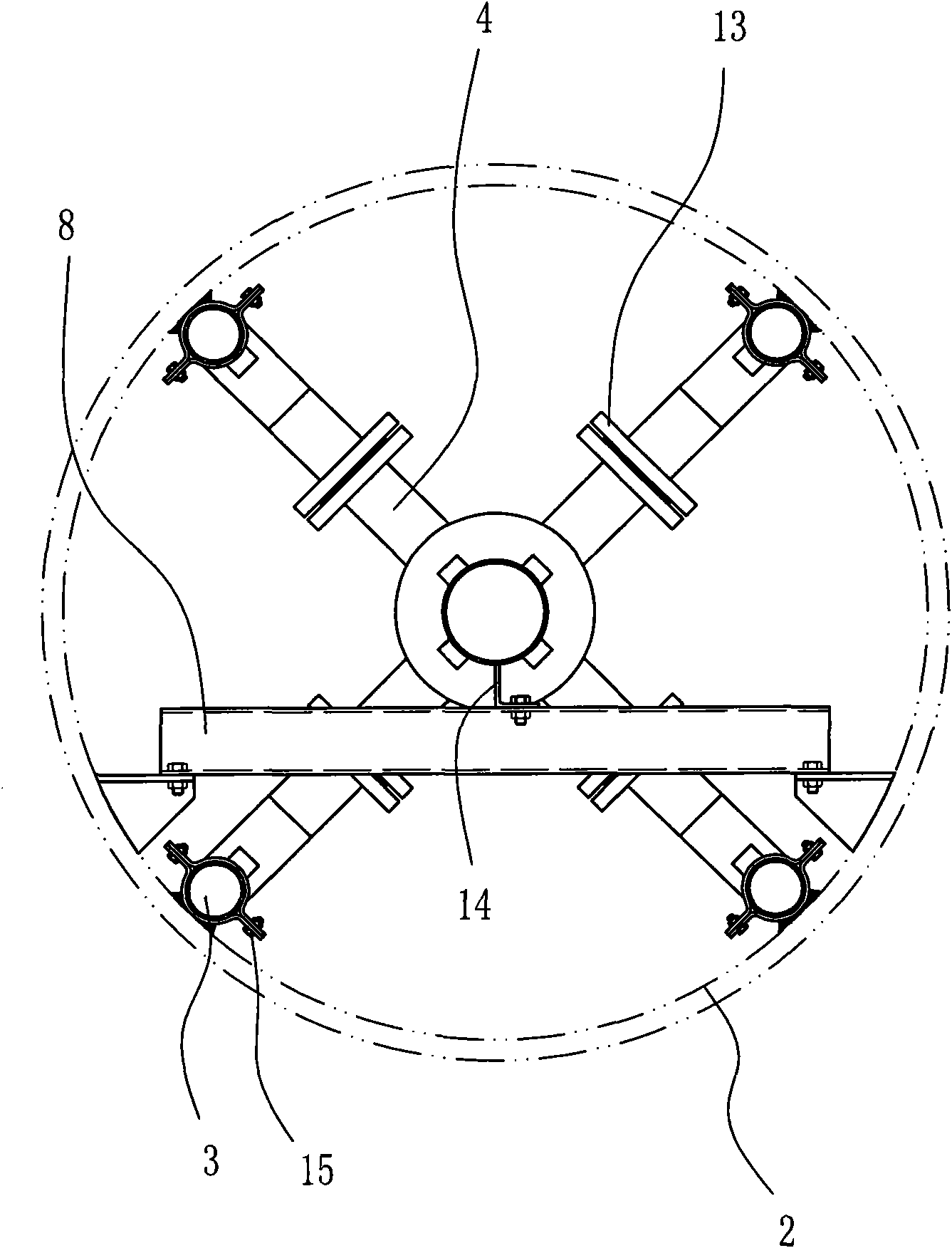

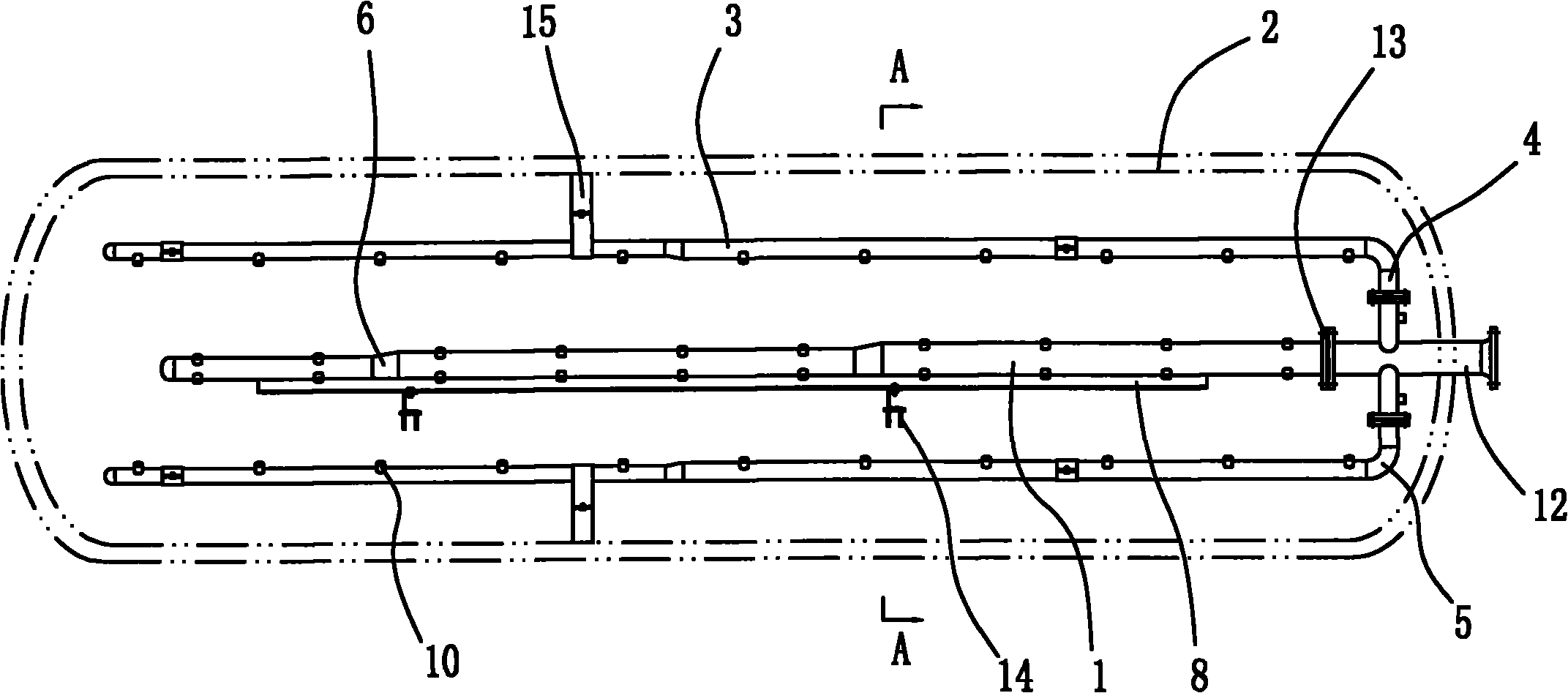

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

[0023] refer to figure 1 and figure 2 , the method for making the reactor nozzle distributor provided by the invention is specifically described as follows:

[0024] The method for making the nozzle distributor of the reaction kettle provided by the present invention, the parts used include the feed port 12, the connecting pipe 4, the elbow 5 and a plurality of liquid flow pipes 1, 3, wherein the number of the liquid flow pipes 1, 3 is 5 ~13: one of them is the middle pipeline 1, which is on the same straight line as the feed inlet 12; In addition, the diameters of the liquid flow pipes 1 and 3 gradually decrease with the direction of the liquid flow; adjacent liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com