Intelligent supercharging device and method for low-temperature thermal insulation container

A technology of a low-temperature heat insulation and pressurization device, which is applied to container filling methods, container discharge methods, pressure vessels, etc., can solve the problems of insufficient liquid supply, long pressurization time, poor pressurization effect, etc., and achieve a simplified structure of the device, The effect of shortening the pressurization time and ensuring safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

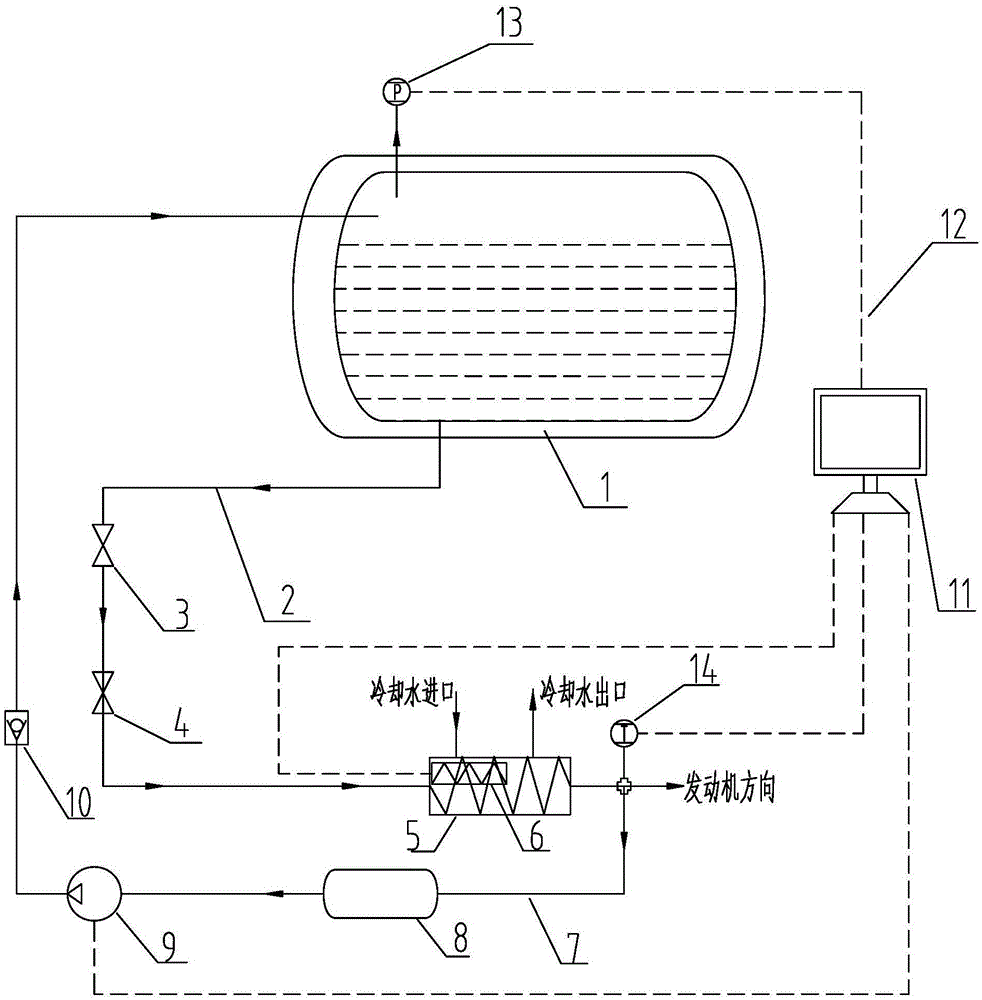

[0033] Such as figure 1 The shown intelligent supercharging device for a cryogenic heat insulating container includes a cryogenic heat insulating container 1 and an electrical control system 11, and its special features are:

[0034] The liquid outlet at the bottom of the low-temperature heat-insulated container 1 is connected to one end of the shut-off valve 3 through the liquid outlet pipeline 2, and the other end of the shut-off valve 3 is connected to the input end of the overflow valve 4 through the liquid outlet pipeline 2, so The output end of the overflow valve 4 is connected to the liquid inlet of the vaporizer 5 through the liquid outlet pipeline 2, and a heater 6 is installed in the vaporizer 5;

[0035] The outlet of the carburetor 5 is divided into two paths, one of which is connected to the engine, and the other is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com