Cold mist system

A technology of cold mist and refrigeration units, which is applied in air conditioning systems, refrigerators, refrigeration components, etc., can solve the problems of cooling water heating up, the temperature cannot keep temperature synchronization, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

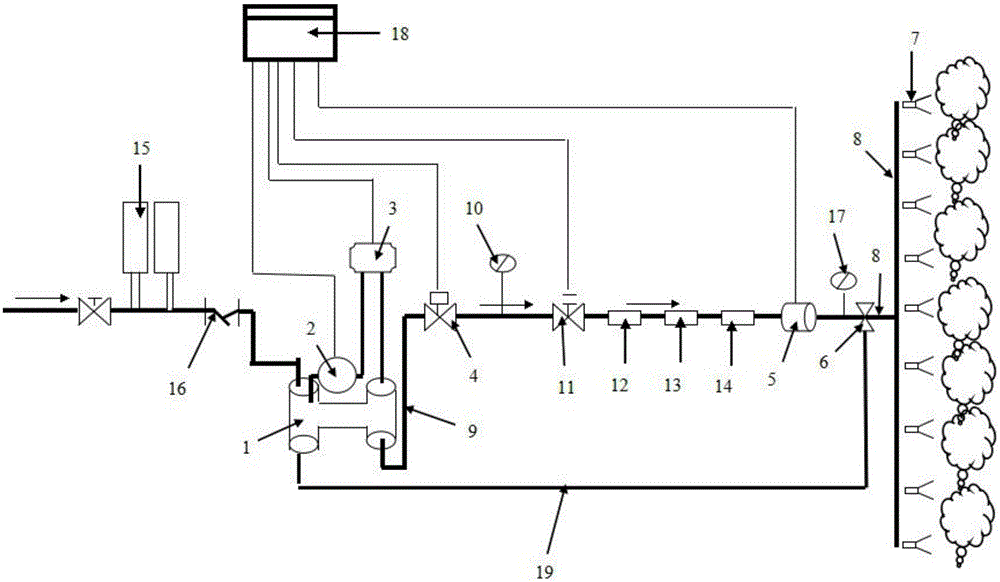

[0028] Embodiment 1 is a preferred embodiment of the present invention, as shown in the accompanying drawings: a cold mist system, including a water tank 1, a refrigeration unit connected to the water tank 1 through a pipeline 9 and a high-pressure sprayer, the refrigeration unit is preferably a refrigeration compressor 3 . A circulation pump 2 is connected between the water tank 1 and the refrigeration compressor 3, that is, one end of the circulation pump 2 is connected to the water tank 1, and one end is connected to the refrigeration compressor 3, and the refrigeration compressor 3 is connected to the water tank 1, and the circulation pump 2 makes the water tank 1 The water in the inside is continuously circulated and refrigerated between the circulation pump 2, the water tank 1 and the refrigeration compressor 3. Described high-pressure sprayer comprises high-pressure pump 5 and the atomizing nozzle that is connected with high-pressure pump 5 by high-pressure delivery pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com